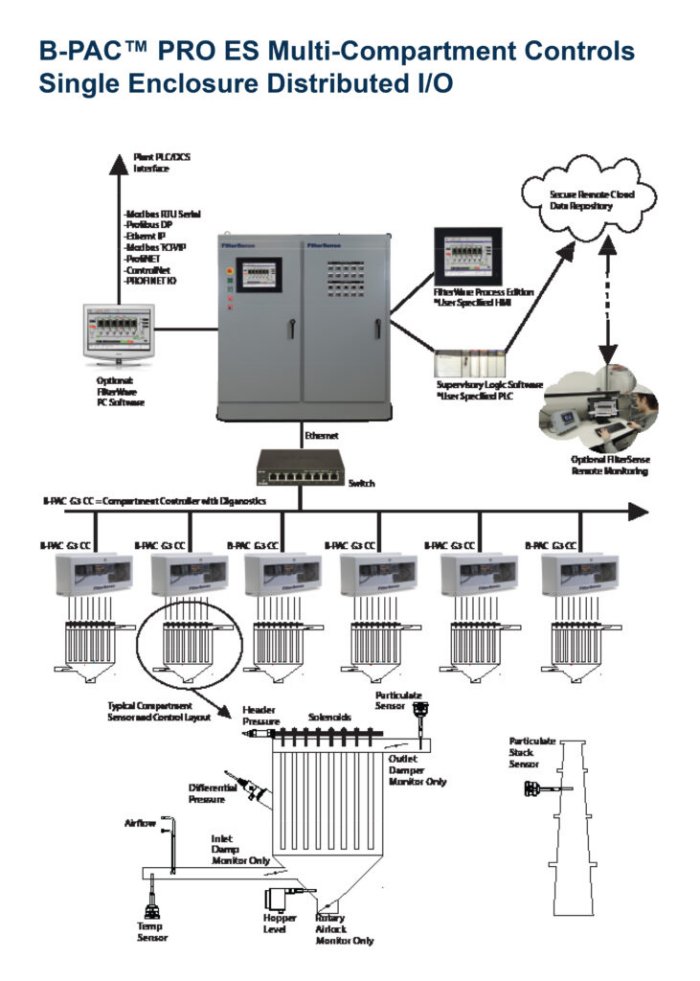

B-PAC - Model PRO ES -Advanced Baghouse Performance Analysis & Control

For full on-site control and monitoring of filtration processes, the B-PAC™ PRO ES provides the complete solution for large-scale custom designed applications. Utilizing an overarching PLC for universal integration allows for complete command of all process variables for the maximum increase of operational efficiency. Custom Designed for your application utilizing both DynaCHARGE™ Technology and B-PAC ™ Controls. This is an engineered system that provides maximum achievable control over particulate emissions to comply with EPA mass emission limits while simultaneously providing process optimization and total filter performance management.

B-PACs™ Require a Particulate Sensor, Differential Pressure, and Header Pressure inputs. Please see available sensors below or Contact Us for guidance:

- Real-time detection and location of failed solenoids and pulse diaphragms

- Detect and locate filter leaks

- Integrated compressed air management

- Highly configurable cleaning parameters, row sequencing, and patterned pulsing

- HMI/SCADA, record keeping, reporting, and remote access via FilterWARE™

For multi-compartment and large single-compartment baghouses

Technical Data

- Compartments: No Limit

- Differential Pressure Control: ± 0.1 InWC – Overall or Per Compartment

- Operating Temperature: -40 °F to 158 °F (-40 °C to 70 °C)

- Hazardous Area: Class I Div. I (Zone 0/20)

- Power: 110-220VAC, 208VAC, 480 VAC

- Compartments Solenoids: No Limit

- Compartment Dampers (& Other Small Motor Controls): No Limit

- Compartment Header Tanks: No Limit

- Compartment Particulate: No Limit

- Auxiliary Sensors: Differential Pressure, Particulate, Header, Air Flow, Fan Amps, Hop- per Level, Temperature