MetraSCAN - Model R-Series -Automated Quality Control 3D Scanner

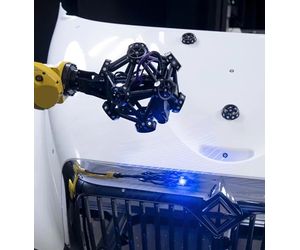

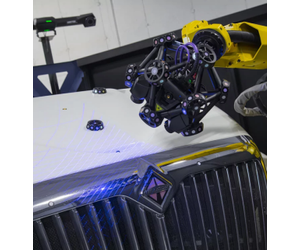

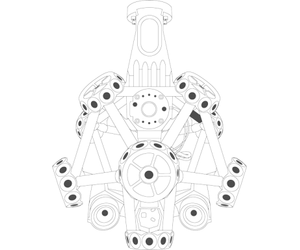

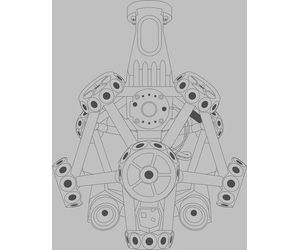

Designed for automated quality control applications, the R-Series 3D scanning solutions are perfect for manufacturing companies who want to increase their productivity by measuring more dimensions on more parts without compromising on accuracy. The MetraSCAN 3D-R is a powerful, innovative robot-mounted optical CMM scanner that can be seamlessly integrated into automated quality control processes for at-line inspection in mass production. Its cutting-edge technology enables manufacturing companies to detect quality issues faster. The CUBE-R leverages the power of the MetraSCAN 3D-R in a high-productivity industrial measuring cell that is designed to be integrated into factories for at-line inspections. Compared to traditional CMMs, the CUBE-R is much faster, providing a gain in productivity and better efficiency.

The R-Series product line was created to maximize quality control productivity and eliminate bottlenecks at the CMM through 3D scanning processes.

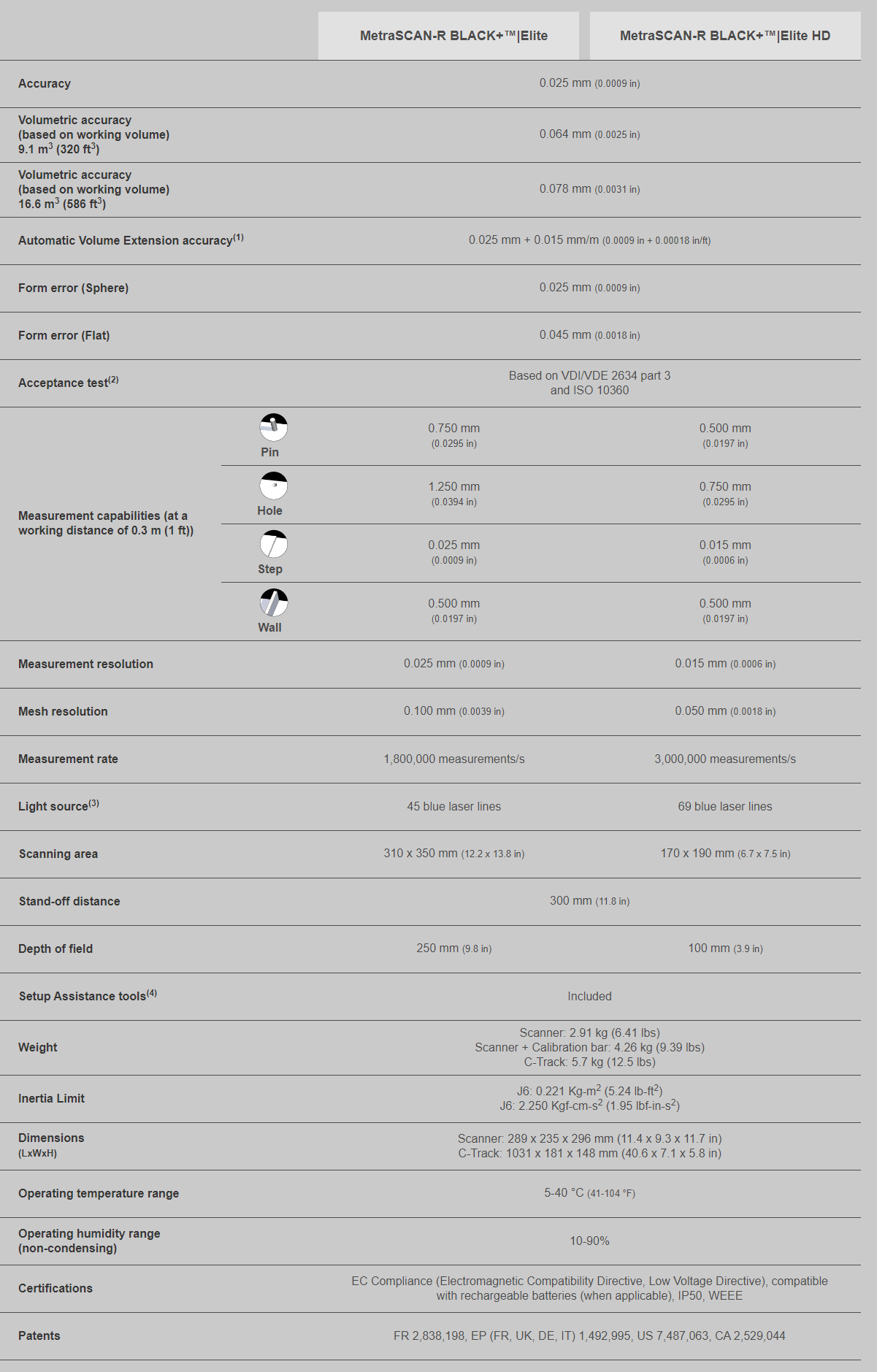

- Accuracy of 0.025 mm (0.0009 in)

- Certified ISO 17025

- Repeatable results

- Short cycle time

- Worldwide support

- High resolution

The MetraSCAN 3D-R enables the measurement of hundreds of parts per day. Perfect for at-line inspection in mass production, it brings quality control as close to the part as possible. From easy integration to quick and simple installation, the MetraSCAN 3D-R helps you speed up your automated quality control processes—and accelerate your time to market.

- High measurement rate

Up to 3,000,000 measurements/second for short cycle times - Fast measurement speed

Regardless of surfaces, trims, and geometric features - High-density scanning area

69 laser lines

Due to its metrology-grade accuracy, repeatability, and resolution, the MetraSCAN 3D-R delivers high-quality results, whether on surfaces, trims or geometric features. The MetraSCAN 3D-R is free from rigid measurement setups, making it a 3D scanner engineered for industrial automation in shop-floor conditions. Thanks to the C-Track optical tracker that enables dynamic referencing, both the 3D scanner and the part can move during inspection—maintaining part alignment as well as measurement accuracy and reliability.

- Shop-floor accuracy with dynamic referencing

0.025 mm (0.0009 in) in shop-floor conditions, regardless of instabilities, vibrations, and thermal variations - Reliable acceptance tests

Based on VDI/VDE 2634 Part 3 standard

Based on ISO 10360 standard

ISO/IEC 17025: 2017 accredited laboratory - Volumetric accuracy

0.078 mm (0.0031 in) - High resolution

0.015 mm (0.0006 in)

Combining the power of optical and blue laser technologies, the MetraSCAN 3D-R has the capability to both generate highly efficient 3D scans on shiny surfaces or on objects with variations in reflectivity and measure various part sizes and different surface geometries. The MetraSCAN 3D-R is available as a custom solution with an industrial robot or as a completely turnkey measuring solution with Creaform`s CUBE-R.

- Blue laser technology

Ideal for shiny and reflective surfaces - Configurable and customizable portfolio

16 configurations - Large part size range

Perfect for various part sizes and geometries - Custom integration possible

Due to its operational simplicity, compatibility with metrology software, and off-line programming, the CUBE-R is a CMM that is accessible to all, regardless of the level of expertise or experience. The user interface makes it simple for operators, who are non-experts in robotics nor metrology, to measure parts regardless of size, shape, or complexity. Once the measurements are completed, quality control engineers can focus on analyzing and reviewing the results.

- Accessibility to shop floor operators

No expertise in robotics nor metrology required - Short and easy deployment

3-day installation - Software independence

Compatible with metrology software - Digital twin environment

VXscan-R scanning intelligence and robot path programming

The MetraSCAN 3D-R can be used for all types of quality control or quality assurance application thanks to leading-edge performance levels.

Accuracy

0.025 mm (0.0009 in)

Volumetric accuracy

0.078 mm (0.0031 in)

Measurement rate

Up to 1,800,000 measurements/s

Part size range (recommended)

Up to 3 x 1.5 m (9.8 x 4.9 ft)

The MetraSCAN 3D-R is a high-performance robot-mounted optical CMM scanner designed for automated quality control applications. It can be seamlessly integrated within any production workflow to carry out at-line inspections right on your shop floor. The MetraSCAN 3D-R not only increases your productivity but also improves your inspection accuracy on all types of parts, regardless of size, geometry, finish or reflectivity. It’s a must for your automated quality control strategy.

Innovating technology that provides accuracy, simplicity, portability as well as real speed to your metrology-grade applications.

Creaform’s metrology centres are located around the world and offer the following services* in different languages:

- 24/7 support for the MetraSCAN 3D-R and CUBE-R

- Software technical support helpline

- 3D scanner basic and advanced repair

- Equipment maintenance, tuning and calibration

- Loaner services

- 3D scanner component replacement

- Warranty renewal

* Services may vary depending on each metrology center.

Creaform designs, manufactures, and calibrates the MetraSCAN 3D-R with the most sophisticated quality management system and according to internationally recognized standards, the ISO 9001 and ISO 17025.

The MetraSCAN 3D-R’s acceptance test is based on VDI\VDE 2634 and conducted in an ISO 17025 accredited laboratory to guarantee traceability aligned with international standards.

Each MetraSCAN 3D-R is delivered with a personalized certification and fully documented test results.

Product and support based on international metrology standards

At Creaform, product and service quality is our top priority. Being pioneers in portable 3D measurement technologies, we are committed to exceeding our customer requirements by developing innovative solutions.

We are invested in continuously improving processes, setting new standards for the industry and ensuring full satisfaction of our clientele.