Nanyang Liaoyuan Road Construction Machinery Co.,Ltd.

- Home

- Companies

- Nanyang Liaoyuan Road Construction ...

- Products

- Liaoyuan - Model JJW3000 - JJW4000 - ...

Liaoyuan - Model JJW3000 - JJW4000 -Asphalt Mixing Plant

Asphalt Plant JJW Series is a large capacity hot mix energy efficiency asphalt plant launched by Liaoyuan in 2018. JJW series asphalt plant uses vertical drying tower instead of traditional drying drum, greatly saving electricity and fuel, making it a milestone product in asphalt mixing industry. By adopting cutting edge design, latest patents, precise and efficient weighing technology, JJW series energy efficiency asphalt plant enjoys great advantages in operation cost control, resource saving and clean production. JJW series energy efficiency asphalt plant is designed for road pavement and rehabilitation in capital and large cities where roads density is very high.

Most popular related searches

asphalt plant

concrete batch mixing plant

pollution emissions

weighing technology

aggregate product

belt conveyor

asphalt recycling

hot mix asphalt

enclosed belt conveyor

aggregate waste

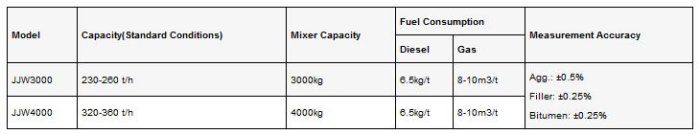

- Product Capacity: 260 t/h ~ 360 t/h

- Highlights: energy efficiency, recycling asphalt system optional, vertical drying tower instead of drying drum; hot mix plant.

- Substitute traditional drying drum with vertical drying tower, saving electricity (about 60kW/h),fuel and lubricant, lowering production cost to a large degree;

- Intelligent and precise control over cold aggregate feeding and hot aggregate dosing; no overflowed hot aggregate during production, no redundant hot aggregate after production; eliminating waste of aggregate and fuel;

- Adopt Synchronized Decrement weighing method, and minimize the weighing error; dynamic weighing accuracy: aggregate and filler<1%, bitumen<0.8%; static weighing accuracy: aggregate±0.5%, filler and bitumen±0.25%;

- Whole production process is fully enclosed; aggregate feeder, belt conveyor, loading chamber and mixing tower are all enclosed; minimal dust and pollutant emission; safe and clean;

- Batch cycle time is reduced to 40 seconds, higher efficiency and 15% more productive than that of same model batch mixing plant;

- Hot recycling device(recycled asphalt pavement processing device) can be added if required.