Ayrox

Most popular related searches

- increases the aesthetic and comfort values of top-shaded windscreens

- gives savings of 15-25 % with top-shaded PVB and 10 % with uniformly coloured PVB

Application

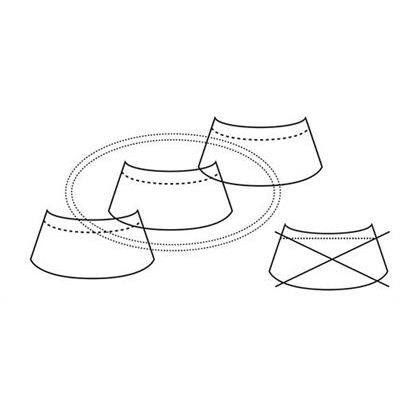

Clear, tinted and top-shaded PVB can be processed. The line is well adapted for shaping both refrigerated and interleaved PVB. It is equipped with automatic interleaf rolling-out system.

The machinery can be used for :

- shaping top-shaded or uniformly coloured PVB with the minimum radius of 2100 mm

- stretching PVB to optimal thickness within quality requirements

- cutting clear and tinted interlayer at any desired angle between 0-25º

- shaping, stretching and cutting machines can also be operated individually

Production Capacity

- Shaping: The operating speed for shaper SMF 3: 3m/min, for SMF 6: 6m/min

- Cutting: Max. speed for FCM cutter is 6 m/min; When used as a part of the line the cutting machine is synchronised with the shaper or relaxation module.

Savings

In optimal use, the line

- minimises waste

- offers considerable savings by more efficient use of PVB

- decreases stock items

LAY-OUT AND AMBIENT CONDITIONS

The equipment should be installed in a dust-free area, preferably in clean room conditions.

The whole line, SMF+REL+FCM should be positioned in a room with a temperature of 20 ±2ºC and RH of 25-30 %.

According to the user’s needs :

- separate cutting with drive, operation width 1250 – 1700 mm

- antistatic treatment of PVB

- manual stackers

- humidity measurement