- Home

- Companies

- SPX Technologies

- Products

- Cincinnati Fan - Model HDBC - Backward ...

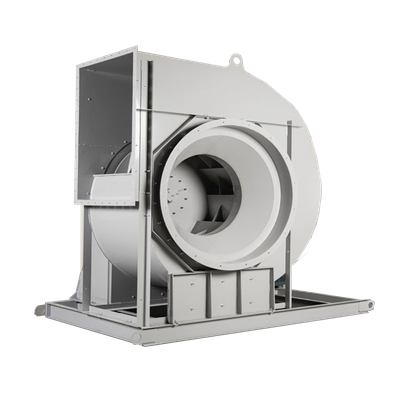

Cincinnati Fan - Model HDBC -Backward Curved Fan

Cincinnati Fan offers the Model HDBC Backward Curved Fan, engineered for efficient air delivery across various applications. This fan model is available in 18 different sizes, adhering to the AMCA Class V construction standards. It is suitable for high-volume air movement, with one-wheel design options and width variations from 50% to 100% customization, catering to specific performance requirements. Additionally, it comes with four belt-driven configurations, boasting both all-aluminum and stainless steel material choices. The Model HDBC is certified for AMCA A, B, or C spark resistance, making it apt for demanding environments. Its performance attributes include the capacity to handle up to 270,000 CFM and withstand air stream temperatures up to 200°F, with an optional high-temperature configuration tolerating up to 750°F. For applications needing greater capacity, complementary models from Daniels Fans, such as the BI Industrial Fan, are recommended for tailored airflow, pressure, and temperature demands.

Cincinnati Fan manufactures 18 sizes of the Model HDBC Backward Curved Fan in AMCA Class V construction. The Model HDBC is an excellent choice for efficient delivery of high air volumes.

All models are available with one wheel design and in multiple widths from 50% to 100%, to deliver the exact performance you need with a direct driven fan. Four belt driven arrangements are also available. All aluminum or stainless steel construction is available.

This fan is available in AMCA A, B, or C spark resistant construction.

PERFORMANCE RANGE:

- Capacities up to 270,000 CFM and 34″ SPWG

- Standard construction, air stream temperatures up to 200°F (93°C)

- Optional high-temperature construction, temperatures up to 750°F (398°C)

- All models available with housing and wheel widths from 50% to 100%, in 5% increments, to deliver the performance you need with a direct driven blower.

- Continuous welded housings, instead of lock seams, eliminate air leakage.

- Heavy gauge steel bases, with internal bracing, maximize rigidity and promote long equipment life.

- Blower housings can be rotated in 45° increments, on sizes 300 and smaller, to provide increased configuration flexibility in the field.

- Removable inlet & drive side plates allow for removal of blower wheel or motor, or shaft and bearings on belt driven models, without disconnecting inlet or discharge connections.

- Inlet side support assures a minimal vibration housing.

- All fans receive a mechanical run test to ensure proper balance and alignment before shipping.

- Belt driven models include heavy duty, grease lubricated, self-aligning, cast iron, and pillow block bearings selected for optimal performance.

- Fan shaft on belt driven models is turned, ground, and polished and receives a high-quality rust preventative coating before shipment.

- Arrangement 8 units come standard with shaft/coupling guards

- Arrangement 9 and 9CB units come standard with belt guards.

- Arrangement 10 units come with weather cover.

- All models are also available in aluminum or all stainless steel construction.

- Multiple Wheel Selections: Each size and class are available in multiple widths from 50% to 100%, in 5% increments, to deliver the exact performance you need with a direct driven blower. Complete design flexibility.

- Rugged Construction: Housings are heavy gauge steel and are continuously welded to prevent leakage. Fan bases are 7 and 10-gauge steel with internal bracing to prevent pulsation at all conditions. Less field problems.

- Rotatable Housings: Most models have housings that can be rotated in 45° increments in the field. Allows for field conversion without replacing the blower.

- Ease of Maintenance: Replacing a wheel, motor, or shaft and bearings on belt driven models, is easily accomplished without disturbing the inlet and/or discharge connections. Minimizes extended downtime.

- Quality Components: All belt driven models have self-aligning, cast iron, grease lubricated, pillow block bearings sized for a minimum 150,000 hours average life. All fan shafts are turned, ground, and polished and are coated with a high-quality rust preventative before shipment. Long dependable service.

- Material conveying

- Cooling

- General ventilation

- Dust collection

- Combustion air

- Oven and drying systems