AXIS - Model GB812 -Guided Boring System

When it comes to installing sewer and water lines, your main goals are on-grade accuracy and exceptional productivity. The AXIS GB812 Guided Boring System from Vermeer delivers both. The closed-circuit camera built into the drill head allows the operator to constantly monitor line and grade, while the vacuum excavation method removes spoils efficiently without the need for manual labor. Plus, the unit’s modular design can be configured in a number of ways to match jobsite constraints.

- Choose your pipe because the AXIS system has the ability to push or pull in a variety of product pipes.

- Maintain clean pits using the vacuum excavation unit, which handles spoil within the launch pit without suspending drilling operations.

- Select your tooling with a variety of cutter-face tooling options to match varying ground conditions.

- Minimize restoration costs because only two pits are needed, which can later serve as manhole locations.

- See your Vermeer dealer for comprehensive service and genuine Vermeer replacement parts.

A growing number of water and sewer projects are required to be placed precisely on-grade. This work is often viewed to be tedious, labor-intensive and expensive using traditional installation methods. Some of the current trenchless methods are designed to achieve the extreme accuracy necessary for this kind of work; however, they lack the productivity needed to compete with the open-cut method.

Now underground contractors have a new tool in the effort to replace and expand the crumbling sewer and water infrastructure.

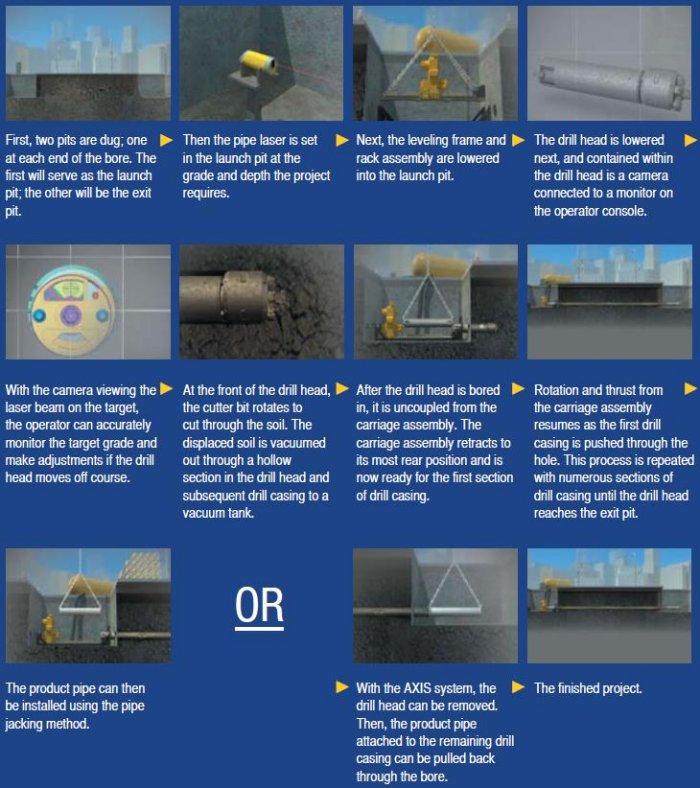

The Vermeer AXIS™ guided boring system is a pit-launched trenchless installation method designed to achieve pinpoint, on-grade accuracy while eliminating some of the difficult steps associated with other installation techniques. A wide range of product pipe, sizing specifications and other jobsite requirements can be met with the versatile capabilities of the AXIS system.

Precise On-grade Drilling — A closed-circuit camera integrated into the drill head allows the operator to constantly monitor the process on a screen integrated into the controls console. The operator can make corrective steering adjustments to the drill head if needed to maintain line and grade. This combination of user-friendly technology allows the AXIS system to achieve the precision tolerances demanded by on-grade installation.

Clean pits — The vacuum excavation method utilized by the AXIS guided boring system eliminates the need to suspend drilling operations to manually handle spoil within the launch pit. Eliminating manual interface with excavated material can also provide a cleaner pit environment.

Installed Product Pipe Compatibility — The AXIS system has the ability to install both rigidly constructed, as well as fusible and restrained joint product pipe. The system is compatible with a range of pipe options, including PVC, clay, steel, ductile iron and HDPE. This versatility gives project owners more product pipe options based on factors such as costs, traditional preference and matching with existing infrastructure.

Non -structural pits — The AXIS guided boring system requires a relatively low amount of thrust / pullback force to efficiently bore as compared to other pit-launched trenchless methods. It doesn’t require the construction of a structural backstop or shaft within the launch pit helping to reduce project costs.

Modular design — With a flexible, modular design the AXIS system can be configured in a number of ways for jobsite footprint and transport considerations. It can accommodate customer preference with a number of truck and trailer setup options. This allows the system’s footprint to be limited to one lane of a street, thus minimizing traffic disturbance.

Production time — A variety of cutter face options are available to help boost drilling performance in varying ground conditions, including rock, shale / reef, clay and sand / mud / silt. If ground conditions require a cutter face tooling change during the bore, the drill casing and head can easily be backed out to select a more efficient cutter style.

Restoration costs — The AXIS guided boring system is designed to help minimize restoration costs compared to other methods. It requires surface excavation for two pits that can serve as the manhole locations, saving additional excavation time and resources. When compared with open cut, the AXIS system significantly decreases surface restoration costs.

EXCAVATED material REMOVAL — The vacuum excavation method helps to maintain a clean and compact site. Gone are the piles of spoil and the multiple trucks and loaders often required with other methods. Once the spoil is contained in the vacuum tank it can be transported to a separate site for disposal.

Safety — Compared to other sewer and water installation methods, the AXIS system requires only two pits and worker movement in and out of those pits is minimal. The AXIS system also features a patented remote lockout, strike alert and falling object protective structure (FOPS) for jobsite safety.

Dealer Network — Our network of independent, authorized dealers spans the globe and stands ready to assist you in better understanding the sewer and water market, but more importantly we stand by you every step of the way. From market expertise to selecting the right solution to jobsite training, our dealers are second to none and ready to help no matter where you are located around the world. Making sure they not only meet your needs, but exceed your expectations.