- Home

- Equipment

Refine by

Albany Environmental Equipment & Supplies

17 equipment items found

Manufactured by:Albany International Corp. based inRochester, NEW HAMPSHIRE (USA)

In the dryer section, the paper sheet travels around large-diameter heated cylinders, where remaining water is removed by evaporation. Dryer fabrics hold the sheet in close contact with the cylinders through the dryer section. Dryer fabrics must be heat resistant, rugged, and designed for both drying efficiently and evenly. Dryer fabrics can last much longer than forming and pressing fabrics ...

Manufactured by:Albany International Corp. based inRochester, NEW HAMPSHIRE (USA)

In the press section of many paper machines, a shoe press has replaced the conventional press. The shoe press increases dryness and enhances sheet properties by lengthening the time the sheet is under pressure. In response to the demand for improved water removal, Albany International developed the first grooved shoe press belts to provide maximum water removal, and the TransBelt to overcome the ...

Manufactured by:Albany International Corp. based inRochester, NEW HAMPSHIRE (USA)

In the press section of a paper machine, water is mechanically removed from the newly formed sheet. In the simplest press, the sheet is carried by a press fabric between two rolls, where water is removed with the application of load and pressure. This can also be assisted by the use of vacuum and heat. Press fabrics can last normally from 1 to 6 months. Albany International’s innovative ...

Manufactured by:Albany International Corp. based inRochester, NEW HAMPSHIRE (USA)

A sheet of paper is created in the forming section where a mixture of roughly 99% water and 1% cellulose fiber and filler materials is introduced evenly across the width of a forming fabric. The fabric acts as a conveyor and a dewatering device. As the fabric moves, water drains through it, while the fibers and fillers that form the paper structure form on the top of the fabric as the paper sheet ...

Manufactured by:Albany International Corp. based inRochester, NEW HAMPSHIRE (USA)

Albany International’s Nonwovens business designs and manufactures a full line of custom belting products for forming, conveying or drying nonwoven webs. More than a decade ago, Albany joined forces with Cofpa, a French company founded in 1966 as the heir of four other companies with a century-long expertise in paper machine feltmaking, to become the global nonwovens leader. With its ...

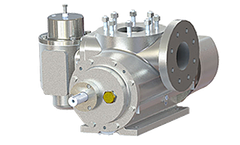

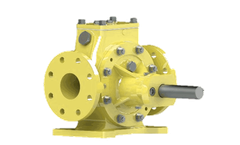

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

The SB Albany twin screw pump is similar to the Albany SA, but allows for a greater choice of sealing arrangements including API676 types and higher temperature and pressure operation. Again, with various heating options and internal relief valve choice, the range comes with a flexible sealing concept and complete heating jacket options. The range is ideal for more abrasive ...

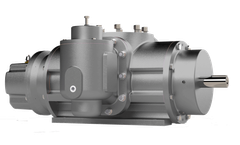

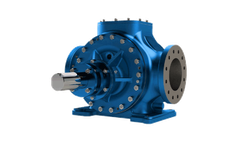

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

The SC style is only suitable for non-abrasive lubricating liquids. The bearings and timing gears are lubricated by the pumped liquid. It has only one mechanical seal making it a lower cost option with clean lubricating liquids. Heating and relief valve options are ...

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

The LA range of 3:4 rotor pumps is typically used for higher viscosity fluids running at reduced speed through gearboxes. Whilst these pumps are traditionally used in the sugar industry, they have many other applications. These pumps have a replaceable liner, with all other components designed for maximum efficiency and total life cost. Offering an economical solution to such pumping ...

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

The LB range of 7:8 rotor pumps is typically used for pumping chocolate at high pressure. These pumps have low NPSH advantages and are extremely slow running, making them ideal for the specific requirements of chocolate and similar materials. Internal or external bearing options are available for this ...

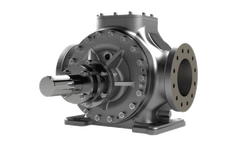

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

Lobe Pumps are smooth running elegant pumps. They are quiet and the fluid path through an Albany lobe pump makes them ideal for shear sensitive fluids. Their design allows high outlet pressures and long service lives. They are well suited to high viscosity fluids and either used with 4,6 or 8 pole induction motors or geared motors for the slower running ...

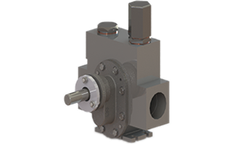

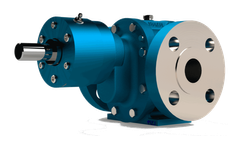

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

The GA range is Albany's general purpose gear pump, the origins of which can be traced back to 1901 when the company first started. It is capable of handling the widest variety of liquids, including extremely viscous liquids. These gear pumps offer a durable, robust design ensuring ease of use and maintenance. With a large choice of pump sizes, materials and sealing options to suit all ...

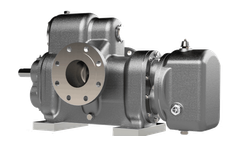

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

Albany's standard design with internally flushed DIN mechanical seals and external bearings for liquids with non-lubricating properties. It has an excellent suction lift capability of up to 7 metres. With single piece screw shafts for mechanical integrity and low flex. Available with sump heating options on some sizes. Also with or without an internal relief valve to comply with API 676. This ...

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

The GC range refers to compressor and turbine pumps, specifically designed to be used by OEMs in those industries. Fully capable, with a high system pressure layout, these C style pumps offer extra rigidity around the drive shaft and particular internal options. All of our pumps can be customised to include parts that help the customer's process or aid fitting into an existing framework, ...

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

Our C range of Centrifugal Pumps can be supplied as new pumps or as replacements in a variety of differing materials. Albany Pumps manufacture our own supply of long-established designs, first created by Stothert and Pitt. We manufacture Centrifugal Pumps to accommodate the heavy-duty requirements of applications, including foods and other types of cargo. Available in either horizontal or ...

Manufactured by:Albany International Corp. based inRochester, NEW HAMPSHIRE (USA)

Electric machines with stator or rotor sleeves have a wide range of application. Rotating sleeves for example are used for high speed rotors to protect magnets against centrifugal forces. Stator sleeves can be used to shield machine components from the process fluid, also called canned motor pumps. Composites are the first choice for such applications as they are almost transparent for magnetic ...

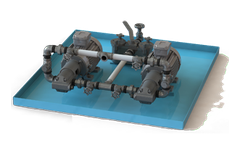

Manufactured by:Albany Engineering Company Ltd. based inLydney, UNITED KINGDOM

The GD range provides a ready made baseplate mounted twin pump system, with a main pump and a standby. When ordered, the product arrives on a baseplate ready to go with twin pumps, filters and suitable ...

Manufactured by:Albany International Corp. based inRochester, NEW HAMPSHIRE (USA)

Albany International’s Fibre Cement business designs and manufactures a full line of custom felts for the fibre cement industry. As the largest producer of fibre cement felts in the world, Albany’s ability to design, develop and improve upon its technologically advanced felts for more than 40 years has earned it a reputation of innovative leadership. In fact, Albany was a partner in ...