- Home

- Companies

- Zhangjiagang Boxin Machinery Co., Ltd.

- Products

- Boxin - Model HDPE/PP - Plastic ...

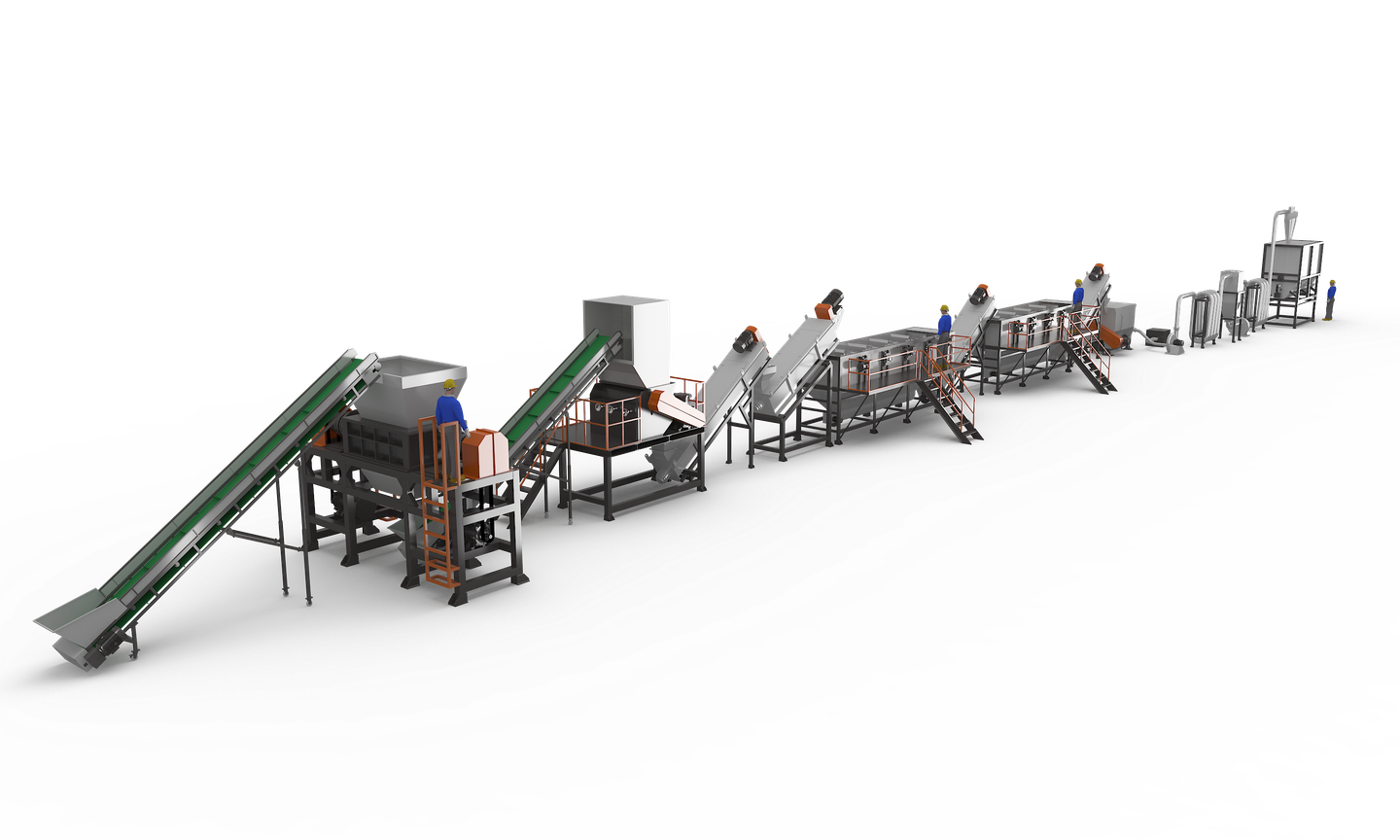

Boxin - Model HDPE/PP -Plastic Recycling Machine

HDPE/PP plastic recycling machine applies to milk bottles, engine oil bottles, big blue drums, environmental dust bins, plastic tables, chairs, etc.

HDPE recycling machine’s key factor is removing all kinds of impurities from the material. The single-machine design of different function performances is for the separation of the other modular forms that connect each unit.

Can promote the capacity expansion and industrial upgrading of the follow-up equipment with the most cost-effective input, eliminate the pollutants in the initial stage, save energy and reduce energy consumption, and effectively improve product quality.

Elements For Optimizing HDPE Recycling Machine

Ensure that the HDPE/PP plastic recycling machine is a smooth fit and achieve the recovery of the best rate key while optimizing the critical elements of the washing process. The following are the key elements to optimize the HDPE/PP plastic washing line:

Raw material supply

- High-quality raw materials improve cleaning efficiency and end product quality, including sorting and pulverizing different material plastics into suitable sizes.

Washing technology selection

- The appropriate cleaning technology is selected to eliminate bottlenecks depending on the type and degree of contamination of the used plastics.

Washing agent use

- Suitable cleaning agents help remove contaminants, grease, etc. However, using chemicals with greater cleaning power may cause irreversible damage to the material.

Water Treatment Optimization

- Adding a water treatment system reduces water usage, lowers wastewater treatment costs, and ensures compliance with environmental regulations.

Selection Of Equipment HDPE Recycling Machine

Choosing the right equipment is critical to efficiently building a hard plastic cleaning line. Some of the key considerations are listed below:

Crusher:

- The crusher breaks and splits the hard plastic blocks or crushes them into smaller particles, then processes them for subsequent processing.

Cleaning Systems:

- Cleaning systems remove systems and structures from the surface of plastic pellets.

Separation Equipment:

Separation equipment separates plastic pellets from others (e.g., metal and paper).