- Home

- Companies

- Berkeley Springs Instruments LLC.

- Products

- BSI EagleArray™ - Pipeline Integrity ...

BSI EagleArray™ - Pipeline Integrity System

BSI`s Eagle Array™ - monitoring the internal integrity of thousands of miles of pipelines is a top priority for companies in industries such as oil, petroleum, natural gas, and electricity.

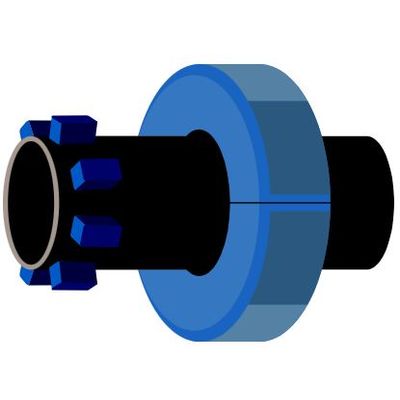

Rugged, field-ready, ultrasonic sensors built to withstand harsh environmental extremes. Field-proven, installed at wellheads, pipelines, refineries, chemical plants, utilities and underground pipelines. Positioned on the outside of your equipment for ease of placement and easy removal, BSI ultrasound sensors monitor the integrity of mechanical structures with incredible accuracy

FLEXIBLE INSTALLATION

Single or multiple sensor installations create a unified communication and processing system. Each sensor independently monitors for trends and exceptional events. Single and broadband waveforms can be generated and analyzed in order to identify potential flaws or deviations from the norm.

COMPREHENSIVE DATA SETS

Multiple readings at strategic locations along a pipeline reveal broad perspectives of a pipeline’s interior. Uniform data sets are used as a realistic predictor of corrosion or erosion conditions. Data is acquired remotely or with an Eagle Array™ IMPAcT™ data logger.

At BSI, we understand that not all applications are alike. The Eagle Array™ integrity system is designed for a variety of client-driven scenarios:

- Compatibility with local 110/240 VAC power

- Instrumentation DC power

- Solar power/battery

- Power over Ethernet (POE)

The Eagle Array™ has monitoring options that are beneficial in several ways:

- Plug and Play

- Sync-to-Cloud

- Data Logger storage