Wilhelm Kurz & Söhne GmbH & Co. KG

- Home

- Companies

- Wilhelm Kurz & Söhne GmbH & Co. KG

- Products

- KURZ - Bolted Silos

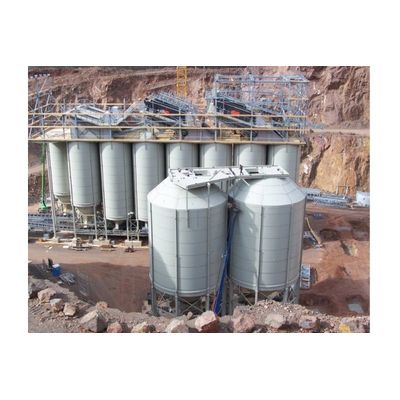

KURZ - Bolted Silos

Bolted silos are primarily used for storing large quantities of a wide variety of bulk materials. Gravel, crushed stone and sand, but also dusty bulk materials such as cement can be stored in bolted silos. The silos are manufactured in diameters from 4,647 mm to 20,000 mm. The assembly of the individual silo segments is quick and easy without special tools and special hydraulic rams. Due to the production of the silos in segments suitable for container transport, any location, even in the most remote areas, can be reached by truck, train or ship.

Most popular related searches

wastewater engineering

bar screen

wear protection

material crushing

drainage line

screening system

REACH training

environmental engineering

slotted pipe

Modifications

- Design with wear protection, e.g. rings in the cone, Hardox linings

- Drainage cones with bar screens or sheets and pipes with slotted holes

- Partition in single or double shell design

- Multi-chamber silos

- Breeches-type outlets for multi-chamber silos

- Silos with extended substructure and intermediate platform as loading silos

- Silos with roof

- Silos with complete enclosure or enclosure of the support structure

- Silo design to carry loads, e.g. filling equipment, screens and roof structures

Industries for bolted silos

- Cement & filler

- Non-metallic minerals

- Asphalt

- Power stations

- Mortar, plaster & paints

- Transshipment facilities

- Environmental and wastewater engineering

Benefits

- Price advantage of standard silos

- Individual designs and sizes available

- Large volumes possible

- Transport advantage

- Fast, simple installation due to precisely pre-drilled holes

- Absolute stability, even for very high loadings

- Perfectly leak-proof due to special bolted joints

- Better price than site-welded silos