IPEC

Most popular related searches

thermal decomposition

oil contaminated soil

thermal decomposition plant

oil sludge

sludge oil

oil contamination

hydrocarbons waste

soil reclamation

drilling mud

water distillation

100 kg/h

processing speed

processing speed

2

qty of cycles of processing per day

qty of cycles of processing per day

5 kW

tension

tension

380 volt

power consumption

power consumption

Usage of the product derived from hydrocarbon-based raw materials:

- Dry residue is used as asphalt filler, in soil reclamation, construction or in production of coal bricks

- Heat of the process is recovered and used locally*

- Pyrolysis oil is used as:

- low grade fuel in boiler units

- fuel of higher quality, such as diesel**

- Syngas is used for the heating in the process

Usage of the product derived from brine-based raw materials:

- Distilled water is used as:

- drilling solution preparation

- drinking water ***

- Dry residue is used as asphalt filler and concrete additives

- Heat of the process is recovered and used locally*

- * With an optional heat-exchanger (recuperator)

- ** With an optional rectification column

- *** With an optional purification and mineralization systems

INTENDED USE: Pyrolytic thermal decomposition of hydrocarbon waste with the recovery of pyrolysis gas, liquid fuel, and dry residue (carbon black).

WASTE TYPES: solid and liquid non-halogenous organic waste such as:

- Plastics, tires, rubber, polypropylenes,

- Oil sludge, oil-contaminated soils, drilling sludge and coal,

- Waste oils, tar, bitumen, kerosene, any type of solvents,

- Fuel oil residue, lubricating and heavy oils.

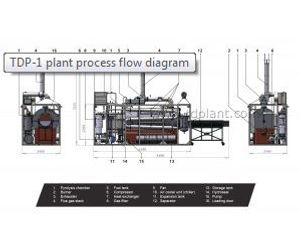

- Feedstock is loading into pyrolysis reactor through wide loading door, where combined gas-liquid burner without oxygen access heats it and the process of thermal decomposition starts.

- Fuel is self-fed to the burner. The boiler fuel or diesel oil is used for the system’s start up only. After process stabilizing the burner is switched to the pyrolytic gas.

- Vapour and gas mix from pyrolysis chamber is fed to the condensation system through gas filter.

- Air is fanned to the filter jacket for cooling the mixture. Condensate is drained through bottom valve to the drum.

- The further cooling of the mixture is carried out in the heat exchanger by recirculation.

- From heat exchanger the product is fed to the gas-liquid separator where flows are separated.

- PYROLYSIS OIL is directed to the storage tank;

- SYNGAS is directed to the burner through hydroseal to satisfy system’s energy needs.

- SOLID RESIDUE is discharged by tray through wide loading door.