- Home

- Companies

- OSEI - Oil Spill Eater International, ...

- Products

- OSEI - Model Eater II (OSE) - ...

OSEI - Model Eater II (OSE) -Biological Enzyme for Oil Spill Bioremediation

Oil Spill Eater II (OSE II) is the world’s most environmentally safe and cost effective bioremediation process for the mitigation of hazardous waste, spills and contamination virtually anywhere of any size, large or small.

OSE II offers reliable solutions for:

- Accidental Spill Response

- Spills on Land:

- Emergency Spill Response

- Liquid Spill Management

- Petroleum Spill Control

- Hydrocarbon Spill Remediation

- Marine Chemical Spill Response

OSE II offers an environmental superior alternative to conventional cleanup methods

OSE II provides comprehensive spill management and spill treatment, serving as a critical spill responder tool for petroleum spill control and hydrocarbon spill control. Its use supports adherence to EPA Spill Compliance and contributes to overall spill protection and spill contingency planning. OSE II is available as a portable spill control and mobile spill control product, suitable for various scenarios including marine chemical spill and general petroleum spill and oil spill remediation efforts. It is a vital component for effective spill preparedness and spill training programs for any potential spill event.

OSE II is an environmentally safe cleanup method because it uses natures own bioremediation processes to effectively eliminate hazardous materials.

OSE II is listed on the US Environmental Protection Agency’s National Contingency Plan for Oil Spills (NCP).

OSE II is not a bacteria (bug), fertilizer or dispersant product.

OSE II is a biological enzyme that converts the waste into a natural food source for the enhanced native bacteria found in the environment. The end result of this process is CO2 and water.

OSE II will reduce your cleanup costs and permanently eliminate the hazardous waste problem in place, with no secondary cleanup required.

OSE II is approved by numerous countries for use.

Since 1989, OSE II has safely remediated numerous types of hazardous materials on the ground, in the ground and in the water

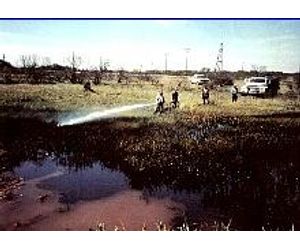

Texaco cleanup personnel preparing to mix OSE II

Crude Oil lifts off of sand as soon as OSE II is applied

Jet Fuel spill under F-18. Mixing OSE II prior to cleanup

Emergency Response Cleanup in Diesel spill

OSE II can be used virtually anywhere that can sustain Microbial Life

- Oceans

- Lakes, Rivers, Streams

- Where Fresh and Ocean Water come together (Brackish Water)

- All Types of Soil - Rocky Areas - Pebbled Areas

- Marshes - Estuaries

- Underground Soil

- Underground Water

- Under Buildings & Immovable Objects

(In-Situ)

- Animal Clinics

- Kitchens, Restaurants (Grease Traps)

- Manufacturing Plants that use Organic Based Natural Resources

- Manufacturing Plants that use Hydrocarbon Based Natural Resources

- Any Owner, Operator of Engines or Robotics

- All Transportation Groups - Air, Rail, Bus, Water

- Utility Industry

- Refineries, Oil Tankers, Drilling, Pipeline Operators

- Military, Governments, Fire Departments, Ports and Harbors

- Homeowners that spill Fuel, Oil, Pesticides, or Solvents

- Septic Tanks, Sewer Treatment Plants,

- Farms and Ranches

- Cleanup Contractors

- Insurance Companies - (Insurance Adjustors)

This list contains most of the hazardous material OSE II has bioremediated. It is not complete. We add new compounds continually. This list is to give you an idea of what OSE II can remediate. If your particular contaminant is not listed, contact us.

- Bioremediation of most Organic Based Compounds

- Bioremediation of almost all Hydrocarbon Based Compounds

- Bioremediation of all types of Gasoline - Diesel Fuel, Jet A, JP 4, JP 5, JP 8

- Bioremediation of Crude Oils

- Bioremediation of Pesticides

- Bioremediation of DDT

- Bioremediation of Malathion

- Bioremediation of Organo Pesticides

- Bioremediation of Tert Butyl Ether

- Bioremediation of Benzene

- Bioremediation of Xylene

- Bioremediation of Toluene

- Bioremediation of Ethyl Benzene

- Bioremediation of Chrysene

- Bioremediation of Hopane

- Bioremediation of Hexadecane

- Bioremediation of Naphthalene

- Bioremediation of Fluorene

- Bioremediation of Phytane

- Bioremediation of Phenanthrene

- Bioremediation of CI8, C30

- Bioremediation of Pristane

- Bioremediation of Heating Oils

- Bioremediation of Kerosene

- Bioremediation of Grease from Animals

- Bioremediation of Grease from Vegetables

- Bioremediation of Dioxins

- Bioremediation of Furans

- CreosotePCBs (Poly Chlorinated Biphenols)

- Dry Cleaning Fluid - (Perchloralethylene)

- Ethylene Glycol - (Radiator Fluid)

- Deicing Agent

- Hydraulic Oil

- Brake Fluid

- Power Steering Fluid

- Motor Oils

- Co Polymers

55 Gallon drum

size 23 inches in diameter by 39 inches in height

weighs 450 lbs

4 drums will fit on a pallet

a pallet is 42 inches by 42 inches by 43 inches tall

a pallet weighs 1800 lbs

1, 40 foot container holds 80 drums of OSE II

1, 20 foot container holds 40 drums of OSE II

OSE II drums are not stackable

OSE II 5 gallon containers

1, 5 gallon Box container of OSE II comes with 2 – 2.5 gallon containers

1 OSE II Box is 15 inches by 10 inches by 16 inches

1 OSE II box weighs 42 lbs

330 gallon Wire Cage Non-Refundable tote is 40″ X 48″ X 46

Empty tote weighs 145 pounds

Tote with OSE II weighs 3,166.65 pounds per tote

Totes can be double stacked

Transportation Information

The OSE II harmonizing code is, HTS code is 3821.00.0000

OSE II is US Department of Transportation Class 55 non Hazardous

Not dangerous for conveyance under UN, IMO, ADRiRID.

Marine Transport (IMO/IMDG):

Not classified as Dangerous

Goods by the criteria of the International Maritime

Dangerous Goods Code (IMDG Code) for transport by sea.

Air Transport (ICAO/IATA):

Not classified as Dangerous

Goods by the criteria of the International Air Transport

Association (IATA) Dangerous Goods Regulations for

transport by air.

OSE II Container Size & Weight

55 Gallon drum

- size 23 inches in diameter by 39 inches in height

- weighs 450 lbs

- 4 drums will fit on a pallet

a pallet is 42 inches by 42 inches by 43 inches tall

a pallet weighs 1800 lbs - 1, 40 foot container holds 80 drums of OSE II

- 1, 20 foot container holds 40 drums of OSE II

- OSE II drums are not stackable

OSE II 5 gallon containers

- 1, 5 gallon Box container of OSE II comes with 2 – 2.5 gallon containers

- 1 OSE II Box is 15 inches by 10 inches by 16 inches

- 1 OSE II box weighs 42 lbs

330 gallon Wire Cage Non-Refundable tote is 40″ X 48″ X 46

- Empty tote weighs 145 pounds

- Tote with OSE II weighs 3,166.65 pounds per tote

- Totes can be double stacked

Transportation Information

- The OSE II harmonizing code is, HTS code is 3821.00.0000

- OSE II is US Department of Transportation Class 55 non Hazardous

- Not dangerous for conveyance under UN, IMO, ADRiRID.

Marine Transport (IMO/IMDG):

- Not classified as Dangerous

- Goods by the criteria of the International Maritime

- Dangerous Goods Code (IMDG Code) for transport by sea.

Air Transport (ICAO/IATA):

- Not classified as Dangerous

- Goods by the criteria of the International Air Transport

- Association (IATA) Dangerous Goods Regulations for

- transport by air.

- IMDG Marine No

- No hazardous constituents

OSE II Cleaned up a Major oil spill of 550,000 liters (150,000 gallons) in Nigeria, in less than three and a half weeks. 99.9% reduction of the oil in the water and 97.9% reduction of the oil on the shoreline with zero natural resource destruction, and since OSE II causes oil to float and remediate on the surface there were no marine species deaths. This spill costs less than $2 million dollars to clean up compared to similar spills in the United States. For example, the Kirby Marine spill, which was approximately 140,000 gallons cost $87,000,000.00 and the Santa Barbara pipeline spill of 150,000 gallons cost over $297,000,000.00. Not only were both spills very cost intensive for the United States, both suffered huge amounts of natural resource damages. OSE II, the proven safe for humans, non toxic to marine species, economical means to permanently remove oil from the environment, speeding up natures own process!

Featured Clean Up

OSE II Cleaned up a Major oil spill of 550,000 liters (150,000 gallons) in Nigeria, in less than three and a half weeks. 99.9% reduction of the oil in the water and 97.9% reduction of the oil on the shoreline with zero natural resource destruction, and since OSE II causes oil to float and remediate on the surface there were no marine species deaths. This spill costs less than $2 million dollars to clean up compared to similar spills in the United States. For example, the Kirby Marine spill, which was approximately 140,000 gallons cost $87,000,000.00 and the Santa Barbara pipeline spill of 150,000 gallons cost over $297,000,000.00. Not only were both spills very cost intensive for the United States, both suffered huge amounts of natural resource damages. OSE II, the proven safe for humans, non toxic to marine species, economical means to permanently remove oil from the environment, speeding up natures own process!

VIDEO: View Now

DOCUMENTATION: Read Now

Spot Soil Clean Ups PDF

- Dorchester Clean Up

- Pig Farm Clean up by Hazsolve Chile VIDEO

- Pig Farm clean up with OSE II by Hazsolve in Chile Presentation1

- Chile Pig Farm Application protocol for Yanini

- Chile Pig Farm test

- Marines performed a clean up at 29 Palms California

- Dallas Naval Air Station

- Soil clean up fresh water above ground or surface clean in situ

- UK OSEI distributors, A&S International, clean-up with OSE II for Dunton Technologies on large contaminated soil project.

- Kenya clean up on Soil, concrete and pipe equipment

- Venezuela soil oil surface spill clean up with OSE II

- Japan Tokyo, Soil demonstration with OSE II

- US Marines clean up 29 palms California, fuel and waste oil contaminated soil clean up with OSE II

- Louisiana, Brousard video 1, Soil contaminated with oil and cleaned up with OSE II

- Louisiana, Brousard video 2, Soil contaminated with oil and cleaned up with OSE II

- Louisiana, Brousard video 3, Soil contaminated with oil and cleaned up with OSE II

- Soil clean up fresh water below ground or surface under buildings clean in situ

- Deep Soil injection with OSE II – Columbia

- Illinois, soil core oil being pulled out of the soil core with OSE II

- Colombia, Cabeno Environmental injecting OSE II below ground to clean up subsurface contamination including ground water.

- Illinois, Chicago industrial site clean up, Cabeno Environmental injecting OSE II below ground to clean up subsurface contamination.

- Dallas Texas metro chemical and pesticide clean up under a building slab with OSE II

- Soil clean up Salt/ocean water above ground or surface clean in situ/shorelines

- South Korea, Muyon Port beach small oil spill clean up with OSE II

- Washington Tacoma, Chevron Bulf fuel terminal contaminated soil cleaned up with OSE II

- For additional information on the Tacoma clean up you review these 60 and 90 year biodegradation tests PDF

- Ground water clean up

- San Jose, California AT&T Ground Water Clean Up

- The Missouri Walnut Hill Grove Pipeline Break Contaminating Soil and Ground Water – remediated with OIL SPILL EATER II ( OSE II) – PPT (PDF)

- The Montana Malmstrom Air Force Base, And The US Missile Defense bases in Montana, Ground Water Contamination From Base Operations – remediated with OSE II – PPT (PDF)

- The Oslo Norway Volvo Service Center Under Ground Storage release of Waste Oil contaminated Soil and Ground Water, As was the river where the hydrocarbons flowed down – remediated with OSE II – PPT (PDF)

- The Missouri Dominator Truck Stop Under Ground Storage release contaminating Soil and Ground Water, Under the Pavement – remediated with OSE II – PPT (PDF)

- Fresh water clean ups, on lakes rivers, creeks, streams, or ponds

- OSE II Thane Creek Test

- Dallas, Texas waste oil clean up on fresh water creek

- Witchita, Falls Texas 5000 gallon crude oil spill on a small lake/pond cleaned up with OSE II

- Panama, Colon crude oil leaching from storage tanks, clean up with OSE II

- Texas, Dallas OSE II demonstration for the press on diesel in fresh water.

- Missouri, Lake and river water US EPA demonstration of OSE II on heavy in emulsion waste oil.

- Fresh water clean ups, in storage tanks, or pits

- Dallas Texas, Heating oil tanks float up 68,000 gallons of oil into a contained area, like a pit clean up with OSE II

- Texas Under ground storage/fuel tanks, removal and remediation clean up with OSE II

- India Thane Creek Heavy Bunker C oil demonstration on fresh water clean up with OSE II.

- Alaska, Anchorage, under ground fuel tanks removed and the contaminated soil was clean up with OSE II.

- Ocean water clean ups

- Saudia Arabia OSE II shoreline demonstration

- Persian / Arabian Gulf offshore platform spill clean up with OSE II

- BP Macondo spill Gulf Of Mexico, Waveland Mississippi, application of OSE II on the BP spill on the shoreline

- Louisiana Bp oil spill clean up demonstration with OSE II on CBS News.

- Lousiana Shell Beach OSE II clean up of waste oil and diesel during the BP Macondo/Gulf of Mexico spill.

- Philippines Coast Guard oversight and Philippine TV, shoreline clean up for a crude oil spill with OSE II.

- UAE shoreline crude oil clean up with OSE II

- Saudia Arabia near Al Kabar Saudia Crude on open water and shoreline clean up with OSE II.

- BP oil spill presentation for the city of Destin Florida, with a table top BP spill created tar balls remediation with OSE II.

- Bahamas demonstration on Clifton pier area oil leaks into the ocean

- Incheon South Kore demonstration of OSE II cleaning up Diesel fuel

- Mexico Vera Cruz oil spill on the Gulf of Mexico clean up demonstration with OSE II

- South Korea Hebei Spirit demonstration and clean up with OSE II.

- Philippines Estancia 2014 shoreline clean up with OSE II.

- Alabama, BP Macondo spill tar balls remediation in a small container, OSE II confirmed it was used by the Navy.

- Louisiana Grande Isle, BP Macondo Spilled oil with Exxon’s toxic Corexit Dispersant remediated with OSE II.

- Salt water clean ups, in storage tanks, or pits

- Arabian Gulf offshore platform spill clean up with OSE II

- Storage tank clean up of sludge

- Greece Cargo Hull

- Revetment, or Berm clean up around storage tanks

- Illinois clean up of oil and fuel inside the revetment area with OSE II Part 1

- Illinois clean up of oil and fuel inside the revetment area with OSE II Part 2

- US Department of Energy, storage tank valve leak, contaminated soil clean up with OSE II.

- University of Japan successful testing of OSE II on Tokyo underground fuel station contaminated soil clean up.

- Sludge clean ups in pits or tanks

- OSE II Storage Tank Clean Up Overview

- OSE II sludge clean up in tanks in Colombia

- Argentina, Tank bottom sludge clean up with OSE II.

- Pipeline clean ups refined or non refined product

- Nigeria Shell Cawthorn pipeline clean up on soil.

- Nigeria Shell, Bera contaminated soil.

- Colombia pipeline clean up on soil and water.

- Osage Oklahoma, OSAGE Indian reservation clean up with the US EPA approval for a pipe crude oil spill on soil and water, cleaned up with OSE II.

- Maintenance shop clean ups

- Terminals, refineries, processing plants/ process water Ports and Harbors, and manufacturing

- Greece, Bp Transfer terminal in Crete cleaned up with OSE II.

- Kentucky Refinery process water remediation with OSE II

- Mississippi, Pass Christian Harbor BP Macondo crude oil spill clean up.

- Vehicle maintenance and spill clean up, and surface spill clean ups, cars, small trucks

- Large vehicle and Equipment/construction equipment, maintenance and surface spill clean ups, Buses, large trucks, and equipment

- Colombia Large fuel/oil spill clean up with OSE II.

- Airplanes, jets, and airport maintenance, and surface spill

- Greece, Athens airport, fuel tanker turnover spill, cleaned up with OSE II.

- Large Vessels, boats/yacht maintenance, cargo hull cleaning, deck cleaning, bilge and Ballast water cleaning

- Mississippi, Pass Christian Harbor, bilge water clean up with OSE II.

- Ship/Large Vessel: Deck cleaning, Tank cleaning, Tank water oil contamination treatment Engine room cleaning, Anti pollution for releases into the water, Anti pollution prevention during Bunkering, Black and grey water clean up.

- Ship/Large Vessel. Cargo Hull cleaning

- Train spills, and chemical cargo tanker cleaning

- Railroad Clean Up

- On shore rig clean up, and rig washing, and effluent clean up

- Trinidad and Tobago BP well blow out clean up with OSE II.

- Offshore rig clean up and rig washing, and effluent clean up

- Brazil rig wash clean up with OSE II.

- Part 1

- Part 2

- Drilling mud clean up

- Drilling mud pit clean up with OSE II

- You can read more about OSE II in regards eliminating environmental footprint while cleaning drilling mud pit. PDF

- West Texas Odessa Drilling mud and cuttings clean up in pits from onshore drilling operations

- Southeastern Oklahoma drilling mud clean up

- Refinery Process Water Clean up

- Tremco Refinery, Texas, Clean-up of process water PDF

- Sommerset Refinery Process water clean up with OSE II Photos

- Dredging sediments or oil spill from dredging clean up in Rivers, Lakes or Oceans

- New York Hudson River OSE II Clean Up

- Concrete or asphalt/man made surface clean ups

- California Shop floor oil spill clean up with OSE II.

- Waste Treatment, pumping stations, Drains, nallas, river clean ups from manufacturing waste, and or human waste.

- Wylie Texas, Pumping station pump breakdown, OSE II used to remediate the oil.grease and waste so the pump could be pulled up clean and worked on.

- Texas Dallas Trinity River Waste Treatment Plant demonstrations, testing and clean up with OSE II.

- Waste treatment documents

- Human waste streams to the oceans, creeks, rivers, lakes, where OSE II destroys viruses.

- Manufacturing hydrocarbon based spill clean ups

- Transformer clean ups, soil and water

- Texas Greenville, power plant contaminated soil, cleaned up with OSE II.

- Wind turbine clean ups

- Department of Interior OSE II testing in Nantucket Sound for dielectric oil from turbines in the ocean.

- Power plant/PCB clean ups

- Department of Air Force Power Plant Clean Up

- Iran, OSE II used to remediate PCB’s by the Iranian Transformer Company. PDF and in English

- Coal clean up

- Filter Cake Clean-up

- UK OSEI Distributors A&S International Suez-Street Sweepings-Filter Clean-up with OSE II JUN 24

- Confined space clean up in an emergency clean up

- Making Fuels nonFlammable/Fire Departments

- Kenya, Applying OSE II to eliminate the flammability of fuels.

- Texas Wylie, OSEI Corporation working with the Wylie fire department to develop non flammabile end points for gasoline and diesel.

- Texas Plano, Fire elimination of fuels demonstration with OSE II for the Fire Department.

- Murphy Texas, fire department cleaning up 250 gallon diesel spill on concrete with OSE II.

- US Military Ft. Worth base Fire Department clean ups on tar mat under F-18’s and soil spills.

- Thailand Applying OSE II to eliminate the flammability of fuels.

- Texas Fire retardancy demo.

- Cold climate clean ups

- Antarctica OSE II used to clean up diesel fuel spills from storage tanks feeding generators.

- Deicing agent test summary, laboratory testing, and deicing – DFW Airport

- Various Spill Removals

Oil Field Service: PCM – Gel Blenders, Gel Hydration Blenders, Super Pods – Vortex Blenders adds Sand to the Fracking Gel, Process Trailers – Electric Equipment, Cement Pumps – Pumps down Casings, Transfer Trailers – C pumps to move the water, OSE II helps clean the Fluid Ends on Frack pumps, and Clean Packing Bores on Frack pumps in-between stages, OSE II – Also helps keep Equipment clean and the work area clean.

- Antarctica Remediation of Diesel fuel by University of Buenos Aires Dr. McCormick

- University of Alaska Fairbanks

- Exxon Dr. Steve Hinton testing of OSE II on released oil from the Exxon Valdez Oil Spill

- Alaska Anchorage underground gas station clean up

- Rent-A-Can company Eagle River Alaska diesel fuel spill on soil Clean-up

- Alaska Valdez Oil Spill, Homer Alaska Volunteer group Visual Observations of OSE II removing North Slope Alaska crude oil from the beach deposited from the Exxon Valdez oil spill

- USA Department of Interior (BOEMRE) under US through solicitation number: M08PS00094, award number: M09PC002 through their Bureau of Ocean Energy Management and enforcement Tested and Compared OSE II’s ability to remediate Dielectric oil leaking from wind turbines in Nan Tucket Sound a cold climate spill, and compare OSE II to Corexit 9500 and Corexit 9527, OSE II was successful while the two Corexits products failed

- The Oslo Norway Volvo Service Center Under Ground Storage release of Waste Oil contaminated Soil and Ground Water, As was the river where the hydrocarbons flowed down – remediated with OSE II

- Dallas Texas USA testing Deicing remediation a few months after application of OSE II

- AT&T Alaskom Alaska

- Norway, Oslo Fire Department and PGT Norway, Cleaning Up Of A Fuel Spill In Oslo With OSE II

- The US EPA RRT VII tested Oil Spill Eater II (OSE II) on a very heavy, viscous waste oil utilizing fresh water from two different sources: The Missouri River and the Blues Spring Lake. Heavy oil such as this generally forms a heavy emulsion and is difficult to break down based on its normal properties

- India Thane Creek heavy Bunker Clean up oil

- Dallas, Texas Heavy waste oil

- Haliburton of Colombia testing of OSE II on heavy in emulsion oil

- GAF industries Venezuela Crude for roofing tar

Halogenated Hydrocarbons remediation with OSE II

OSE II remediates PCB’s, the Iran Transformer Research Institute, research centers in Iran’s electricity industry, takes advantage of domestic and foreign scientific, technical and technological capabilities, while providing training, research and executive services based on the most up-to-date scientific and technical bases, in the field of testing, commissioning and monitoring. This research group tested OSE II on PCB’s where OSE II showed impressive results. Farsee English

- King Fahd University of Petroleum & Minerals Research Institute

- Center for Environment & Water – A REPORT ON THE EVALUATION OF OIL

- SPILL EATER II (OSE- II) PDF