- Home

- Companies

- QED Environmental Systems, Inc

- Products

- AutoPump - Model AP4+ - Landfill and ...

AutoPump - Model AP4+ -Landfill and Remediation Pumping

The AP4+ was made easier to clean by using 3 bolts to attach the pump inlet and open up the pump. This is easier than having to rotate the inlet multiple turns to unthread it from the center tube inside the pump, especially under field conditions of silt, deposits and coatings. Removing the inlet is also aided by the new, precision ID pump casing, ensuring a more controlled fit. The new pump casing’s smoother internal surface has the added benefit of reducing the rate of buildup of solids and coatings inside in some cases. The Easy Fittings make it a snap to remove the tubing from the pump without cutting, and the float is now easily removed by pulling a clip.

The new AP4+ features upgraded materials for many parts to further extend the service life of the pump and to broaden the range of conditions each model can be used in. All nonmetallic internal parts are now made of PVDF*; this is a high-grade engineering plastic with higher strength at elevated temperatures and extremely broad chemical resistance, including to acidic and oxidizing cleaning agents sometimes used for pump maintenance. All stainless steel parts have been upgraded to 304 grade or higher for improved corrosion resistance.

The new and improved warranty, a straight 5-year warranty with no pro-rating, is proof of the AP4+`s successful history and continued improvements.

Of course, the new AP4+ is compatible with the autopump Family of Accessories, including:

- Sheathed nylon pump tubing sets for maximum chemical resistance, reduced weight, less tangling and easier handling, another innovation lead by QED.

- QED’s Easy Fittings for affordable, quick connection and removal of the pump from its tubing set, built to function easily even under high solids well conditions. These are now available pre-installed to pump and tubing so pump system installation just snaps together!

- QED’s Easy Bolts for rapid access to flanged wellheads.

- The industry’s widest range of wellhead completions to match your site so that pump installation goes smoothly. Custom options are available to fit your specific wellhead requirements.

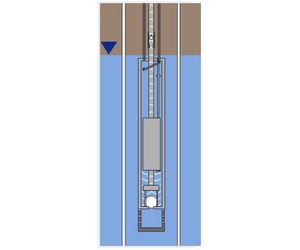

AutoPumps are air-powered positive displacement pumps that require no surface timer-based controllers, bubblers or sensors in the well to operate. The pump is activated by an internal float in response to the natural well recharge. Because the AutoPumps fill by gravity and discharge by air displacement, no emulsification is created during its operation.

Fill Cycle

- The fluid pushes the inlet check-valve open and fluid enters the pump.

- As the fluid level rises, air is expelled through the exhaust air valve and the internal float rises to the top of its stroke.

- In this upper position, the float triggers a lever assembly, which closes the air exhaust valve and opens the air inlet allowing air to enter and pressurize the pump.

Discharge Cycle

- With the air inlet open, air pressure builds up within the pump body. This causes the fluid inlet check-valve to close and forces the fluid to be displaced up and out of the fluid outlet.

- As the fluid level falls, the float moves downward to the bottom of its stroke.

- In this lower position, the float triggers the lever assembly to close the air supply and open the air exhaust valve. And a new cycle begins.