- Home

- Companies

- Piyush Steel

- Products

- Piyush - Model ASTM A106 GR.C - Carbon ...

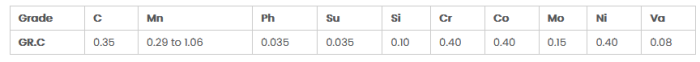

Piyush - Model ASTM A106 GR.C -Carbon Steel Pipes

ASTM A106 Seamless Pressure Pipe, A106 Carbon Steel Grade C Pipes, Carbon Steel GR C Seamless Pipe, ASTM A106 Grade C Seamless Pipes, Carbon Steel GR.C Seamless Pipe, ASTM A106 Grade C Pipe, Carbon Steel GR.C Pipes Supplier in Mumbai, India.

Piyush Steel is ASTM A106 GR. C Carbon Steel Pipes manufacturer and stockholder delivering to the whole world. We are an ISO certified firm to internationally approved quality standards for various types of applications. These pipes have excellent quality that satisfies customer’s requirements. The industrial pipes offered by us are accepted by customers in various sectors of industries from heat processing to manufacturing industries.

As an internationally admired firm, we are continuously developing and providing the best quality products and services that exceed the demands of customers. Our team of professionals is devoted to providing superior quality products and services to customers. The offered range of pipes is manufactured in different designations, specifications, custom dimensions and standards. We are also making these pipes in various non-standard dimensions for specific applications. We also are facilitated with advance machines and technologies, thus makes us able to improve each side of offering high end products.

The entire range of pipes is processed from a different stage of testing to ensure no chances of defected pipes production. In our large inventory, these pipes are stored in huge quantities so as to fulfill the urgent requirements of the customers.

ASTM A106 GR. C Carbon Steel Pipes are highly resistive to general and local corrosion as compared to conventional grades. These pipes offer great resistance to pitting and crevice corrosion in adverse environments. Moreover, these pipes are preferred for halide and chloride containing environments in the raised temperatures. It has great features such as higher creep strength, stress to rupture strength, tensile strength and many more. Advantageously, it is highly resistive to atmospheric corrosion.

Properties-

The steel pipes have great general corrosion resistance and have better resistance in strong oxidizing conditions. Also, it has great resistance to intergranular attacks in the exposure of chromium carbide precipitation range. ASTM A106 GR. C Carbon Steel Pipes have higher oxidation resistance and higher creep strength. Furthermore, this grade has well down temperature toughness. These pipes are designed for enhanced higher strength even in elevated temperatures. This alloy cannot be hardened by the heat treatment process; the only cold working operation is preferred. These pipes are weldable with all standard welding operation by a standard welding shop.

It posses great corrosion resistance and has the ability to stand in most difficult atmospheres. These pipes can be used in the exposure in harsh chemicals such as dilute organic acids, nitric acids at moderate to higher temperatures. The SS grade has higher thermal stability best for heavy and demanding engineering works. Because of formability, machinability, fabricability, these pipes are suitable for fabrication applications.

Its cold work hardening rate makes it highly machinable with the standard process, thus this reduce machining costs. To attain precise dimensions and surface finish these pipes are processed from the industrial finishing process. Furthermore, it is offered with a covering of oxidation prevent coats.

The structure of pipes is non-magnetic in nature and turns magnetic after the cold working operation.

Quality schema-

We at Piyush steel, further make sure that pipes deliver by us goes under various testing parameters and quality standards. In order to acquire quality goals, we make sure pipes are manufactured under set industrial parameters. We are ensuring reliability of pipes in most demanding severe applications.

With our latest testing facility, we are able to offer customers innovative and high end solutions of pipes. We are performing different types of tests on a manufactured range of plates.

The tests are-

- PMI test

- Chemical analysis

- Hydro test

- Compression test

- Leakage test

- Pitting corrosion test

- Thermal performance test

Other tests are-

- Mechanical test

- Ultrasonic test

- Radiography

- Macro test

- Micro test

ASTM A106 GR. C Carbon Steel Pipes are offered in various types of machining surfaces and finishes.

Markings On The Carbon Steel GR.C Seamless Pipes

The full identification of the pipe should be continuously marked down its whole length, including :

- Nominal Pipe Size (Nominal Bore)

- Schedule (Wall Thickness)

- Specification

- Grade

- Method of Manufacturer (Seamless)

- Heat Number

- Manufacturer’s Name or Symbol

- Specification : ASTM A106 / ASME SA106

- Seamless Pipe Size : 1/2" NB - 60" NB

- Outer Dimensions : 1/2” Nominal to 24”O.D

- Wall Thickness : Schedule 40 up to 4.000”

- Length : max 16000mm, Single Random, Double Random & Cut Length or As per customer`s

- Type : Seamless / ERW / Welded / Fabricated / LSAW Pipes

- Schedules : SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH120, SCH140, SCH160, XXS

- Form : Round Pipes, Square Pipes, Rectangular Pipe

- Petrochemical Industry

- Chemical Industry

- Oil and Gas Industry

- Pulp & Paper Indusry

- Power Plant Industry

- Food Processing Industry

- Pharmaceuticals Industry

- Energy Industry

- Aerospace Industry