Promeco SpA

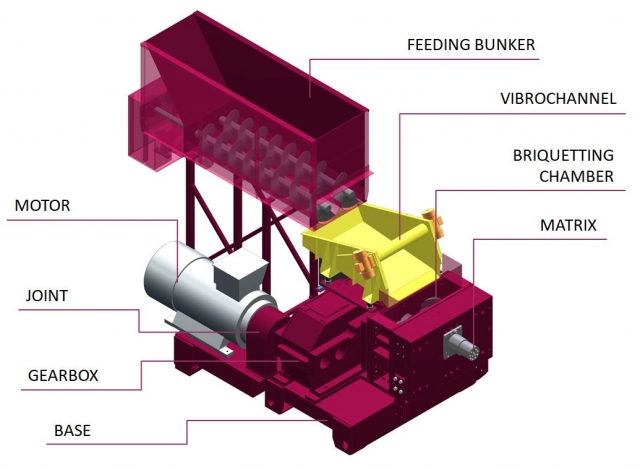

Promeco - Model PES600M400 -Briquetting Extruder System

FromPromeco SpA

The PES-Briquetting machine is the most flexible, efficient and effective machine to produce briquettes or pellets.

Most popular related searches

mixed plastic waste

briquetting system

mixed waste

briquetting

plastic waste

vibrating table

car fluff

pelletizing system

pelleting system

laboratory homogenizer

- RDF in fluff

- Mixed waste plastics

- Mixed waste

- C&I

- MRF reject

- ASR/car fluff

- Rifiuti misti

RDF briquettes

- Different shapes

- Size from 40 to 140 mm

- Compact, high adherence

- Density between 0,4 and 1,2 kg/dm³

- Humidity between 2 and 11%.

- Production capacity up to 3.000 kg/h

Pellet

- Size from 25 to 40 mm

- Water content < 1%

- Density > 1.000 kg/mc

- Completely homogenized

The material is fed to the feeding bunker and dosed by the vibrating table which homogenizes the material before the extrusion chamber. Here two counter-rotating screws exert friction on the material and take it up to 180°C to be melted. The melted fuse gets out from the discharge matrix.

The treatment capacity depends mainly on the characteristics of the input plastics. The production is about 1500 kg/h with input moisture < 15%.

- Less space required fir the equipment

- Lower power installed and used than normal system

- Simplified maintenance time and costs

- High productivity and versatility

- Low management and operation cost

Waste has different size, water content, density and composition variable so the PES densifier has been projected to handle this difference automatically in the best way.