- Home

- Companies

- Black Powder Solutions Inc.

- Products

- BPS - Magnetic Separator Systems

BPS - Magnetic Separator Systems

Black Powder Solutions’ (BPS) Magnetic Separator Systems are inline, full-flow systems for removal of ferrous and non-ferrous contamination (Black Powder™) from fluid and gas systems.

These systems employ a Magnetic Array within an engineered pressure vessel that maximizes dwell time and particulate removal capability with minimal pressure drop (~0 psi ΔP in a clean system). Each system is engineered to achieve 99%+ efficiency in removing Black Powder contamination of all ferrous particles by accounting for design parameters such as flow rate, pressure, temperature, viscosity, medium and others. BPS Magnetic Separator Systems have the option of manual and semi-automatic cleaning systems, require minimum of consumables, require no fuel or power (manual cleaning) and have a 15+ year operating life.

We will work with you to utilize our existing Separators, or create a custom unit to best fit your footprint, environmental requirements, and maximize the quality of your product to increase value.

BPS Magnetic Separator Systems require cleaning rather than filter disposal. Each system offers long life service and utilizes minimal consumables. The high loading capacity allows for extended maintenance intervals of 1.5 – 3x depending on the density of the contamination in the particular system.

- Extended life of critical operating systems

- Reduction in downtime and lost production due to higher efficiency contamination capture

- Reduction in downtime and lost production due to extended service intervals

- Improved product quality

ORDERING:

Engineering Certification: ASME, U-Stamp, CRN, PED, CE, other as requested

Design Code: Available upon request

Area Classification: Class I, Div I, Div II

Warranty: 1 Year

OPERATING:

Maintenance Interval: 6-24 Months (average)

Operating Life: 15+ Years

Material: 304 SS, 316 SS, Duplex, Carbon Steel, exotic alloys

Configuration: Single, Duplex, Offset, Inline Ports, other as requested

Modular Design: Scaled to flow and contamination requirements

Cleaning Mechanism: Manual, Semi-automatic, Fully-automatic

INLET / OUTLET SIZE:

Low: 1” (Equivalent)

High: 72” (Equivalent)

VENT / DRAIN SIZE:

Low: 1” (Equivalent)

High: 12” (Equivalent)

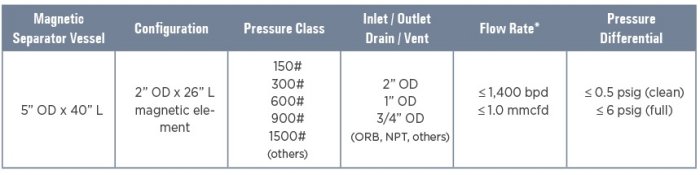

OPERATING DATA FOR A SINGLE MAGNETIC SEPARATOR:

*Based on a 2″ OD Magnetic Separator Element

*Duplex Magnetic Separator Systems are available to accommodate higher flow rates

FLOW RATE:

Liquid: ≤ 200,000 bopd

Gas: ≤ 300 mmscfd

DESIGN PRESSURE:

Low: ≤ ANSI 150

High: ≤ ANSI 2500

DESIGN TEMPERATURE:

Low: Cryogenic Service

Upper Temp. Limit: < 600 ºF (Magnetic Element Array)

Efficiency: > 99% +

Clean Pressure Drop: < 0.5 psi

Vibration Resistant: Yes

Magnetic Separator Element: Patented technology

Black Powder Separation: < 0.5 μm — 500 μm

Cleaning of the internal Magnetic Element simply requires the use of a cloth or glove to wipe contamination for disposal, or into a sample jar for laboratory analysis. As with all contamination analysis, BPS recommends performing Particle Size Distribution (PSD), X-Ray Diffraction and Energy Dispersive X-Ray Spectroscopy (XRD/EDS) tests to determine particle composition, size, metallurgy and concentrations.

- Manual. The Manual Cleaning System is a full standalone system. The user removes the Magnetic Element from the vessel and installs it in the cleaning station. The Magnetic Element is lifted through the scraper plate allowing the contaminants to be collected in the containment bag.

- Semi-Automatic. The motor and the gear box attach to the davit arm. The large and small blind flange are at the top of the vessel. The small blind flange is removable, giving easy access to the internal screw and coupling. Rotation of the screw cap by the motor and gear box allows the BPS Scraper Plate to move up and down along the rods.

- Fully-Automatic. This system utilizes a PLC to control pneumatic actuated valves to divert flow into the magnetic separator and again to bypass for cleaning operations once scheduled or contamination loading capacity is reached. The PLC then activates the motor which is always be connected to the extension drive through a packing gland or mechanical seal eliminating the need to remove the small semi-auto access blind flange. The motor drives the BPS scrapers assembly up and down the Magnetic Separator Elements.

BPS also manufactures single Magnetic Element Sample Stations, where one/some of the following are required:

- Identifying the source of the contamination, including policing third party deliveries;

- Capturing contamination for the purposes of analyzing contamination composition and particulate size analysis;

- Determining contamination loading, such as Total Suspended Solids (TSS), at different flow rates; and/or

- Determining the efficacy of Magnetic Separation in a particular application.

BPS Sample Stations are typically configured with the following specifications or designed to a client’s specific requirements. All our Sample Stations utilize engineering stamped pressure vessels (U-Stamp, CRN, CE, PED), are equipped with pressure differential gauges and are skid-mounted for ease of installation.

Taking proper samples will assist in long term planning and reduce pipe ware extending the life of your system.

Our Sample Stations are also configured with sample ports in order to allow for product sampling before and after Magnetic Separation has occurred. The Magnetic Element is easily removed from the Magnetic Separator and can be weighed for the purpose of determining contamination loading prior to the contamination being wiped from the Magnetic Element. We always recommend laboratory testing such as XRD, EDS, Particle Size Distribution (PSD) and TSS of the before, after and removed solids samples from multiple separate tests to properly understand the particulate contamination in a given system.

As a result, some operators trade-off amine system reliability in favour of conventional separators that have a higher micron setting than required. This would keep filtration costs down, but cause ongoing maintenance issues in process equipment such as heat exchangers, regenerator columns, reboilers and carbon beds. These costs can often be viewed practically as a cost of doing business. Other operators set their separators at lower ratings, such as 5 microns, to combat these system reliability issues. However, their filter replacement costs are higher and often embedded in the company’s P&L without consideration for improvement. Further, Black Powder in the sub-5 micron range continues through systems, allowing unnecessary maintenance expenses.

Black Powder is often seen by facility-level operators in their day-to-day jobs, regardless of what type of oil and gas facility they work at or where in the world they are doing that work. Some notable occurrences of this type of particulate contamination are:

Upstream

- In produced oil and natural gas. It fills separators, drops out in pipelines, in crude batteries and in tankage.

- It causes erosion and excessive equipment maintenance, increases filter and chemical costs and needs to be cleaned from vessels, batteries and tankage.

Natural Gas Pipelines

- In all natural gas streams. It collects in gathering, transmission and distribution pipeline systems, particularly in bends and risers; it enters compressors and gas plants.

- Drives pipeline erosion, drives compressor and pipeline maintenance, increases filtration costs and disrupts plant processes.

NGL Facilities

- In NGL mix, purity products and condensate. It collects in pipeline systems, enters fractionators, downstream pipelines and loading terminals.

- Causes pump repair and replacement, impacts meter calibration, plugs valves and filters, disrupts loading operations and causes off-spec product rejection.

Refineries

- In crude feedstock. It enters due to BS&W specifications, method of transport (ie. dirty barges), and introduced chemicals causing it to stay in solution.

- Disrupts desalter operations, plates out towers and trays, seizes pumps, excessively plugs filters, fills facility pipelines, disrupts amine processes and degrades intermediate and finished product quality.

Batch Product Pipelines

- Enters pipelines from contaminated refined product and condensate streams and builds via erosion.

- Drops out in tankage and storage, causing early retirement of pumps and excessive filter replacement, degrades fuel quality and performance.

Black Powder is present in these types of applications and facilities around the globe. North American regions such as the Permian, the Bakken and parts of the Western Canadian Sedimentary Basin are particularly noteworthy for its presence. More broadly, operators in the Middle East often deal with thousands of pounds of Black Powder in natural gas pipeline systems during pigging activities, although it is also present extensively in crude oil and produced water. Facility operators in Eastern Europe and Southeast Asia also deal with it on an extensive basis.

Seven Ways Magnetic Separation Changes the Game

Magnetic Separation offers a simple but elegant solution to manage both Black Powder and the maintenance vs. reliability trade-off. Magnetic Separators offer high-efficiency removal of Black Powder contamination from all hydrocarbon systems without the need for extensive replacement of filter elements.

- Utilize high-strength radial field permanent magnetics which do not require electricity.

- Remove ferrous contamination to 99% + efficiency regardless of size, from below 0.1 microns to above 500 microns. Remove non-ferrous contamination due to the principals of electrostatic charge and particle adhesion.

- Only require cleaning of the internal magnetic elements and then the system is put back into service – eliminating the management and disposal of thousands of single-use filter elements each maintenance period.

- Can be located upstream of currently installed conventional filtration systems to reduce or eliminate conventional filter replacement.

- Substantially decrease the environmental footprint associated with black powder removal and disposal.

- Hold hundreds of pounds of contamination before cleaning is required. This minimizes employee interaction, reduces ‘touch points’ (ie. improving HS&E performance) and lowers costs.

- Do not wear out – Magnetic Separator Systems are a permanent, long-term solution – 15+ years.

Operators can conduct site, regional or even enterprise-wide contamination impact assessments to understand the financial, safety and environmental impacts of Black Powder contamination and estimate the ROI of addressing contamination. Such an audit provides key data needed to rank investments in advanced filtration solutions such as Magnetic Separation, along with other corporate investment options.

The payback of investing in Magnetic Separation is typically less than 6 months, and often less than 1, due to reduced disposable filters costs, equipment repair and maintenance reductions and improved uptime. The cost and operational advantages of these systems are significant and will improve operational reliability and drive sustainability within the organizations that use them.