- Home

- Companies

- Zakłady Maszynowe Hamech Sp z o.o.

- Products

- Hamech - Boilers with Hydraulic Feeding

Hamech - Boilers with Hydraulic Feeding

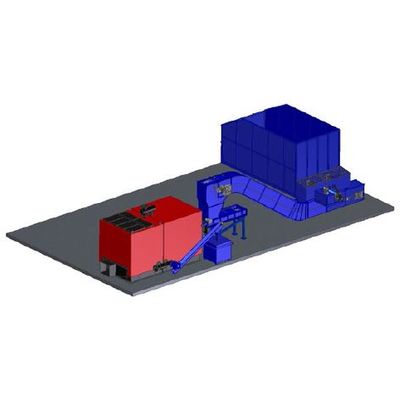

Heating set designed for burning mix of bark, sawdust and production chunk wood with granulation of: 50mm x 30mm x 300mm (max. moisture of 50%, whereas chunk wood is max. 50% of the mix contents) in order to produce hot water for heating or technological purposes. The set comprises boiler KWH-1000 with movable grate and hydraulic piston feeder powered with fuel from container selector KWP through Redler scraper conveyor.

The fuel container has a cubicoid shape. On the bottom there is a hydraulic selector housed, which slides forth and back on runners at the bottom of the tank. Thanks to their proper profile, discharger arms transport the fuel towards chute tray, where conveyor is installed.

The fuel from the container’s chute tray is transferred onto the scraper conveyor which comprises housing in form of a tray with chain falls, driving unit and tensioning mechanism.

The fuel is moved on a stationary chute surface with cross-bars arranged at double chain fall to the discharge from where it is delivered into fuel piston feeder chamber. Its main task is to supply the boiler with a portion of fuel while maintaining the adequate combustion parameters applied. The dozer piston is moved by hydraulic cylinder. The dozer features a two-step system for protection against feeder backfire which significantly improves the device operation safety.

In the boiler furnace chamber the moisture contained in the fuel gets evaporated and then the fuel is burnt. In order to ensure a uniform fuel distribution in combustion chamber the movable grate has been applied. It provides optimal combustion conditions and enables the material to be burnt completely. The grate is cooled with air which is also considered as the primary air for combustion.

Additionally the combustion chamber is fitted with an automatic ash removal system which significantly facilitates the boiler handling, particularly when burning fuels with low calorific value leaving large volumes of ash.

Fuel feeding and combustion processes are controlled automatically. The control system is based on a programmable controller, which controls fuel feeding using information received from fuel presence and heating power demand sensors. The controller is fitted with an easy-to-use touch panel.