Azeus - AZSPLM300 Portable Pellet Mill

This portable electric feed pellet mill can be used, together with hammer mill, feed blender, conveyor and pellets packing machine, to make animal feed pellets for chicken, cattle, duck, cow, sheep, pig, etc. on a small scale. By the way, this pellet mill also can be used to make wood pellets from wood wastes. If you want to start a small feed pellet plant or wood pellet plant, AZSPLM300 is a right choice for you to earn money with less investment. For more details, please contact info@buypelletmill.com

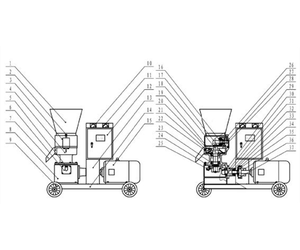

1.Upper hopper

2.Adjusting screw

3.Upper shell

4.Lower shell

5.Dipstick

6.Checking screen

7.Discharge gate

8.Gear box

9.Base wheel

10.Current meter

11.Voltmeter

12.Electric control box

13.Electric control box support

14.base

15.Motor

1. It has simple structure and it can be easily cleaned and maintained.

2. It provides small capacity at lower price; it is in small size and light weight; it is a best choice for pellet production on a small scale.

3. This pellet mill is easy to operate--just 1 or 2 workers can operate the pellet machine.

4. Operators are able to have a view of the chamber, so it is easy to find problems during pelleting.

5. Spare parts, i.e. rollers and die are easy to change.

6. It is also a right choice for wood pellet producers and animal bedding pellet producers.

A. Location

1. Place the pellet machine at a safe and dry place.

2. Do not operate the pellet mill at a temperature of below 10 degree celsius.

3. Make sure all bolts and nuts are securely tightened before operation.

B. Test Run

Before starting producing pellets, it is important to polish the die to make it smooth. To do this, you need to prepare 5kg flour, 5kg fine sand and 1.5 liter vegetable oil, and then mix the ingredients into a bucket. Next, start the pellet machine, and then put a proper amount of mixed materials into the mill and let them run through the die hole. You should do this repeatedly for 40-60 minutes.

C. Before first run, adopt grease to lubricate all bearings. The operator needs to do this once at lease every 10 hours.

D. Set the pressure for the roller wheels. To do this, just drag the die and find whether it can rotate under the rollers. The gap between rollers and die should be controlled within 0.1-0.3mm.