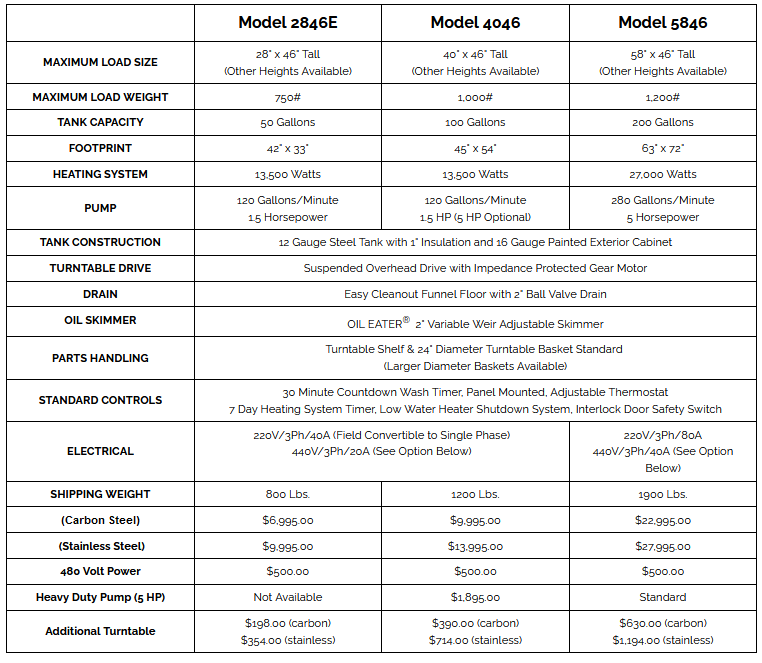

EMC Powerjet - Model 2846 -Automatic Cabinet Style Spray Parts Washer

The POWERJET Model 2846E is an automatic, cabinet style spray washer with a 25 inch diameter turntable. An ideal for parts cleaner for general purpose cleaning. Common applications include engine and transmission rebuilding, general maintenance/repair, and degreasing of machined parts. Easy to operate and inexpensive to maintain, the 2846E has all the standard Powerjet® features listed below.

- 25" Turntable

- 50 Gallon Tank

- Insulated

- Carbon Steel

- Stainless Steel

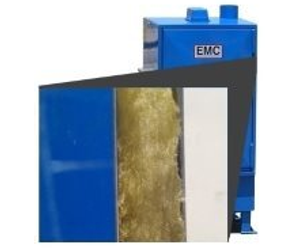

- Thermal Guard® Energy Saving/Heat Retention System: Fully insulated parts washer cabinet and roof, double wall construction, and pressure controlled vent damper with coalescer keeps the heat and cleaning solution in and the energy bills down. Solution

- Solution Saver®/Oil Eater®: Full flow 100% filtration using industry standardized filters and the OIL EATER®keeps your solution cleaner longer. Minimizing particulate and oil build up makes for cleaner parts and lower operating costs.

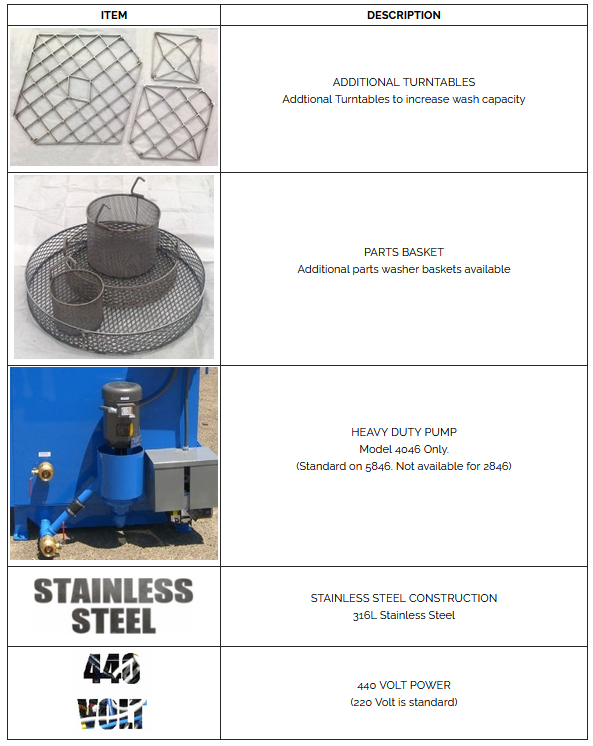

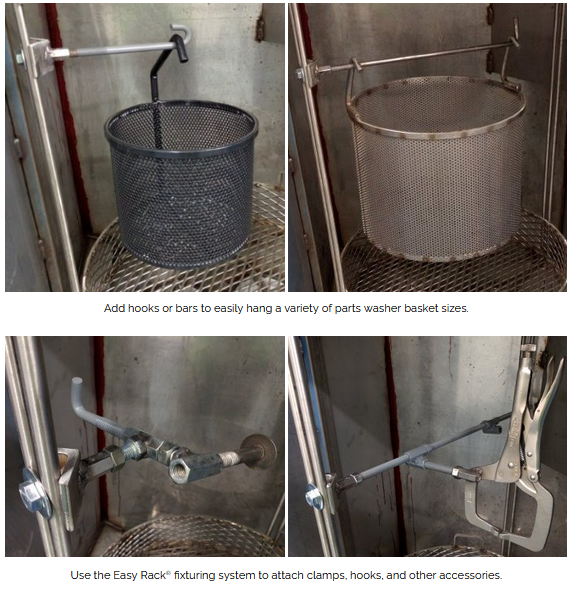

- Easy Rack® Fixturing System: The Easy Rack® provides almost unlimited part loading combinations. Easily field adaptable for individual needs. Multiple turntables and baskets are available.

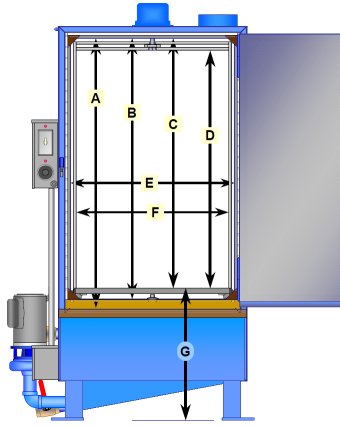

- Precision Targeting Spray System: Four sided, 360 degree coverage with up and down aiming jets on slightly different planes to target your parts, not each other. Combined with the JETPORT®, provides spray coverage throughout the cabinet wash area.

- Industry Standardized Components. Most parts are available from major industrial supply houses. You are not held hostage by the high mark up on "captive" parts only available by the original equipment manufacturer.

- One Year Warranty on Parts & Workmanship.

- Maximum Wash Area: 28" x 46" Tall, 25" Diameter Turntable

- Filtration System: Full Flow Filtration

- Tank Capacity: 50 U.S. Gallons

- Maximum Rotor Capactiy: 600 lbs

- Heavy Duty Centrifugal Pump: 120 Gallons Per Minute

- Stream Jets: 72 Straight Jets, 4 Sides, 360° Coverage

- Heating System: 13,500 Watt

- Timing System: 7 Day Heating System Timer

The Powerjet Automatic Parts Washer comes standard with insulated wash cabinet, full flow filtration, Low Level Heater Shutdown, and 7 Day Heating System Shutdown. Options for the Powerjet® are listed below. Pricing of accessories is on the specification/quote forms for each model of washer.

THERMAL GUARD ENERGY SAVING SYSTEM

All Powerjet® Cabinet Style Parts Washers are fully insulated for energy efficiency. Who would purchase an un-insulated hot water heater? Combined with our cabinet vent damper and positive door seal, the Powerjet is designed to minimize energy costs while allowing you to maintain your optimum operating temperature.

SOLUTION SAVER FLUID MANAGEMENT SYSTEM

The Powerjet® comes with many features that keep your wash solution clean and prolongs the useful life of the solution. First, there is a 100% full flow filtration. Since your parts are only as clean as your wash solution, we have an economical, reusable bag filter system. Among the advantage are the prevention of fouling cleaned parts, the elimination of manifold jet clogging, and dramatically extended solution life. In addition, there is a variable weir skimmer for removing free floating material.

OVERHEAD TURNTABLE DRIVE SYSTEM

The Powerjet® uses an overhead drive system for the wash turntable. The impedance protected gear motor and bearing are located out of the solution. This eliminates the need for drive wheels used by many manufacturers that require routine replacement. And the suspended turntable is able to support weights with less strain and wear. The EMC turntables rotate smoothly no matter where the load is located.

EASY RACK UNIVERSAL FIXTURING SYSTEM

The Easy Rack® universal fixturing system provides limitless parts loading combinations. Quickly position and grip virtually any part for optimum nesting and cleaning exposure. Often rivaling conveyor washers in capacity, the Powerjet with its multi level loading capabilities outputs many more parts than a traditional washer.

HEAVY DUTY CONSTRUCTION

The Powerjet® is designed to be long lasting with minimal maintenance.

- 12 gauge mig welded tank with 16 gauge exterior painted insulated tank

- 120 gpm heavy duty pump

- 8" door hinges with lubrication fitting on heavy box tubing door frame

- 2" full ported ball valve drain and 2" full ported oil skimmer outlet

LOW WATER SHUTDOWN SYSTEM

All EMC Powerjet® Automatic Parts Washers have a low water shutdown system to protect the heater system from a low water condition that can burn out the heaters.

7 DAY HEATING SYSTEM TIMER

All EMC Powerjet® washers come with a 7 Day Heating System timer. Enables the washer to turn on or off unattended. Allows the machine to be hot when you arrive in the morning and shut down at closing time.

HIGH VOLUME PUMP & MANIFOLD SYSTEM

Our high volume pump coupled with our straight stream manifold system quickly cleans your parts with minimal downtime for nozzle cleanout or pump repair. The 120 GPM pump flood washes your parts under low pressure. Low pressure drastically reduce maintenance time on pumps, motors, and spray jets. See our Product Information Bulletin - Spray Jets & Automatic Parts Washers.

13.5 KW HEATING SYSTEM

When you want to use your parts washer, you normally want to use it NOW! Our 13.5 kilowatt heating system quickly heats up the solution to operating temperature.

OFF THE SHELF COMPONENTS

There`s nothing we hate more than buying equipment with lots of proprietary parts. Not only are the parts usually expensive, but they can sometimes take months to procure. All of our components such as contactors, motors, switches, heaters, are easily available through local industrial supply companies such as Grainger or McMaster-Carr and we are more than happy to supply you with the part numbers.

PROVEN DESIGN

We`ve built thousands of parts washers over the last 35 years, always sticking to our philosophy of building quality, production style machines. We`ve made a few improvements and modifications over the years, of course, but you can be sure that the model you purchase from us has been field tested and proven in a variety of applications and for many years.

NO PROPRIETARY DETERGENT/SOAP REQUIRED

You are not required to use any proprietary detergent/soap in our Powerjet® Parts Washers. We recommend you contact your current chemical/coolant/lubricant suppliers and see if they have a "Spray Washer" detergent. A spray washer detergent should contain defoamers, rust preventatives, and be safe for the material you are cleaning (an aluminum safe detergent usually works well).

Dimensions of the Powerjet® parts washers can be found here. Powerjet cabinet dimensions.

Extra tall parts washers are available. Below you can see tall parts washers made for specialized automotive parts cleaning. Custom size pricing is based on the base model and extra height added.

All Powerjet® parts washers can be installed with multiple turntable shelves.

Above is a Powerjet® parts washer model 2846 with an extra tall model 5846. Our wider parts washers can accommodate multiple wash basket.

When was the last time you purchased a non-insulated refrigerator? Or a non-insulated hot water heater? Probably not recently. However, many Automatic Parts Washers, which are essentially hot water heaters, are not insulated against heat loss. This is despite the fact that over the lifetime of a parts washer, heating costs are often substantially more than the initial purchase price of the washer.

For example, to heat 100 gallons of water 80° (approximate increase from ambient temperature to 150° operating temperature) requires approximately 17 Kilowatts of electricity. With electrical rates ranging up to $.20 per kilowatt-hour, when you factor in the faster temperature recovery rate each time the pump is activated and each morning when the parts washer is turned on, the energy usage over a one years period can be quite substantial. Insulation of the wash tank can dramatically cut energy usage, often saving up to $500 per year.

However, increased energy usage is not the only drawback of non-insulated parts washers. Uninsulated parts washers operating at normal cleaning temperatures (140 deg F to 180 deg F) have extremely hot surfaces, which can scald and burn personnel. In addition, this wasted heat is added to the workspace, increasing building cooling costs and making for an uncomfortable work environment.

Finally, and often most critical, an insulated parts washer is more likely to maintain it`s proper operating temperature under heavy usage conditions. The constant opening of the wash cabinet door and on/off action of the pump accelerates the drop in temperature of the wash solution overwhelming the ability of the heating system to maintain temperature.

Partial insulation of wash cabinets, offered by some manufacturers, is usually done with prefabricated panels attached to easily accessible areas. This is better than nothing but is somewhat akin to leaving the refrigerator door only slightly open. Full insulation of the walls, roof, and door provide the most efficient and costs effective solution for cleaning efficiency, energy conservation, and operator safety.

Most industrial automatic parts washers use either fan style spray jets or straight stream spray jets. What`s the difference? Let`s suppose you are at home hosing down your driveway when you come across something difficult to remove. Most of us would simply adjust the nozzle to switch from the weaker, but wider, fan spray to the concentrated high impact straight stream.

This example demonstrates how a fan style jet has a wide coverage area but requires high PSI to generate much impact force. Furthermore, if the distance to the target increases without the PSI increasing, the fan style jet acts more like a mister as much of the impact force is lost to air resistance. Increasing PSI using larger horsepower pump motors will improve cleaning efficiency but can lead to other problems. Fan style spray jets under high pressure can induce air currents and blow around delicate parts. Also, since the fluid leaves a fan style jet in the shape of a "V", and parts washers need the coverage of several fan jets, the best cleaning is at a distance exactly where the "V"s meet. Too close to the fan jet and some areas are left in an untouched dead zone. Too far away and much of the impact is lost as the spray from adjacent jets collide. In addition, the unusable dead zone before the fan jets converge requires a larger washer cabinet for the same size wash load. To overcome these problems, some fan jet parts washer designs use adjustable or rotating wash manifolds.

The straight stream jet design has a high impact force at varying distances since the area being targeted is small. Good coverage requires many straight jets at close spacing. This calls for high GPM flow rates and larger plumbing to accommodate all the jets needed. Since the distance to the target is less critical, moving or adjustable manifolds are unnecessary. Also, because the straight stream pierces the air rather than pushing it, parts are less likely to be blown around, thus reducing the need for special racking.

The high PSI necessary to operate fan-jet style parts washers requires high horsepower pump motors. Being under high pressure, the motors, pumps, and seals on these units are more likely to fail and need replacing. The high volume, low pressure design of the straight stream parts washer does not require large expensive motors and the low pressure ensures a long life on system components.

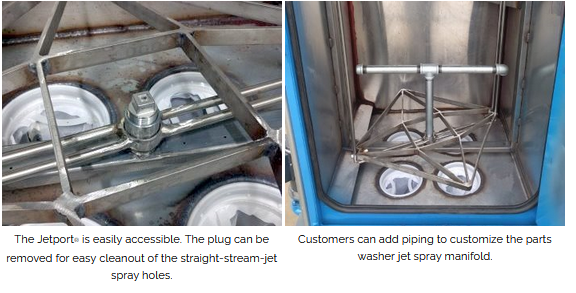

The plugging up and subsequent cleanout of the jets is another significant factor in the efficient operation of parts washers. In a fan-jet type washer, the loss of a single fan jet leaves a large unwashed area. The close spacing and a large number of straight stream jets minimize the effect of the loss of a jet. In addition, cleanout of straight stream jets is relatively easy. Simply use a piece of wire, push the obstruction back into the manifold, remove the manifold cleanout port, and turn on the pump. To unplug a fan-jet normally requires the jet to be unscrewed, cleaned, and reattached.

Easy Rack Fixturing System

The Easy Rack Parts Fixturing System allows the user to customize the racking/holding of their parts in virtually unlimited configurations. Easily field adaptable for individual needs, multiple turntables, baskets, and other fixtures can be added or modified to suit your cleaning needs.

Jetport®

The Jetport® is located on the spray manifold and can be used to flush out the spray manifold or to modify the spray pattern to meet your needs. Standard 1 inch plumbing can be added to provide additional cleaning power where needed or to clean the interior of cylinders, engine blocks, or other items.

Warranty

EMC through its Distributor warrants each new product sold by it to the initial user to be free of defects in material and workmanship for a period of one year from the date of sale of the equipment. FOB Los Angeles, CA.

EMC will provide, as an exclusive remedy, a new part or repaired part, at its election, in place of any part that is found, upon inspection, to be defective in material and workmanship during the period described above. Purchaser must present proof of purchase (and purchase date) at the time of exercising this warranty.

This warranty does not apply to failures occurring as a result of incompatibility of fluid type to material of construction, abuse, misuse, negligent repairs, corrosion, normal wear and tear, and alteration or modifications made to the product without express written consent of EMC or failure to follow the recommended operating practices and maintenance procedures as provided in the product`s operating and maintenance publications.

The warranty provided herein does not apply to equipment sold hereunder but manufactured by others as they are warranted by their respective manufacturers directly to the user, such as electric motors.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, AND THERE ARE NO WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF LIABILITY

The remedies of the user set forth under the provisions of warranty outlined above are exclusive and total liability of EMC or its Distributor with respect to this sale or the equipment and service furnished hereunder, in connection with the performance or breach thereof, or from the sale, delivery installation, or repair or technical direction covered by or furnished under this sale, whether based on contract, warranty, negligence, indemnity, strict liability or otherwise shall not exceed the purchase price of the unit of equipment upon which such liability is based.

EMC shall in no event be liable to the user, any successor in interest or any beneficiary or assignee relating to this sale for any consequential, incidental, indirect, special or punitive damages arising out of this sale or any breach thereof, or any defects in, or failure of, or malfunction of the equipment whether based upon loss of use, lost profits or revenue, interest, lost goodwill, work stoppage, impairment of other goods, loss by reason of shutdown or non-operation, increased expenses of operation, cost of purchase of replacement power or claims of user or customers of the user for service interruption whether or not such loss or damage is based on contract, warranty, negligence, indemnity, strict liability or otherwise.

NOTE: Equipment Manufacturing Company (EMC) makes no warranty concerning the applicability of the Water Eater to evaporate any particular fluid. Final determination of appropriateness of this equipment for any usage is that of the customer.