- Home

- Companies

- Quartz Imaging Corporation

- Products

- Quartz PCI-AM - Automated Semiconductor ...

Quartz PCI-AM - Automated Semiconductor Metrology Software

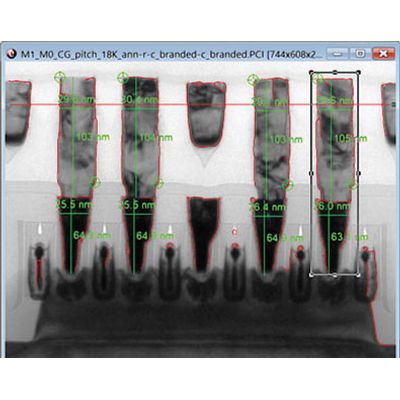

Quartz Imaging Corporation has been at the forefront of providing innovative metrology solutions for the semiconductor industry for over three decades. Their Quartz PCI-AM software is a versatile tool designed for automated semiconductor metrology, leveraging the latest advancements in AI technology to enhance microscopic image analysis. The software supports metrology across both cross-sectional and top view images from Scanning Electron Microscopes (SEMs) and Transmission Electron Microscopes (TEMs), crucial for semiconductor manufacturing and process development environments. This software employs multiple edge detection techniques, including an advanced model utilizing deep learning algorithms, ensuring accurate measurements across various image types. A key feature of PCI-AM is its automation levels, allowing users to execute complex measurements with minimal setup, significantly boosting efficiency and consistency. This tool not only accelerates measurement processes but also enhances reproducibility by minimizing human intervention in defining measurement points.

Automated Semiconductor Metrology

PCI-AM performs metrology in both cross-section and top view images from SEMs (X-SEM) and TEMs in semiconductor laboratory, process development and engineering environments. Multiple edge detection techniques are employed depending on the nature and source of the images, including our most recently introduced Advanced Model based on deep learning. This is vastly different from other tools designed for in-line metrology using top view images.

Very little set-up is required before you can be making fast, efficient automatic image measurements. Therefore, it is practical to use the PCI-AM tools to measure individual images and as an aid to manual measurements, in addition to being able to measure large batches of images.

Not only does PCI-AM save time, it also improves measurement consistency among multiple users because the edges and measurement points are determined automatically by the system rather than by human judgment.

Trenches (Spaces) and Pillars (Lines)

CD Width

Angles – Sidewall and Center

Multiple Regions in Feature

Line Edge Roughness

Line Width Roughness

Distances Below and Above Reference Line

Averages of the Above Measurements

Shapes

Area and Perimeter

Aspect Ratio

Major and Minor Axes

Collinearity

Ideal Shape Deviation

Tilt

Macro Cell

Multiple Measurements in Complex Features with a Single Click

Other Valuable PCI-AM Features

"Point and Shoot" Horizontal and Vertical Measurement Tools Utilize Edges

Regular PCI Measurement Tools will "Snap" to the Edges in PCI-AM

Predetermine the Number and Exact Location of CD Measurements Relative to the Reference Line

Advance Edge Detection Model