- Home

- Companies

- Bergmann, Heinz, e.Kfm.- Machines for ...

- Products

- Bergmann - Model APB 607 - Alpha Pack ...

Bergmann - Model APB 607 -Alpha Pack Bin for Roll-Off Skip Loaders

Special charateristic of the BERGMANN Alpha-Pack-Bins are very high compaction results - due to the linear position of the compaction cylinder and the continuous filling in a large and easy-to-feed loading aperture, even if the container is currently in the compaction mode. Thus, very high compaction results are realised. Through the huge and easy-to-feed loading aperture, the container can be continuously filled, even if the container is currently in the compaction mode.

A standard feature of the Alpha-Pack-Bins is the automatic self-cleaning of the patented BERGMANN throw-over blade system. No manual, difficult and unhygienic cleaning of the compacting piston is required.

BERGMANN Alpha-Pack-Bins of the series 607 are available for roll-off skip loaders and have a low operating noise level. They have a well-developed design and technology and convince because of their low-maintenance operation.

- Mobile waste press container with throw-over blade system for cardboard boxes, paper and foils

- Roll-off skip loader version

- Electrohydraulic drive

- Modular structure for flexible application and rigging possibilities

- Special designs per customer’s request

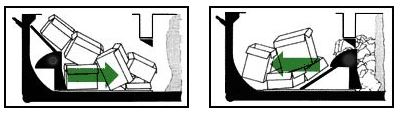

- Illustration of the self-cleaning pendulum blade with throw-over blade system in front position. During the compactor stroke and the following return stroke, the entire filling area is available for continuous filling.

- Illustration of the self-cleaning pendulum blade with throw-over blade system in extreme rear position. Thanks to the throw-over blade system, the material thrown in during the preceding compactor stroke is thrown in front of the compacting piston.

- BERGMANN`own development with patented throw-over blade system and many years of experience

- Ideal for compacting re-usable material like paper, cardboard, foils, etc.

- The APB does not have cleaning flaps because it is self-cleaning due to the patented throw-over blade system -> saving personel costs for the cleaning. Unhygienic cleaning activities are not necessary. Huge loading aperture (approx. 1,700 x 1,800 mm)

- Filling edge = filling area The waste need not be thrown above the cylinder area

- The machine can be continuously feeded thanks to the patented BERGMANN throw-over blade system even if the compacting piston is in the return stroke.

- Highest compaction due to the typically linear arrangement of the compaction cylinders made by BERGMANN is proven. Thus, the waste is compacted to a minimum of the original volume

- Comfortable operation by clearly arranged push buttons

- Trouble-free emptying through sliding plates. (no point)

- Negligible operating noise

- Reduction of disposal costs of up to 75%

- Long service life of the machine through rare emptying = high availability on site

- Drastic savings by reducing the number of disposal journeys to a minimum

- Lowering of personnel costs for waste handling

- Minimising the utility space for waste storage. Thus, saving on storage costs and storage areas for conventional containers

- Can easily be expanded due to its modular structure. Thereby you have a simple customisation to various locations

- The highest quality standard for years

- Well-developed design and technology on the basis of many years of experience

- High, fast and available for spare parts for many years, guaranteed for 15 years!

- Worldwide service network

- Huge loading aperture (approx. 1,700 x 1,800 mm) with a volume of 4.1 m³

- Enormously high processing capacity of 2.00 m³ per working stroke

- High compaction force of 345 kN with APB 607 SN 20

- Press plate guiding system with 100% compaction force over the full stroke length

- High filling weights of, on the average up to 4.5 tons cardboard boxes in the APB 607 SN 20 and more

- Compactor stroke in only 35 seconds

- Durable, purely hydraulic drive unit with maintenance-free central hydraulic block

- Compaction chamber and press plate constructed from extremely high steel strengths. Bottom of the loading aperture made of high-quality and wear-resistant steel

- Front and rear pick-up hook are variable in height for adjustment to all standard roll-off skip loaders

- Laterally fastened door with 3 central locks via easy-to-serve ratchet catch

- Pendulum claws on the break edge and the large immersion depth of the compacting piston avoid that the waste streams back

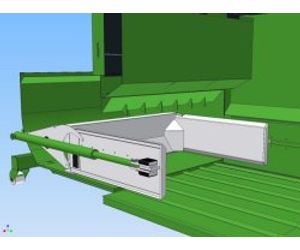

- Ease of maintenance: easily accessible hydraulic power pack above the compaction chamber can be reached via wing doors

- Great stability with economic net weight

- Machine TÜV/GS and CE-certified

- Skirting protection of the control elements for protection against damages

- Bin is continously welded

- Circulation of the material due to special circulation edges at the discharge opening results in a high volume utilisation of the container

- Completely “Made in Germany” by qualified and experienced staff

- Pick-up-system, pluggable and turnable in the front, thus fast and easy adjustment of the pick-up height by means of bolts on various unwinder types

- Differential circuit for quick stroke periods

- Self-cleaning throw-over blade

- Drip tray with drain valve

- Central storm-water runoff

- Autotimer

- Oil level indicator and oil level monitoring

- Overload protection

- Working hour counter

- Unproblematic retrofitting with a lid covering the loading aperture

- Hydraulically controlled and, thus, durable reversing valve

- 2 rear rollers

- Screwable pick-up-system in the back, thus pick-up height of 1,450 mm and 1,570 mm possible

- 2 front rollers

- ¾ full and/or 100% full signal

- Increased lateral walls in various designs

- Full signal via GSM Module to you or disposer

- Double hydraulic pump for even quicker stroke periods

- Manually or hydraulically operated lid covering the loading aperture in the back or fastened laterally (protects against filling by unauthorised persons and the penetration of rain water)

- Rubber seal of the lid (reduces odors and provides watertightness)

- Lift-tipping-device, integrated for pivoting and/or comb lifting system (lifts the waste bin and tips the contents into the compactor)

- Remote control via cables

- Photo electric cell in the filler area (automatic start of the machine)

- Fire fighting point

- Connection for draining

- Flap covering the control panel, lockable against vandalism

- … and many more

- … ask for special versions

Everywhere, where dry re-usable material accumulates, as in:

- Supermarkets

- Trade

- Industry

- Printing houses