Gianni Mori Engineering S.r.l. (GME)

- Home

- Companies

- Gianni Mori Engineering S.r.l. (GME)

- Products

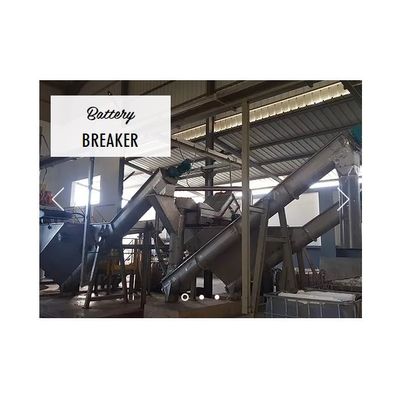

- GME - Battery Breaker Recycling Plant

GME - Battery Breaker Recycling Plant

Battery recycling breaking process with low cost recovery of valuable lead and plastic / de-sulfuration of lead paste.

Most popular related searches

battery breaking

battery recycling system

recycling plant

battery recycling

lead battery recycling system

lead battery recycling

filter press cleaning

lead battery

lead recycling plant

hammer mill

- Drained lead acid recovery and collection

- Breaking of the battery scraps in Hammer mill

- Separation of high purity battery lead paste

- Recovery of battery lead paste dewatered with filter press

- Clean Grids & Poles recovering

- Recovery of Polypropylene with additional option of grinding

- Recovery of PE (Polythene)

- Process to remove sulfur crayon lead (de-sulfation)

- Battery Lead Acid drainage filtered with the possibility of re-sell

- Grids & Poles metallic yield minimum purity 98.5%

- Battery Lead paste very low contamination from lead metal and plastics, with moisture < 10%, residual sulfur < 0,4% (only for de-sulfuration treatment)

- Polypropylene (chips) minimum purity 99.5%, size 70/100 mm or 15mm after grinding

- PE (Polythene) to be sent to landfill or with the possibility of combustion in rotary furnace

- 98.5% purity minimum

- moisture <10% residual sulfur <0.4%

- 99.5% purity minimum