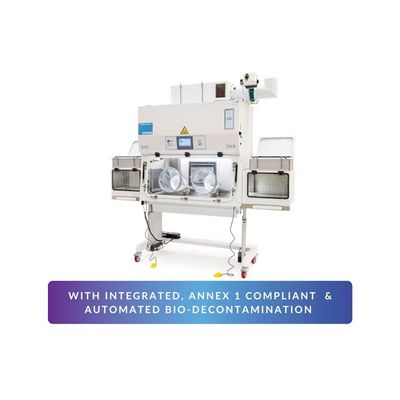

Our trusted pharmaceutical isolator, the CDC, is now available with validated and controlled bio-decontamination of the interior using a sporicidal agent in a vaporised form.

Capable of providing a 6-log overnight sporicidal kill, this closed loop configuration requires no external ducting or room modifications and satisfies one of the new Annex 1 guidance requirements.

Widely used in NHS hospital pharmacies for the preparation of cytotoxic drugs and as radiopharmaceutical (RAD) models, in Nuclear Medicines Departments, this range of negative pressure isolators has been designed for:

- Reconstitution and dispensing of cytotoxics, gene therapy and other medicinal products that are hazardous to personnel

- Manipulation of radiopharmaceuticals and blood labelling (RAD versions)

- High level containment of biological materials and processing of materials subject to COSHH regulations.

With a choice of two or four gloves, wider or narrower working areas and additional exhaust fans and filters, these high-performance isolators are easy to set up, operate and maintain.