- Home

- Companies

- Aura Verde LDA

- Products

- Aura Verde - Organic Oil Binder

Aura Verde - Organic Oil Binder

We specialise in organic, biological oil absorbents made from premium coco peat and in exporting coconut shell chips used as feedstock for activated carbon. If you want a renewable, non‑toxic, plant‑based sorbent for hydrocarbon spills—or a consistent coconut shell supply for your carbon line—you’re in the right place.

WHAT WE DO

• Organic/biological oil absorbent (coco peat): supplied loose for spreading, or pre‑filled in socks/booms/pillows for fast spill response.

• Coconut shell chips for activated carbon: consistent size ranges, low fines, stable moisture; spec matching on request.

• Coir substrates (horticulture): short coir fiber and coir chips—still available for growers who need dependable coco media.

• Private label & custom recipes; sold per liter. Our popular pack is the 75 L bag, alongside big bags and palletised units.

WHY A COCO‑BASED, ORGANIC OIL ABSORBENT?

Coco peat is a renewable by‑product of the coconut industry and forms a highly effective eco‑friendly oil absorbent. Properly prepared it is oleophilic and offers high uptake of oils and hydrocarbons. We supply:

• Universal grades for shop floors and yards (absorb oils, fuels and many non‑aggressive liquids).

• Oil‑only, hydrophobically treated grades designed to prefer oil over water, ideal for marinas, drains and water surfaces.

• Granulated/low‑dust options to improve handling in warehouses and workshops.

TYPICAL APPLICATIONS

• Spill kits and spill response programmes (automotive, transport depots, marine, mining, manufacturing).

• Routine maintenance: under machinery, generators, compressors and mobile equipment.

• Emergency response for hydrocarbon spills on soil, concrete or water (with oil‑only grade).

• Storm‑water and containment: use socks/booms to intercept oily runoff.

• Remediation projects: blend into contaminated soil as a biological, carbon‑rich absorbent before removal—always follow local regulations.

PERFORMANCE & SAFETY

• High surface area for rapid wicking and retention of oils, diesel and lubricants.

• Plant‑based, biodegradable absorbent; free from added silica or glassy mineral grit.

• Available with hydrophobic treatment for oil‑on‑water situations; universal grades for general maintenance.

• Supplied with SDS and test data upon request. Absorbency varies by fluid and grade—ask for a sample to validate in your process.

• Disposal must follow local law; used absorbent typically takes on the classification of the liquid absorbed.

WHICH OIL ABSORBENT PRODUCTS WE OFFER

• ECO MAX PRO: High-efficiency, floatable organic oil absorbent designed for marine environments and emergency response.

Absorption: 8–10× its own weight

Stays afloat on water

Ideal for heavy & light oils

Fast response for critical spill situations

100% natural and fully biodegradable

• ECO BALANCE: Versatile indoor/outdoor oil binder for daily industrial spill control in workshops, production areas and logistics centers.

Absorption: 6–7× its own weight

Perfect for concrete, metal and soil

Low dust, easy spreading

Suitable for maintenance and facility teams

Hydrophobic and safe to use

• ECO BASE: Cost-effective absorbent for routine cleanup, transport vehicles, municipal use and landfill operations.

Absorption: 4–5× its own weight

Ideal for dry sweeping

Great for large areas and frequent spills

Economical for high-volume applications

Environmentally friendly mineral-free alternative

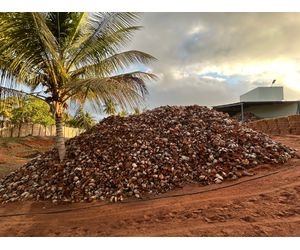

COCONUT SHELL CHIPS FOR ACTIVATED CARBON

We export coconut shell chips for steam activation to produce GAC/PAC. Shell is prized for high hardness and excellent microporosity in the finished carbon. We focus on:

• Consistent chip sizes to your feeder and kiln (common industrial ranges available; custom sieving on request).

• Clean, well‑screened material with controlled moisture and minimal fines.

• Reliable container loading and export documentation to keep carbon plants supplied without interruption.

SUSTAINABILITY YOU CAN MEASURE

• Circular economy: we upcycle coconut by‑products into value‑adding materials—organic oil absorbents and shell chips for activated carbon.

• Lower footprint per litre than mined mineral absorbents and sphagnum peat, with no peat bog extraction.

• Space‑efficient logistics: compressed formats and smart container loading reduce transport emissions per litre.

PACKAGING & FORMATS

• 80 L bags (our standard retail/wholesale unit—priced per liter for transparent comparisons).

• 250 L pressed bales of Coir Fiber (long/short hair)

• Big bags (bulk), palletised loads, or full 40HC containers.

• Spill‑response formats: absorbent socks, booms and pillows filled with our coco‑based sorbent.

• Coconut shell chips in bulk bags or sacks; palletised for safe handling.

QUALITY MANAGEMENT

• Batch traceability from screening to packing.

• Routine checks for moisture, particle size distribution, and visible impurities.

• Optional washing for horticultural coco peat grades; oil‑only absorbent grades use specific blending and surface treatments.

• Photos and loading reports available before shipment.

HOW WE WORK

• Fast quotes with per‑liter pricing, landed‑cost options and realistic lead times.

• Clear Incoterms (EXW, FOB, CFR/CIF, DAP), documentation pack, and logistics support.

• Sampling programme: test the organic oil absorbent or shell chip grade you intend to buy, in your own use case.

• Support after delivery: application tips, spill‑response guidance and optimisation of formats (e.g., switching from loose absorbent to socks/booms where that saves time and labour).

WHO WE SERVE

• Spill kit assemblers and industrial distributors.

• Maintenance, HSE and facilities teams in factories, depots and ports.

• Marine contractors and marina operators (oil‑only grades).

• Carbon manufacturers seeking stable coconut shell chip supply for activated carbon.

• Professional growers who still rely on our coco substrates.

COMPLIANCE & CLAIMS

We avoid overstating claims. If you need a particular test method, certificate or audit, tell us—our team will align to your requirements where available. Always follow site safety rules and local environmental regulations when using or disposing of absorbents.

WHY AURA VERDE

• Focused portfolio: organic/biological oil absorbents and coconut shell chips—with coco substrates as a complementary line.

• Practical, responsive service from quote to container arrival.

• A partnership approach: we aim for the right grade and the right format for your task, not a one‑size‑fits‑all product.

NEXT STEPS

Tell us your application (spill type, environment, format), preferred packaging (e.g., 80 L bags or socks/booms or pressed bales), and destination. We’ll recommend a grade, send a firm quote and timing, and ship under the terms you prefer.