Boreal - Stack/Duct (SDX) Probe Assembly

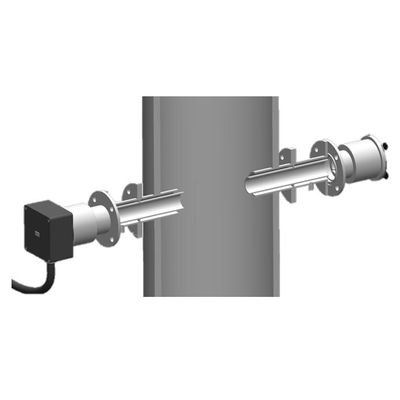

Non-Contact In-Situ Measurements: 3" 150# Raised Faced Flange Bolt-Up Pattern. Use in Hazardous Area Applications: (A) Ex ib IIC T5 Tamb less than 70°C Gb (C1 Div1, G: A, B, C, D). Quantifiable Volumetric Result: Confirmation of both gas type and concentration. Remote Measurement Head Paired with one of our GasFinder3 Instruments. Stack/Duct (SDX) Probe: When combined with one of the GasFinder3 Analyzers, it creates a direct and non-contact measurement within a stack or duct for quantitative or feedback control applications.

Larger Area Coverage

Monitor path lengths from 0.5 to 20 m (1.5 to 60 ft)

Fast Speed of Response + Recovery

New and independent result every single second

No Sensor Poisoning + Over Ranging

Ideal for frequent and/or constant gas exposures

Fail Safe Operation + SIL2 Suitable

Diagnostics with no undisclosed failure modes

Thrives Where Others Do Not Survive

Ideal for challenging monitoring applications

Need for Enhanced Performance

Early detection and rapid intervention saves lives

Capital and Operational Cost Savings

Long life span and minimal maintenance burden

Use in Hazardous Area Applications

(A) Ex ib IIC T5 Tamb

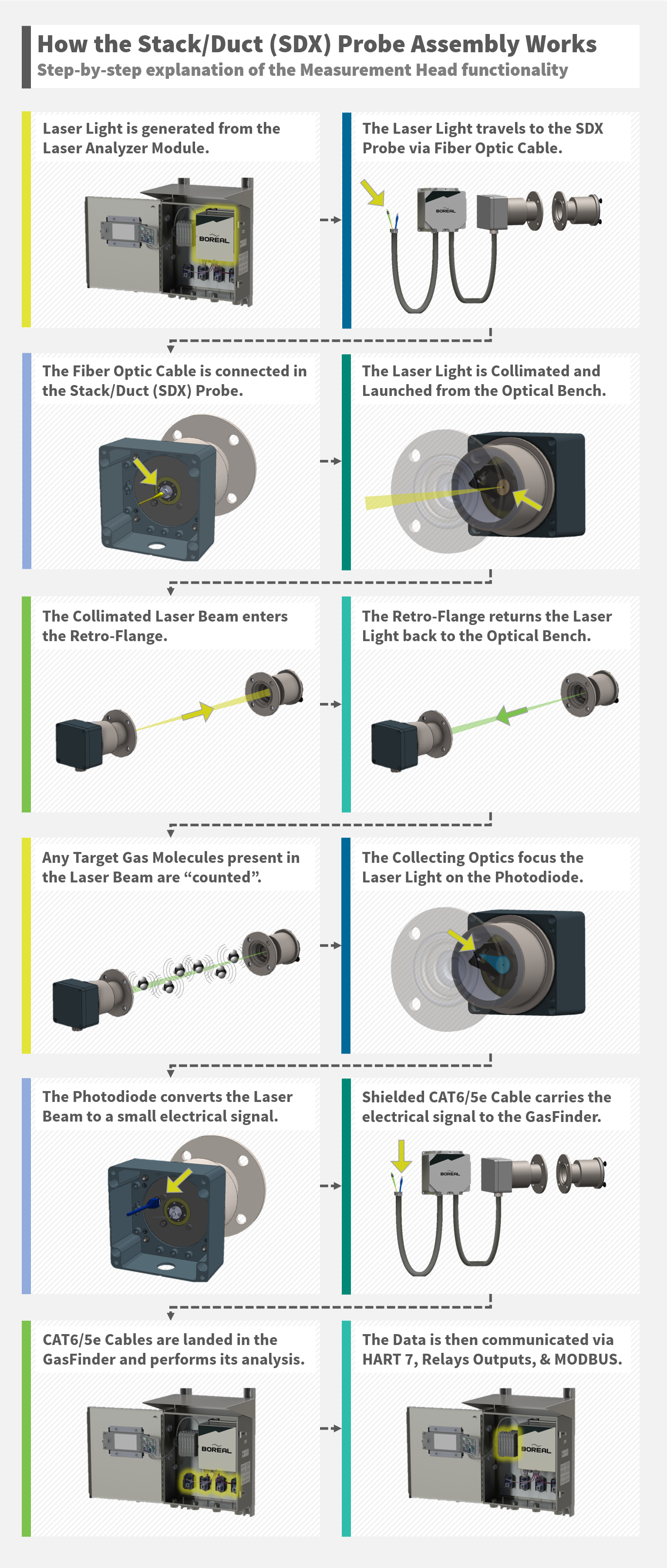

Laser Light is the Sensing Element

Class 1 Eye Safe: Near Infrared (NIR) laser light

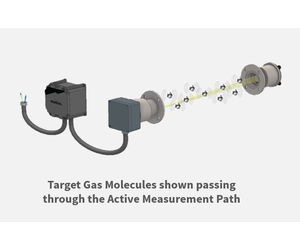

This Counts the Target Gas Molecules

As they pass through the Active Measurement Path

Quantifiable Volumetric Result

Confirmation of both gas type and concentration

No Interference + No False Alarms

This only detects the specific target gas of interest

Ideal for High Temperature Use

Nothing to overheat in the Stack/Duct (SDX) Probe

Easily Obtain + Maintain Alignment

Only the Stack/Duct (SDX) Probe need alignment

Superior Tolerance to Vibration

Vibration helps to integrate and quiet the analysis

High Laser Power + Tight Collimation

Optimized for greatest resistance to opacity issues

Configuration Options Available

To best understand if this Measurement Head is ideal for your application, it vital to understand what is included.

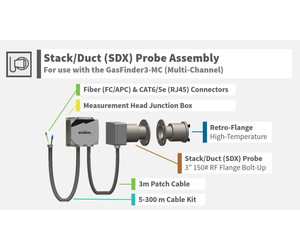

The Stack/Duct (SDX) Probe Assembly has the following configurable options:

- Cable Kit Length: From 5 to 300 m of Cabling between the Stack/Duct (SDX) Probe and the GasFinder.

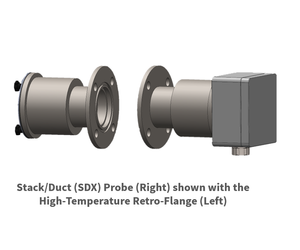

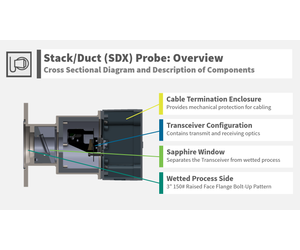

The Stack/Duct (SDX) Probe Assembly is comprised of the following components:

- Stack/Duct (SDX) Probe: This houses transceiver functionality and where the Fiber Optic and CAT6/5e are connected.

- High-Temperature Retro-Flange: These are like sections through a thousands of cubes and has three faces that form the inside of a cube and regardless of the angle of incidence of the incoming laser beam, the laser light is always reflected at 180° back to the Stack/Duct (SDX) Probe.

The Stack/Duct (SDX) Probe includes the following components:

- Cable Termination Enclosure: This is where the Single Mode Fiber Optic (FC/APC Connector) and Shielded CAT6/5e (RJ45) Cabling is landed and terminated.

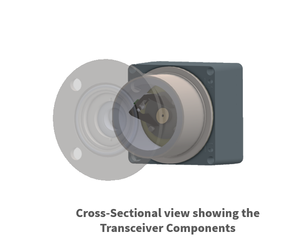

- Transceiver Configuration: This contains both the transmit and receiving optics on the Optical Insert.

- Sapphire Window: This separates the wetted process from the optical components.

- Wetted Process Side: This is where the direct and non-contact measurements take place.

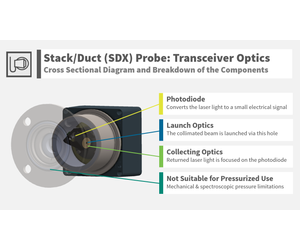

The Optical Bench includes the following components:

- Launch Optics: The Laser Light that travels from the GasFinder via Single Mode Fiber Optic Cabling is Collimated within the Optical Bench and launched from the hole on the Collecting Optics.

- Collecting Optics: When the Laser Light is returned from the Retro-Reflector the Collecting Optics focus the Laser Light onto the Photodiode.

- Photodiode: The Photodiode converts the collected Laser Light into a small electrical signal where the GasFinder will perform its Absorption Spectroscopy technique to very accurately and reliably determine the Path Integrated Concentration within the Active Measurement Path.

- Not Suitable for Pressurized Use: While this has a 150# Raised Faced Flange Connection, this is not to be used in pressurized applications for both mechanical and spectroscopic limitations.

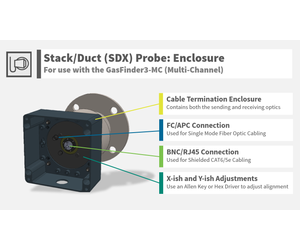

The Stack/Duct (SDX) Probe includes the following components:

- Cable Termination Enclosure: The Optical Bench can slide back out of the Remote Point (RPX) Probe Enclosure for easy termination of the Single Mode Fiber Optic (FC/APC Connectors) and Shielded CAT6/5e (RJ45 Connectors) Cables.

- FC/APC Connector: The Laser Light is carried from the GasFinder to the Open Path (OPX) Head via Single Mode Fiber Optic Cabling.

- RJ45 Connector: The small electrical signal from the Photodiode is carried to the GasFinder for analysis via Shielded CAT6/5e Cabling.

- X-ish and Y-ish Adjustments: With the use of an Allen Key, the technician can easily align the Stack/Duct (SDX) Probe to the orthogonally mounted Retro-Flange.

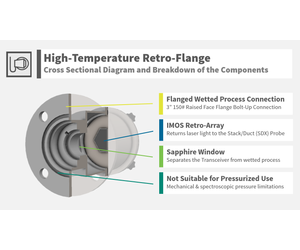

The High-Temperature Retro-Flange includes the following components:

- Flanged Wetted Process Connection: The Optical Bench can slide back out of the Remote Point (RPX) Probe Enclosure for easy termination of the Single Mode Fiber Optic (FC/APC Connectors) and Shielded CAT6/5e (RJ45 Connectors) Cables.

- IMOS Retro-Array: These are like sections through a thousands of cubes and has three faces that form the inside of a cube and regardless of the angle of incidence of the incoming laser beam, the laser light is always reflected at 180° back to the Stack/Duct (SDX) Probe.

- Sapphire Window: This separates the wetted process from the optical components.

- Not Suitable for Pressurized Use: While this has a 150# Raised Faced Flange Connection, this is not to be used in pressurized applications for both mechanical and spectroscopic limitations.

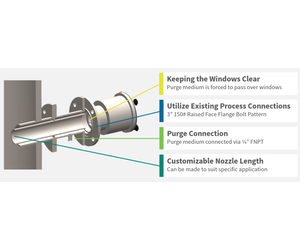

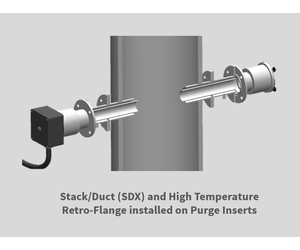

Keeping the Windows Clean

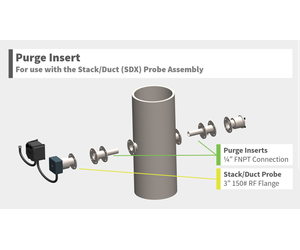

The Purge Insert is mounted between either the Stack/Duct (SDX) Probe and the Process Flange to provide a location to connect the purge medium (e.g. Instrument Air, Nitrogen, etc.).

The design of the Purge Insert forces the purge medium past the windows of the Stack/Duct (SDX) Probe and the Retro-Flange to keep the windows both clean and cooler.

For use with the Stack/Duct (SDX) Probe Assembly