ATM Arno Cut - Scrap Shears

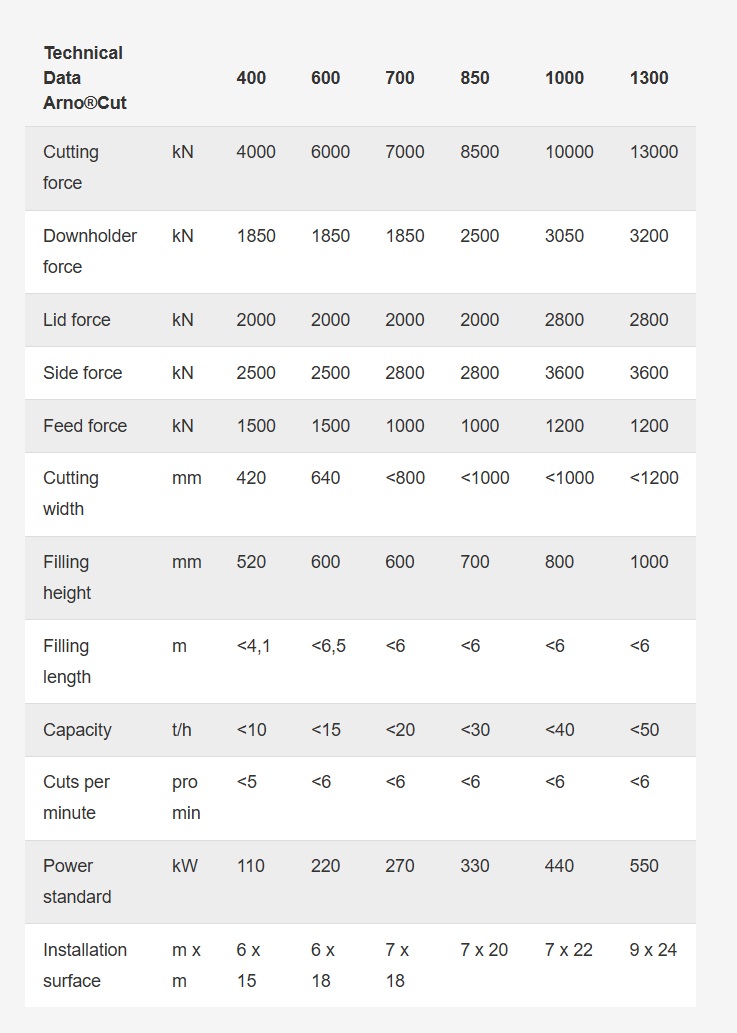

Arno®Cut Series Scrap Shears are the best choice for pre-compacting and cutting of metal plates and components, car body parts and similar light- to medium weight scrap. Even steel rails can be cut with special notch blades. The machines are available in six sizes from 4,000 to 13,000 kN shear force. All compacting chamber wear plates are made of Hardox 400 up to Hardox 500 and guarantee highest quality and a long service life. Cutting cycles are optimised by linear transducer systems in the cylinders. The need for an elaborate foundation is avoided thanks to the monobloc construction. A centralized lubrication system, various clogging indicators and fault analysis guarantee simple maintenance. Comfortable operation with two joysticks and a multifunctional display in a soundproof, airconditioned cab make the scrap shear a workplace with the highest level of safety and productivity.

Wear plates

Depending on the purpose of the shear we offer straight wear plates as well as wear plates with special square or trapezoid-shaped profiles in various material qualities.

Ergonomic workplace

A helm seat with 2 joysticks, monitor visualisation and video surveillance situated in an air-conditioned cabin set new standards in workplace design.

Traversing lateral compressor

Two separately controllable side cylinders make it possible to traverse the lateral compressor up to 15° in order to pre-compress bulky constructions and materials.

Hydraulic tank

The bicameral system guarantees the supply of filtered and cooled oil to the performancecontrolled hydraulic pumps.

PZT Pump activation technology

The pump activation technology regulates the required quantity of oil per cylinder, thereby minimising the neces-sary drive energy of the press.