Carbolite - Model HB 18/80 -Top Hat Furnace

The HB furnace range has an automatically operated vertically moving hood for heat treatment in air as standard option. This design allows samples to be accessed from three sides. The HB can be equipped with CrFeAl heating wires up 1300 °C or with MoSi2 heating elements for temperatures up to 1800 °C.

The HB top hat furnaces are available with usable volumes of 80 to 560 litres. The hood moves up and down automated giving access to the hearth for loading and unloading. Alternatively the HB-BL 240 and HB-BL 430 litres model the hood is steady and the hearth moves up and down in a bottom loading way.

For debinding of technical ceramics, preheated air fans can be installed blowing hot air through the hearth into the furnace chamber. For safe combustion of binder gases several options are available, e.g. active propane gas after burner or catalytic oxidiser.

- 1300 °C, 1600 °C, 1700 °C & 1800 °C maximum operating temperatures

- Programmable EPC3016P1 controller

- From 80 to 514 litre capacities

- HB = top hat. HB-BL = bottom loading

- FeCrAl wire heating elements for 1300 °C models

- High quality molybdenum disilicide heating elements for higher temperatures

- Energy efficient low thermal mass insulation

- Over-temperature protection

- Ethernet communications

- A range of sophisticated digital controllers, multisegment programmers and data loggers with digital communication options is available - more information about controllers

- Gas inlet for operation under modified atmosphere (not gas tight)

- Preheated air blower up to 650°C

- Active propane gas after burner or catalytic oxidiser for safe combustion of debinding applications

- Reinforced base plate for a surface load of 500 kg/m2 instead of 250 kg/m2

- Bottom heater for improved temperature uniformity (this option cannot be combined with the reinforced base)

- Fast cooling options

annealing, ceramic injection moulding (CIM), debinding, debinding in air, degassing, drying, sintering, sintering in air, sublimation, synthesis, tempering

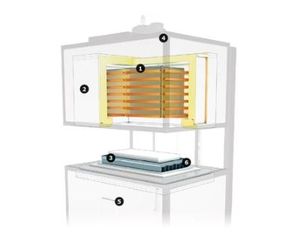

View inside of the HB Hood Furnace

- FeCrAl heating elements up to 1300 °C

- Low thermal mass insulation

- Top hat: steady hearth; Bottom loading: movable hearth

- Top hat: movable hood; Bottom loading: steady hood

- Frame

HB80

Max temp (°C): 1300, 1600, 1700, 1800

Volume (l): 80

HB160

Max temp (°C): 1300, 1600, 1700, 1800

Volume (l): 160

HB240

Max temp (°C): 1300, 1600, 1700, 1800

Volume (l): 240

HB430

Max temp (°C): 1300, 1600, 1700, 1800

Volume (l): 430

HB514

Max temp (°C): 1300, 1600, 1700, 1800

Volume (l): 514

- Uniformity between 800°C and Tmax (°C) [DIN 17052]: --

- Max. heat-up rate (°C/min): --

- Cooling time (h): --

- Dimensions: Internal H x W x D (mm): 780 x 1200 x 550

- Dimensions: External H x W x D (mm): 2700 x 2200 x 1400

- Max power (kW): --