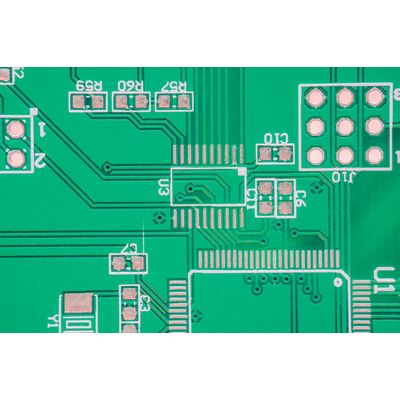

Blank PCB Board

Compared with other circuit board wiring methods, blank circuit boards require more design work. However, after the empty circuit board is assembled and manufactured, it can often automate. This makes a blank circuit board the cheapest and most effective option.

Use a blank circuit board after adding components. The blank circuit board eventually becomes a complete blank PCB board. If matched with the right ingredients, it will have multiple uses. Therefore, blank circuit boards have greater flexibility than single-sided circuit boards, double-sided circuit boards, and provide flexibility.

Use a blank circuit board after adding components.

The blank PCB board eventually becomes a complete circuit board. If matched with the right ingredients, it will have multiple uses. Therefore, blank circuit boards have greater flexibility than single-sided circuit boards, double-sided circuit boards, and provide flexibility.

When we make PCB, a blank PCB board is essential. Because all circuits and traces need to be operated on an blank circuit board, usually, the manufacturer will print a design on the blank circuit board to represent the circuit and then add components and soldering circuits to make the empty PCB board work normally. It can also see that the blank circuit board is the basis of all circuit boards.

There are many materials for making blank circuit boards, most of which have copper coatings. Some people say that the color of the material is about quality. This statement is wrong. The color of the material is just a personalized expression and has nothing to do with quality.

There is a copper coating on the surface because copper is an excellent conductor and heat resistant. The superior heat resistance of copper is good for the blank circuit board to work well with the current during use.

There are four processes in the production of circuit boards.

- Line draft — (drawing by PROTEL or other related LAYOUT software, and then transfer to transparencies or tracing paper)

- Exposure—(The photosensitive circuit board is illuminated by a desk lamp or exposure lamp to print the line draft on the photosensitive board)

- Development—(Use a developer to wash off the sensitizer after exposure, leaving a line draft)

- Etching—(Wash away the unnecessary copper foil and leave the lines we need)

Such a new blank PCB board is finished.

If you like and want to make a circuit board yourself, you can try to make a blank PCB board.