- Home

- Companies

- Water and Wastewater

- Water Treatment

- Toro Equipment S.L.

Toro Equipment - Model PAP-3C INOX -Automatic Polyelectrolyte Preparation Plant

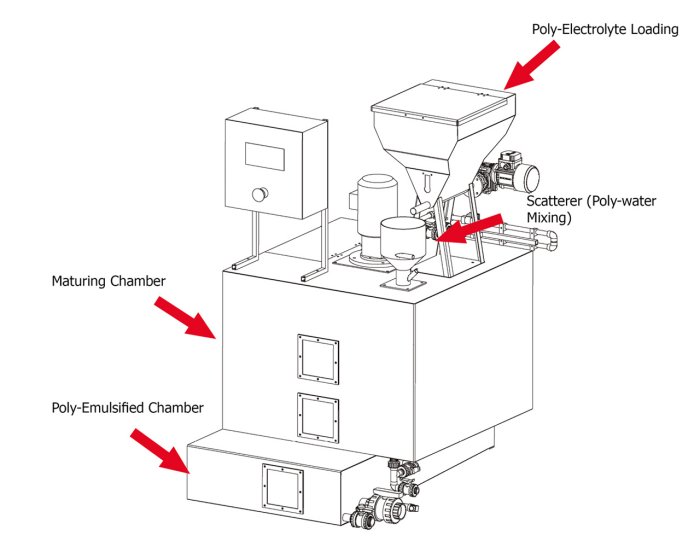

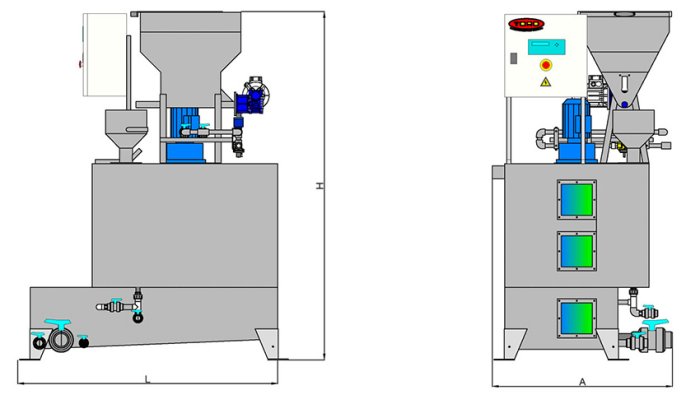

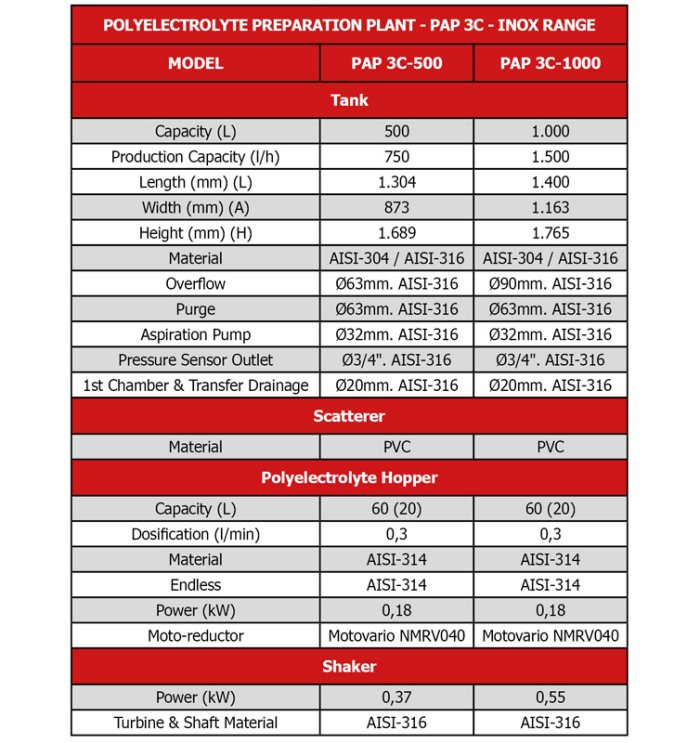

It consists of three chambers, one for mixing, one for maturation and one for collecting the mature polyelectrolyte at the optimum point for use. The retention time of each chamber is 30 minutes. It includes an anti-condensation nozzle for the exit of the polyelectrolyte. It has a double helix to favour mixing. It can work with both powdered and emulsified polyelectrolyte. Continuous operation. Made of stainless steel.

It facilitates sludge treatment making sludge dewatering more cost effective and efficient.

Toro Equipment’s Sludge Conditioning Tank (TAF) is a vertical cylindrical GRP tank that allows the chemical conditioning of sludge, facilitating filtration or decantation processes.

Once the sludge has been pre-treated, it can be dewatered by means of a Filter Press.

- It has an agitator for mixing the sludge. Its operation is controlled from the plant control panel.

- It has a visibility strip for visual control of the sludge level.

- It is equipped with a level system that indicates the height of the sludge in the tank.

The installation of the Automatic Polyelectrolyte Plant is indispensable for dosing chemicals in wastewater treatment. They are used for flocculation of solid particles in all types of wastewater, industrial and urban wastewater.

These plants allow the preparation (mixing with water), maturation and dosing of the polyelectrolyte in an automatic and simple way.

Advantages of the automatic polyelectrolyte plant:

- The supply pressure can be regulated as required by means of a solenoid control valve and pressure reducer with pressure gauge in the water circuit.

- It is corrosion resistant.

- It has automatic start and stop control of the agitator, the polyelectrolyte feeder and the water inlet.

- It is designed to prevent the formation of lumps.

- PAP 3-C is composed of three chambers: mixing, maturation and the third one that picks the mature polyelectrolyte in optimal condition for dosing.

- Each chamber has 30 minutes retention time.

- PAP 3-C is armed with a flow-meter-inlet.

- It is equipped with an anticondensation duct.

- It has double helix to favour the polyelectrolyte mixture.

- Displays allows you to see the product in each phase.

- PAP-3C includes alarms for shortage of product, water and pressure.

- The hopper is 60l capacity.

- The arrangement allows to add polyelectrolyte without stairs.

- You can make a bypass in the chambers to spend the entire product during the stops.

- First filling function.

- It boosts the fast disolution of the polyelectrolyte, avoiding lump formation.

- Ideal design for containerized plants, it takes up less space.

- PAP-3C counts with electrical panel, with 4” touch screen and automaton S7-1212, it has calibration system of raw material and concentration control system of finished product.

Completely standardised and ready to assemble.

Manufactured in GRP. This material makes them more resistant to corrosion and more durable than conventional ones.

These wall display cases can be installed both indoors and outdoors.

Materials details:

- Body made of GRP (glass fibre reinforced polyester).

- Removable walls to facilitate pump maintenance tasks.

- Polycarbonate front screen.

- PEHD (High Density Polyethylene) lower tray.

- Protection with anti moisture absorbent bags in engines areas.

- Black film wrapping for UV protectioning.

- Equipment placement on a pallet for easy transportation.