- Home

- Companies

- Carbochem Inc.

- Products

- Carbochem - Model IonPlus - Ion ...

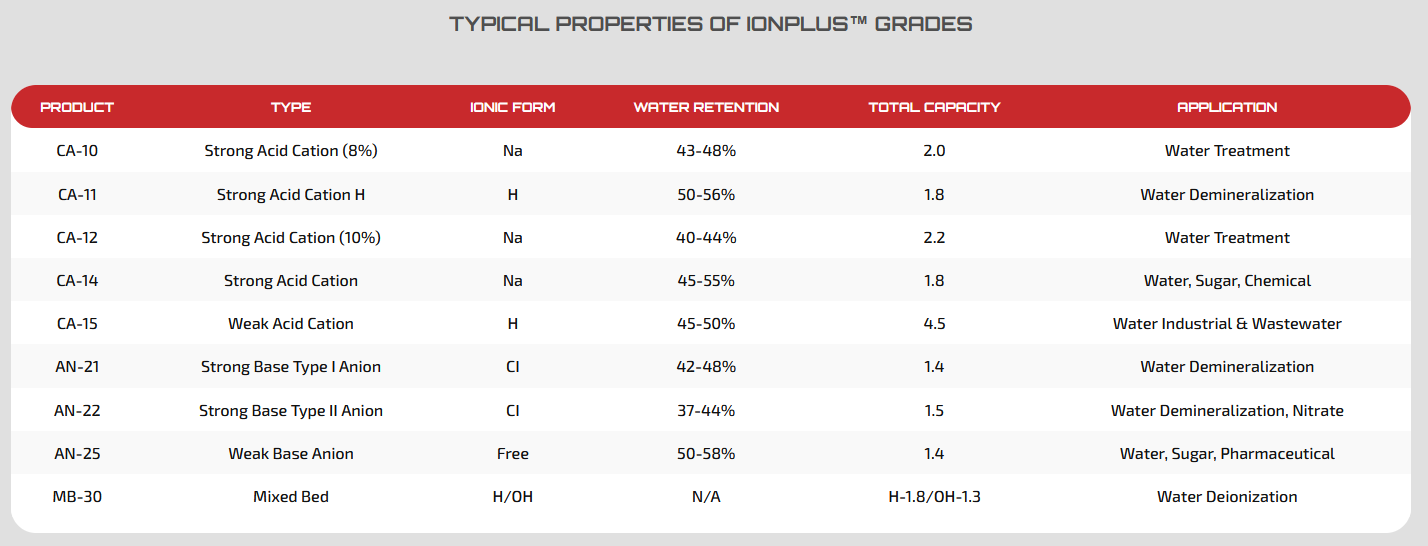

Carbochem - Model IonPlus -Ion Exchange Resins

Ion exchange resins are prepared from synthetic polymers such as styrene – divinylbenzene copolymers that have been sulfonated to form cation exchangers or aminated to form anion exchangers. IonPlus™ resins are produced under ISO 9001 certification and several of the IonPlus resins are certified for ANSI/NSF Standards 61 and 44.

Carbochem offers a full line of Ion Exchange Resins (cation, anion and mixed bed) for applications in household and industrial water softening, boiler feed water, food and beverage, sugar processing, electronics, and wastewater treatment. Resins can be tailor made to meet a customer’s specific requirements. Technical support and analytical services are available. High quality resins offered at a competitive price.

Major Markets

- Water treatment: softening, demineralization and metals removal used in industrial, residential, boiler feed, semiconductor, wastewater and power.

- Food and specialty processing: sugars, glucose, fruit juice, chlor-alkali

Quality

- IonPlus™ resins are produced with ISO 9001 and 14001 certification

- Steam washing process is used to produce clean resins

- Certificate of Analysis (COA) is provided with every batch

- Gel, macroporous

Activated Carbon Decolorizing Properties

Decolorizing applications involve removal of large molecular compounds which require activated carbon with a well developed macropore structure. The information provided here applies to sugar refining but the same concepts and principles apply to other decolorizing applications.

Adsorption Process of Activated Carbon

Activated Carbon is non-polar which results in an affinity for non-polar compounds such as organics. These compounds are bound to the surface of the activated carbon by the adsorption process, which utilizes Van der Waal’s forces. Since adsorption is a surface phenomenon, the adsorption capacity is directly related to the pore structure and surface area of an Activated Carbon and saturation is only achieved under equilibrium conditions. The equilibrium point is determined by parameters such as temperature, pH, concentration and contact time. Particle size only affects the rate of adsorption and has negligible impact on Total surface area, which is determined by the degree of activation and pore structure. It is important to remember that adsorption is not a selective process but will depend on the specific adsorption affinity of each compound which is related to parameters such as molecular size and solubility.

Properties of Activated Carbon

There is no universal activated carbon which is ideal for every application so it is important to match the properties of the activated carbon with the performance requirements of the process. The primary parameters used in the industry are given as follows with the corresponding indicators:

• Apparent Density – volume activity

• Iodine Number – surface area and micropore content

• Molasses Number/Caramel dp – macropore content (pore > 500 Å)

These parameters give an indication of the relative adsorption capacities of different activated carbons and their corresponding service lives for a specific process (even though an activated carbon may have a high surface area it also needs to have the right pore structure to be effective). Activated Carbon with a high macropore content will provide the best decolorizing performance.

Decolorizing Performance of Activated Carbon Key Parameters:

• Decolorizing Performance – pore volume

• Filterability – particle size

• Color Stability – removal of precursors of degradation by-products

Evaluation Process

It is important to establish a well defined Test Protocol so that the operating parameters are the same for each activated carbon being evaluated.

Fixed Parameters:

• Quality of feedstock

• Temperature

• Contact time

• Activated carbon dose rate

• Particle size of activated carbon

• pH of color measurement

Activated Carbon Selection and Optimization

• Granular activated carbon vs. powdered activated carbon

• Dose rate

• Contact time

• Particle size of activated carbon

• Temperature vs. viscosity

Carbochem Inc. has been supplying activated carbon to the sugar industry for more than 10 years and have developed the following specialized grades to optimize decolorizing performance:

1. Carbochem® DC-40 : granular activated carbon

2. Carbochem® CA-50 : powdered activated carbon

3. Carbochem® CA-50S : low dust powdered activated carbon