Linus Projects India

- Home

- Companies

- Linus Projects India

- Products

- Linus - Capping Machine

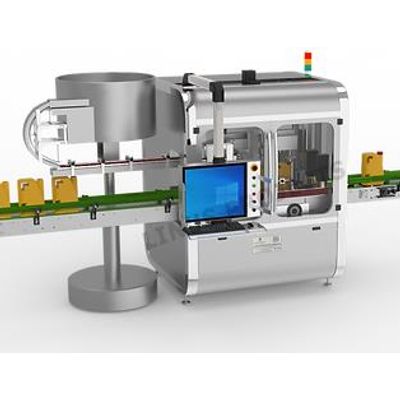

Linus - Capping Machine

The capping machine comprises of Cap Vibrator for cap orientation & Capping unit. The caps fed in the vibratory hopper are properly oriented here. The properly oriented caps are brought out through chute and supported at the end by spring-loaded fingers the containers as it comes out of the filling station move to the capping unit, where-in it picks up the cap and goes towards the capping head. The caps are subsequently tightened through a magnetic clutch system. The capped bottles finally emerge out of the machine through a discharge conveyor.

Most popular related searches

- The Capping Machine by Linus Projects boasts a precision capping mechanism that ensures a secure and leak-proof seal on lube oil containers.

- Linus Projects Capping Machine is compatible with a range of filling machines, including automatic, mechanical, volumetric, weigh metric, and gravity filling machines.

- The machine is equipped with adjustable capping heads, accommodating different container sizes and cap types.

- Linus Projects incorporates PLC-based controls into the Capping Machine, providing operators with precise control over the capping process.

- The Capping Machine seamlessly integrates into PLC-based filling lines, allowing for synchronized and automated operations.

- Lube Oil and Grease Industry

- Edible Oil Industry

- Chemicals and Lubricants