- Home

- Companies

- Mokveld Valves BV

- Products

- Axial Check Valve

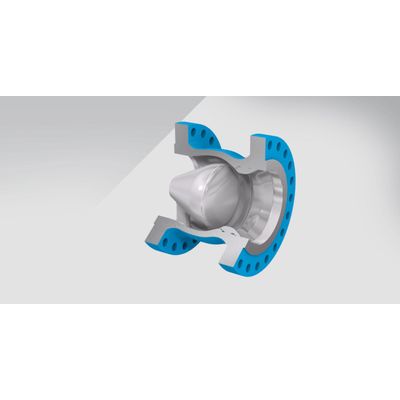

Axial Check Valve

An axial check valve is the preferred solution for critical non-return applications such as the protection of rotating equipment and systems where low pressure loss, stable operation and dynamic behaviour are essential.

- Type designation: Check or non-return valve

- Model: TKZ - Y

- Scope: Sizes 2" - 76", Rating class ASME 150 - 2500 or API 3000 - 10000, Higher pressure ratings on request

- In preference to:

- Swing check valve (including controlled closure devices)

- Dual-plate check valve

- Piston check valve

- Typical applications:

- Critical compressor / pump protection

- Severe duty

- Low pressure drop

Axial flow

Streamlined flow path through full-port expanded body avoids turbulence and prevents erosion and vibration. Process downtime and maintenance costs are eliminated.

Low pressure drop

The full opening flow passage and high-pressure recovery of the venturi-shaped body result in very low pressure loss: reduced operating cost of pumps and compressors.

Easy opening

The low static pressure in the throat area is applied behind the disc and creates a pressure differential over the disc, resulting in easy opening.

Stability

Extremely stable during operation. The axial check valve responds smoothly to changes in flow and remains stable whit it is supposed to be.

Non-slam operation

The spring-assisted design ensures ultra-fast closing without backflow and pressure surges, in critical applications such as multi-pump systems.

Tight shut-off

Tight shut-off is obtained by means of metal-to-metal sealing. This sealing is not affected by erosive flow.

Maintenance free

Internal construction is based on the application of sound basic mechanical engineering principles. Consequently, the axial check valve does not require any maintenance.

Special features

-

Custom-designed valve to meet the clients specific process conditions.

-

Fire-safe, cryogenic and sub-sea design.