ARP Industry srl

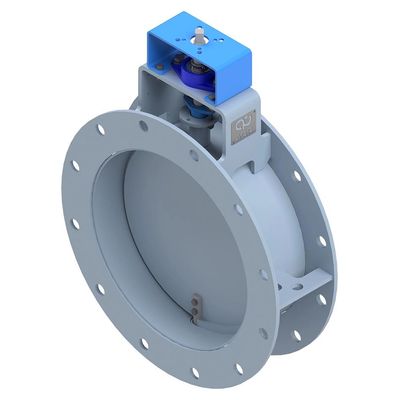

ARP - Model CS-L10 Series -Butterfly Damper Valve

FromARP Industry srl

All butterfly valve series are characterized by a circular cross section with concentric single or double blade. The double blade valve is the better choice for modulating service. Our butterfly valves can be designed as standard or heavy duty construction.

Standard fabrication is the optimal design in most applications. Heavy duty design is suitable for frequent service, highly corrosive applications, abrasive media and high temperature environments.

Most popular related searches

butterfly valve

butterfly damper

valve actuator

electric actuator

pneumatic actuator

damper

actuated valve

EN standard

- Diameter range DN150 ÷ DN2000

- Max temperature 200 °C

- Interception or modulating service.

- Designed for 50 mm insulation

- CE marking

Operating conditions

- Design temperature –40°C ÷ 200°C

- Design pressure –0,1 barg ÷ +0,5 barg

- Design EN 593, EN 12516, ASME B16.34

- Flanges EN 1092-1, ASME B16.5, other on request

- Testing EN12266, ANSI/FCI70-2

- Bolted flanges

- Wafer

- Butt welded

- No seal – Geometric tightness 96%

- Metal to metal – FCI 70-2 max tightness class II

- Harmonic steel lamellas – FCI 70-2 max tightness class III

- Soft sealing – FCI 70-2 max tightness class III/IV

- Top flange connections: EN ISO 5210, EN ISO 5211

- Manual with lever or handwheel

- EN 15714-2 Electric actuators

- EN 15714-3 Pneumatic actuators

- No seal

- Graphite braid packing

- Braid packing with lantern ring and air sealing

- Carbon steels

- CORTEN A

- Wear resistant steels

- Ferritic, austenitic and duplex stailness steels

- One external bearing

- Double shaft with two external bearings