Bergmann, Heinz, e.Kfm.- Machines for Waste Management

- Home

- Companies

- Bergmann, Heinz, e.Kfm.- Machines for ...

- Products

- Bergmann - Model MPB 405 - Mobile Pack ...

Bergmann - Model MPB 405 -Mobile Pack Bin for Skip-Lift Vehicles

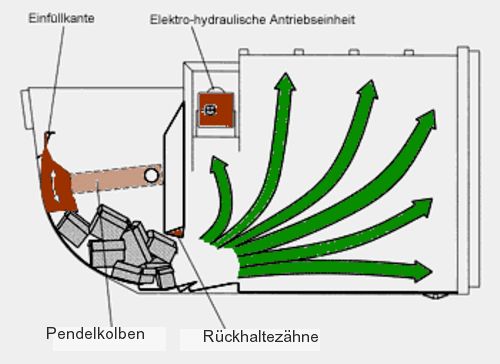

The Bergmann pendulum blade technology of the Mobile-Pack-Bins makes an extremely high compaction of garbage possible in a compaction container that can be made waterproof. Particular attributes of the Mobile-Pack-Bins invented and patented 35 years ago by BERGMANN are the hygienic self-cleaning, the easy emptying and the continuous filling. Due to the well-developped technology and design, Bergmann Mobile-Pack-Bins of the 405 series for skip-lift vehicles have a low operating noise, are durable and particularly low maintenance.

Most popular related searches

mobile bin

compact wet waste

skip loader

oil level monitoring

wet waste

rainwater

waste container

level monitoring

level indicator

hydraulic cylinder

- Mobile-Pack-Bin for waste and wet waste

- Roll-off skip loader version, space-saving

- Electrohydraulic drive

- Modular structure for flexible application and rigging possibilities

- Special designs per customer’s request

- Illustration of the self-cleaning pendulum blade in rear position

- During the compactor stroke, the entire filling area is available for continuous filling.

- In the return stroke, it can be fed again. The pendulum blade passes under the material and positions the waste ready for the next cycle.

- Illustration of the pendulum blade at the end of the compactor stroke. The garbage was pushed under the break edge into the container.

- THE original with more than 35 years of experience. Invented and developed by BERGMANN

- Well-developed design and technology on the basis of many years of experience

- Ideal for compacting wet waste and residual waste

- Huge loading aperture

- Can be continuously fed with garbage

- Reduction of disposal costs of up to 75%

- Long service life = high availability

- Extremely high compaction depending upon type of garbage to a fraction of the original volume = high filling weights of, on the average, 3 tons of residual waste in the MPB 405 SN 8 and more

- Reduction of the number of emptying journeys to a minimum = drastic savings by fewer disposal journeys

- Comfortable operation by clearly arranged push buttons

- Trouble-free emptying of the container by lateral convexity

- Low corrosion because the hydraulic cylinders have no contact with the waste

- Hygienic self-cleaning (cleaning operation under and behind the compacting piston can be dispensed with)

- Negligible operating noise

- Can easily be expanded due to its modular structure; therefore simple adjustment to different locations

- Lowering of personnel costs for waste handling

- Minimisation of the utility space, thus saving the storage costs of convention containers

- The highest quality standard for more than 35 years

- High, fast and available for spare parts for many years, guaranteed for 15 years!

- Worldwide service network

- Huge loading aperture (approx. 1400 x 1,000 mm)

- Enormously high processing capacity of 0.65 m3 per working stroke

- Lateral conic container for trouble-free emptying

- High compaction force, 246 kN with MPB 405 SN 12

- compactor stroke in only 14 seconds

- Serially adjustable pick-up pistons for the chains of various lift tipper manufacturers

- Also available as a roll-off skip loader version

- Durable hydraulic drive unit with maintenance-free central hydraulic block

- Compaction chamber and press plate constructed from extremely high steel strengths

- Solid pendulum discharge door, triple hinged

- Special lock via hexagon socket assures an unsurpassed tightness

- Pendulum claws on the break edge and the large immersion depth of the compacting piston avoid that the waste streams back

- Easily accessible hydraulic power pack above the compaction chamber facilitates service operations

- Great stability with economic net weight

- Machine TÜV/GS and CE-certified

- Skirting protection of the control elements for protection against damages

- Bin is continously welded

- Circulation of the waste due to rounding at the discharge opening. Therefore, high filling weights are assured

- Completely “Made in Germany” by qualified and experienced staff

- Quality hydraulic pump with central hydraulic block

- Adjustable pick-up pistons to adjust on various skip-lift vehicle manufacturers

- Autotimer

- Overload protection

- Purely hydraulically controlled and, thus, durable reversing valve

- Central bolting device with durable, attractive spindle catch

- Wedge bolting device for maximum watertightness

- Optical oil level indicator and oil level monitoring

- Working hour counter

- TÜV, GS

- ¾ full and/or 100% full signal

- Full signal via GSM Module to you or disposer

- Certified watertightness due to liquid filling

- Manually or hydraulically operated lid covering the loading aperture in various versions (protects against filling by unauthorised persons and the penetration of rain water)

- Rubber seal of the lid (reduces odors, prevents penetration of rain water)

- Integrated lift-tipping-device for bins with pivot take-up (lifts the waste bin and tilts the contents into the compactor)

- Comb lifting system for the tipping-device

- Key switch instead of start button

- Rolls in the back and pick-up piston on the compaction blade for roll-off skip loaders

- Remote control via cables

- Photo electric cell in the filler area (machine starts, as soon as something is thrown into the funnel tube)

- Fire fighting point

- drainage device

- … and many more

- … ask for special versions

Everywhere, where garbage with a high liquid portion accumulates, as in:

- Supermarkets

- Large-scale catering establishments, hotels

- Department stores

- Hospitals and homes for the elderly

- Food productions

- Printing houses