- Home

- Companies

- Bohn Biofilter Corporation

- Products

- Bohn - Biofilter

Bohn - Biofilter

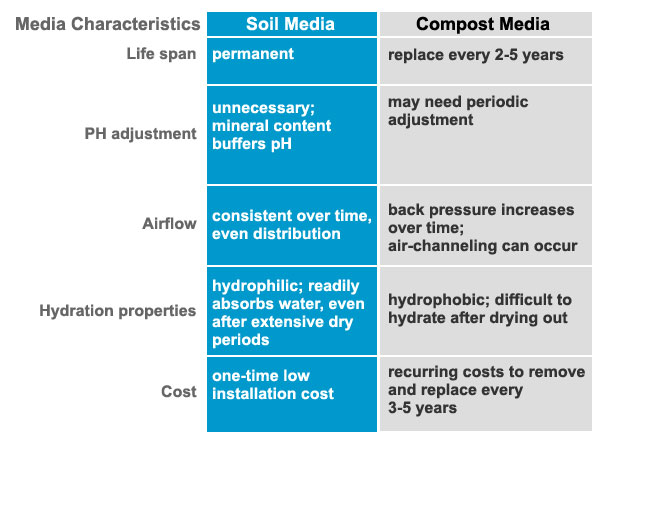

Bohn Biofilter supplies a complete system: All equipment and services for successful construction, operation and performance verification. The most important component of a biofilter is its media. For our filter media, we analyze regional materials and engineer a blend of soil products with an enhanced microbial population. The physical and chemical properties of our soil media makes it the most efficient biofilter material available.

- Soil is an excellent pH buffer. Low pH in biofilters/bioscrubbers causes corrosion and eliminates many microbial species.

- Wet or dry soils readily absorb water (hydrophilic), whereas compost/wood chip repel water when dry (hydrophobic). In the event of water system failures, bioscrubbers and other biofilters can fail. Soil Bohn Biofilters withstand water system failures for weeks on end.

- The physical properties of our soil media are stable for decades. This means stable airflow; consistent back-pressure and even air distribution.

Owners and operators enjoy the peace of mind that comes with a solution that practically works by itself. No filter change-outs. No chemical or nutrient additions. No pumps. The fan and moisture control will be the only necessary maintenance.

In sum, the neighbors will not complain about odor.

The most important component of a biofilter is the filter medium; commonly called media. We call ours “soil media”. Bohn Biofilter’s soil media is a blend of sands, soils and topsoils. The physical and chemical properties of this soil media make our biofilter the most effective available. These physical and chemical properties make a sturdy, stable substrate for biological activity. Stable airflow, consistent back-pressure and even air distribution is the result.

The chemical properties of our soil media makes for an excellent pH buffer. Low pH in other biofilters and bioscrubbers causes corrosion and eliminates many microbial species; species that degrade foul air gases.

Our soil media readily absorbs water (hydrophilic), whereas compost-wood chip media repel water when dry (hydrophobic).

If the irrigation fails, the soil media simply needs to be re-wet, not replaced.

Each soil media mixture is adjusted for mineral content, permeability, particle size and pH factors specified to each project.

Owners and operators enjoy the peace of mind that comes with a permanent solution.

Bohn Biofilter has a large market share in odor control for municipal wastewater and food processors. We also have applications for air stripping landfill gas, LFG, and hydrocarbon/BTEXs.

Bohn Biofilter has more than 250 biofilter installations in the United States, China and Canada as of January of 2016. Our systems efficiency has been proven successful in the diverse climate conditions of Arizona, Washington, Shanghai and more.

Ease of operation means reliability! A Bohn Biofitler runs all day, everyday. Fan maintenance is the only shutdown required!

Performance Verification

The basis of evaluating performance is inlet/outlet sampling. A typical inlet sampling location is shown in the photos below. Outlet gas samples are made in a flux chamber placed on the biofilter surface.

inlet gas sampling

These are reliable promises that our biofilter systems ensure:

- Maintenance is minimum: a seasonal check on our fan, irrigation and humidifier is standard

- Your OM budget will go much further than with other systems

- Your neighbors will not complain about odor

- It solves the odor problem every day with little to no downtime.

Our popular in-ground design incorporates the existing native soil as the biofilter’s containment walls. These biofilters are built either directly into the excavated ground with the finished surface at grade level or raised above grade with sloping earth-berm walls. The rugged simplicity of this design is not only cost-effective but also aesthetically pleasing.

In-ground biofilters are not confined to a rectangular shape; in fact, quite the contrary. In-ground biofilters can be configured in any shape and can thereby take full advantage of previously unusable areas around existing storage tanks, medians, or any other structure.

A unique feature of the in-ground biofilter is the ability to grow a lush grass cover on the surface.

Our biofilters can be built utilizing concrete containment walls. This design is appropriate for projects where it is not feasible to create an in-ground biofilter because of site limitations such as underground utilities.

Standard concrete construction methods such as pour in-place or precast walls are used to create an above-ground vessel. Whether built as one large biofilter or divided into multiple biofilter cells, these designs offer the flexibility of a modular design.