- Home

- Companies

- Sedifilt - Syntech Fibres (Pvt)

- Products

- Sedifilt - Bleached Cotton Cartridge

Sedifilt - Bleached Cotton Cartridge

Bleached cotton cartridge with stainless steel core meets food standards for use up to 130 C. For distilled water, beverages, vegetable oils, petroleum, fatty acids, and alcohols.

Test results have shown that Sedifilt filtration technology provides up to twice the dirt holding capacity and filter life at equivalent competitive efficiencies, while reducing pressure drop up to half. All this translates into improved filtration performance and reduced costs.

True Depth Filtration

Sedifilt depth filters have revolutionized filtration with a superior technology that overcomes the limitations and drawbacks of other filters.

Superior Filtration Technology

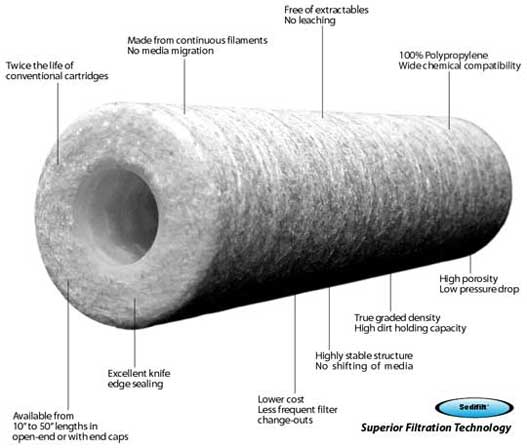

Sedifilt technology produces superior depth filters with increased filtration capacity, longer lifetime, and higher performance that reduce overall costs. Sedifilt filters have high structural integrity combined with a greater void volume, giving a lower pressure drop, much improved dirt holding capacity and efficiency compared to conventional filters. Sedifilt filters are made of polypropylene, a recognized environmentally safe and recyclable material for purity and ease of disposal.

- No chemicals to leach-out with new melt spinning and yarn forming process.

- No media migration because the yarn consists of continuous filaments.

- True graded density - new winding technology gives denser winding in inner layers and coarser winding in outer layers.

- High dirt holding capacity and longer life as particles are trapped throughout the entire cross section of thefilter.

- Better performance - multi-lobal cross section filaments with random 3-dimensional media structure captures more particles compared to conventional filters.

- High bulk media having improved void to solid ratio gives higher flow rates with low pressure drop.

- 100% polypropylene - wide chemical compatibility and excellent micro-organism resistance.

- High structural stability, i.e. no shifting of media, excellent knife-edge sealing.

- Firmer structure gives improved resistance to particle unloading and more consistent performance.

- Incinerates to trace ash with no hazardous volatiles for environmentally friendly disposal.

The patented Sedifilt process begins with 100% pure polypropylene that is melt-spun (extruded) without the use of any chemicals. The extruded media consists of continuous filaments of multi-lobal cross-section with numerous micro voids between each individual filament These chemical-free continuous filaments are then randomly oriented to each other, intermixed, looped and entwined into a non-round, highly stable, bulky yarn. The multi-lobal cross-section of filaments combined with the random yam structure gives much improved void to solid ratio. This improved porosity gives a higher dirt holding capacity and reduced resistance to flow.

When this media is wound into a filter cartridge, each of the filaments continues, without a break, throughout the length of the yam, making the cartridge free from any media migration problem. There are no short fibers that can come lose and migrate, a common problem with conventional string-w|ound filters. Each yam also traps the randomly protruding short loops of adjacent yarns resulting in a highly stable media structure wherein the yarns are locked in place and prevented from rolling or shifting aside. The stable structure provides an excellent knife-edge sealing property to the cartridge. Under conditions of varying flow and pressure fluctuations, the new cartridge is more resistant to particle unloading.

With the improved media, there are no typical diamond-shaped open spaces (a characteristic winding pattern of typical string-wound media) and the yam media covers all the area. The liquid flows through the entire yarn structure and contaminant particles are forced to change direction as they proceed through the depth of the cartridge. The physics of flow is such that it becomes possible to trap particles smaller than the size of the complex pathways.

Finally, through improved winding technology, the pitch, number of crossings and space between each yarn is continuously varied and controlled from start to finish in making the cartridge. The inner layers of the yarns are wound close together and the space between yarns is gradually increased towards the outer layers, while the yams remain locked together because of the random protruding loops. This winding technology gives improved true density grading, trapping coarser particles in the outer layers and finer particles in the inner layers. By maintaining the same winding tension, the structure has the same firmness throughout the depth of the cartridge, giving more consistent and better performance.

Sedifilt test results have shown that this patented process provides up to twice the dirt holding capacity and filter life at equivalent competitive efficiencies, while reducing pressure drop up to half. All this translates into improved filtration performance and reduced costs.