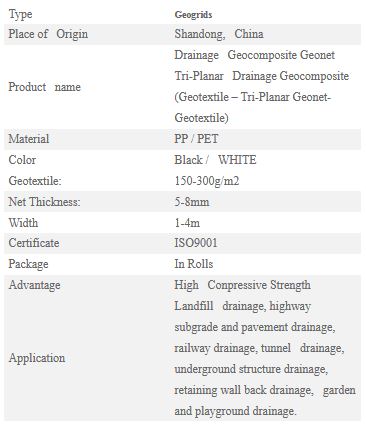

Boyuan - Drainage Geocomposite Geonet

Tri-Planar Roadway Drainage Geocomposite (Geotextile – Tri-Planar Geonet-Geotextile) The drainage geocomposite is comprised of a tri-planar geonet structure consisting of thick supporting ribs with diagonally placed top and bottom ribs, and with a thermally bonded non-supporting ribs with diagonally placed top and bottom ribs, ad with a thermally bonded non-woven geotextile. This product is capable of quickly removing subsurface water from the pavement. The product provides a void-maintaining system under high normal loads to work as a capillary break. Composite: Extruded high density polyethylene (HDPE) net drainage core with a nonwoven polypropylene (PP) or polyester (PET)geotextile filter/ separator bonded to both sides.

Net drainage geocomposites are manufactured using a unique geotextile filter developed specifically for use in drainage geocomposites for its high tensile modulus and ability to prevent soil ingress into the void space of the drainage core.

The drainage cores are manufactured from HDPE nets which have been engineered to have good flow under high loading.

- Drainage is strong. ((the equivalent of about one-meter thick gravel drainage)

- High tensile strength.

- To reduce the probability of geotextiles embedded into core, maintain long-term stability of the drainage.

- Long-term load is under great pressure. (Can carry about 3000 ka compression load)

- Corrosion resistance, acid and alkali resistance, long service life.

- Construction is convenient, shorten the construction period, reduce the cost.

Application: Landfill drainage, highway subgrade and pavement drainage, railway drainage, tunnel drainage, underground structure drainage, retaining wall back drainage, garden and playground drainage.

Applications include:

- Highways: vertical edge-of-carriageway drains intercept the lateral flow of ground water. Modern fin drains reduce excavation, reduce backfill quantities and reduce installation time. In-slope drainage increases geotechnical stability.

- Retaining walls and bridge abutments: to reduce pore water pressure and avoid backfill saturation.

- Engineered landfills: with the additional requirement of long-term chemical resistance and high compressive strength.

- Tunnels: ground-water-seepage interception between rock face and the tunnel lining.

- Buried structures: vertical and horizontal drains for basements, culverts, car parks, reservoirs, etc.