AD Systems - Model CT10 -Automated Steel Test Rod Corrosion Reader

A new instrumental approach for measurement of corroded surface area has been developed by AD Systems in which the exact percentage of corroded area is accurately determined by an automatic instrument reducing test subjectivity. The operation is based on a homogeneous lighting source, CCD camera, specimen rotation system, and specially designed application software. With CT10 the corrosion rating is now very repeatable and fully documented. ASTM / NACE Corrosion Rater, ASTM D665, D7548, NACE TM0172, IP 135, ISO 7120, JIS K2510.

The CT10 test is simple and straight forward. The iron specimen is prepared according to the standard test procedure (using CB10 corrosion bath) and is placed in the test chamber of the CT10. The operator enters sample information, using an intuitive graphical interface with touch screen panel, and starts a specimen scan. The specimen is rotated in specially designed lighted chamber and several images are taken by digital camera. The software builds a flat image of the specimen suface, analyses it and calculates the percentage of the corroded area. This percentage is reported and translates it into a NACE rating.

A detailed test report is ready in less than 5 minutes.

- NACE TM0172

- ASTM D665

- ASTM D7548

- IP 135

- ISO 7120

- JIS K2510

- Refineries

- Mineral and steam turbine oils

- Pipeline and terminals

- Iron Corrosion testing

- Quick, accurate and objective rating

- Automatic specimen diameter verification

- Compact design, robust construction, installed in minutes

- The results are saved in an internal database and can be printed, transferred to a USB memory stick and/or sent to a LIMS

- Every test is fully documented and traceable

Operation is based on a homogeneous lighting source, CCD camera, specimen rotation system, and specially designed Windows CE® application software. Specific light is emitted onto the surface of the specimen. The specimen is rotated and several images are taken. The software builds a flat image of the specimen surface, calculates the percentage of the corroded area and then translates it into a NACE rating. A detailed test report is ready in less than 5 minutes.

A new instrumental approach for measurement of corroded surface area has been developed by AD Systems in which the exact percentage of corroded area is accurately determined by an automatic instrument. Automation dramatically reduces operator subjectivity.

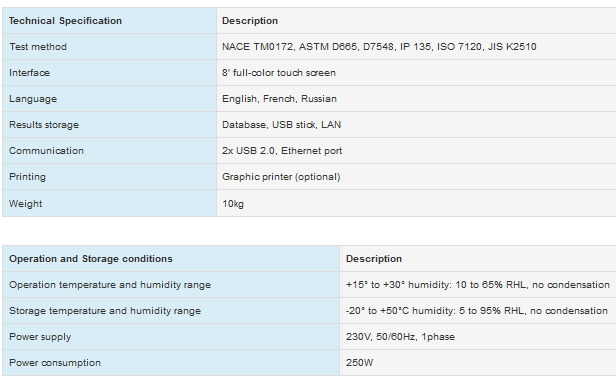

All details related to each test are recorded and stored into a local database. Complete test report including sample ID, operator name, date/time, standard, Procedure, Test duration, d egree of severity of rusting and picture of the rod. The result can be printed on optional printer. Multi-criteria search function facilitates retrieval of any test report in the database. Versatile communication features allow complete test report storage on a USB memory stick and/or transfer it to a LIMS when the CT 10 is connected to a LAN.