- Home

- Companies

- FleetGenius, LLC.

- Products

- BWE - Model FL1_1 - Front Load ...

BWE - Model FL1_1 -Front Load Containers

“The BWE Design” is a premium designed front load container that matches or surpasses all standard ANSI specifications found in units offered in the market today, plus additional, innovative features which can extend the useful life significantly beyond that of an average container. These units are still competitively priced to maximize container value. The exclusive “Bakers Guard” protective coating which is applied to the full interior and exterior understructure, provides extra durability and extended life saving companies money in refurbishment and bottom replacement costs. Additionally, the Impact Single Wall Lid is more durable and lasts longer than any double wall lid available.

Why are more and more refuse haulers looking to BWE for their Front Load Containers?

Innovative designs, high quality steel construction, competitive pricing, and dependable delivery……providing waste haulers the edge they need to grow and be profitable

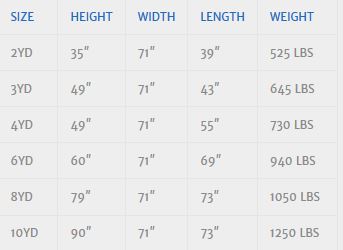

Standard and Heavy Duty Models available in 2 through 10 cubic yards

Fully welded interior for a 100% leak proof container

Main Body Styles include Flat Top w/ Hatchback (Notchback), Flat Top w/ Square Back, and Slant Top (all equipped w/ single or double wall plastic lids)

For added durability and corrosion resistance, BWE includes an exclusive “Bakers Guard” Protective Coating on the full interior and exterior understructure

BWE front load containers meet ANSI safety specifications and dimensions

BAKERS GUARDAn Exclusive Protective Guard for your Containers

This exclusive, rust inhibiting coating is a blend of asphalt petroleum and coal tar pitch materials and resins dispersed in petroleum solvents. Bakers Guard combines good abrasion resistance with good anti-corrosion properties. Bakers. When applied to metal surfaces, a barrier film is formed, thereby extending the useful life of the treated metal. This is a fast drying firm coating. The formula is environmentally friendly and has been tested with the following results:

FILM PROPERTIES

Performance testing reflects coating on unpolished Q panels with 7 day air-dried films at 2 mils dry.

Detailed FEL Product Features

- 10 ga Bottoms

- 12 ga Sides

- V – Crimps in front / rear panels

- 7 ga Blunderbuss Fork Guides and 10ga channel sleeves w/ vertical gussets and no-step plates

- All Top Channel Corners are interlocking providing extra strength

- Sides – 10 ga “W” channel

- Front – 12 ga “G” channel

- Rear – 3/16” structural channel

- Bump Pads are 18” tall, 7 ga steel w/ 1½” diameter rounded front

- Full length Bottom Channels w/end caps (2 x 4 x 10ga)

- 16 ga metal side doors w/ lock tabs

- 1.5” drain and plastic plug

- ½” hinge rods and 3/16” lid rod brackets

- Fully welded seams – No-Leak Guarantee

- Bakers Guard protective coating inside container with a full 8 mil thickness at the bottom, tapering to 3 – 4 mils at the top. Outside bottoms plus 3 to 4” to cover weld seams at bottom of walls.

- Outside coated with primer and topcoat. Paint is solvent (not water) base with UV resistant Industrial Enamel. 24 standard colors

- ANSI Z245 compliant

- Include Front Corner Structural Angle and Rear Corner Gussets for maximum container rigidity

- Notch Back design provides lid support reducing lid fatigue

- Notch Front design on 8yds provide extra cab clearance and protection

- Newly designed “Blunderbuss” sleeves for durability and easier access

- Integral side/door track to reduce damage and to avoid rust stains

- Impact Plastics Single Wall Lids w/ re-enforced lid rod “knuckles” – more durable and last longer than double wall lids

- 1 year warranty on container and 7 year warranty on Impact lids

- High Quality

- Innovative Designs

- Durable High Impact Lids

- Interior Protective Coating

- Built To Last!

General Product Specifications

- Walls – 12 gauge steel w/ “V” crimps

- Floor – 10 gauge steel

- Sleeves – 7 gauge “blunderbuss” w/ gussets

- Bumper Plates – 7 gauge steel

- Bottom Runners – 2 x 4 x 10 gauge steel

- Side Doors – Lockable 16 gauge steel

- Integrated, Formed Doors Tracks (top and bottom)

- Drain Port (1.5″) w/ plug

- Lids – single or double wall plastic

- Interior Protective Coating – Exclusive “Bakers Guard”

- Exterior Coating – 2mil primer + 2mil industrial enamel

Heavy Duty Upgrade Specifications

- Walls – 10 gauge steel w/ “V” crimps

- Floor – 7 gauge steel

Optional Features

-

- Plastic Side Doors (vs. steel)

- Metal Lids (vs. plastic)

- Automatic or Manual Lid Locks

- OCC (Cardboard) Recycle Slot (6″ x 60″)

- Standard Mobile Casters

- “The Glide” Custom Wheel System w/ Brakes

- Epoxy Protective Coatings