- Home

- Companies

- BRD Noise and Vibration Control, Inc.

- Products

- HUSH BAFFLE - Ceiling and Sound ...

HUSH BAFFLE - Ceiling and Sound Absorbers

Off The Shelf Solutions To Control Ceiling Reflections And Reverberation.

Treatment Strategy

- PathIndirect

- PathDirect

Application Use

- Industrial In-plant

- Industrial New Con.

- Architectural Finishes

- Cleanable

- Lightweight and self-supporting

- Class A flammability ratings

- Standard 2’x4’ size is easy to install

- Other custom sizes are also available

- Light reflective facings help maintain overhead lighting

- Choice of facings for industrial, commercial and architectural applications

- Easily relocated to other areas

- 8 to 12 sabins of absorption per baffle

- Special USDA and FDA “Listed” baffle designs

- Maintenance free

- Standard and custom colors

- Impact resistant constructions are also available

- Pools, gyms and athletic facilities

- Manufacturing facilities and warehouses

- Theatres and auditoriums

- Prison day rooms

- Churches

- Educational institutions

- Band practice and choral rooms

- Airports and mass transit

- Casinos and entertainment facilities

- Special designs for clean rooms, pharmaceutical operations and food processing plants

- Shopping malls

- Large meeting rooms

- Any public assembly area

- Cafeterias and restaurants

BRD HUSH BAFFLES are an effective, economical method of reducing reverberant or reflected noise in rooms and buildings with predominantly hard surface building materials such as wood, glass, plaster, drywall, concrete and metal. Suspended overhead baffles allow for even distribution of large quantities of soft noise absorbing material. By eliminating the reflective contribution back to the source, overall reductions can be in the 4 to 8 dB range. When combined with model HUSH QUILTabsorber blankets on the walls we have actually measured overall reductions as high as 10 to 12 dB although this should be considered the exception and not the rule. BRD HUSH BAFFLES integrate exceptionally well with existing sprinklers, lighting, and heating/air conditioning systems.

- To lower ambient noise levels in reflective environments

- To increase speech intelligibility by reducing “slap echo”

- To lower noise levels in far field away from direct transmission paths

- When enclosures, partitions and direct path control barriers are impractical or cost prohibitive

- To reduce reverberation time

- In “live” reflective spaces where the use of reinforced sound systems are utilized

- To lower noise levels directly next to noisy equipment in the near field

- When 10 dB or greater reductions are required, use direct path barrier treatments instead

- Where sprinkler, lighting and air conditioning operation would be affected

- When reverberation time in the space is already 1 to 1 1/2 seconds

- Do not use HUSH BAFFLES as a direct path enclosure around equipment; use barrier materials instead

Core Materials:

- Fiberglass in 1", 2, 3, 6 & 7 lbs./ft.3 densities

- Fiber free melamine class A open cell foam

Surface Finishes:

- Polyethylene

- PVC

- Polyester fabric

- Perforated vinyl

- Nylon sail-cloth

- Hypalon

- Tyvek

Construction Methods:

- Sewn loose

- Sewn tailored

- Heat sealed loose

- Heat sealed shrink wrapped

Edge Constructions:

- Natural

- Resin hardened

- PVC frame

Suspension Provisions:

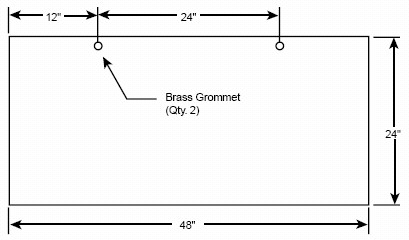

- Grommets

- "D" rings

- Plate hanger

- Eye hook

- Loop

- Strap/saddle

Sizes:

- 2` x 4` standard

- Other standard sizes vary with the product type

- Custom sizes on a quotation basis

Colors:

- A variety of colors are available for each surface finish. Please consult BRD.

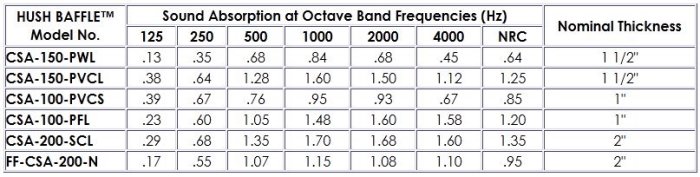

CSA-150-PWL:

- Nominal 1" lbs./ft.3 fiberglass core 1" thick with natural heat sealed loose with grommets

CSA-150-PVCL:

- Nominal 1" lbs./ft.3 fiberglass core 1" thick with natural edge, 2 mil PVC finish, heat sealed loose with grommets

CSA-100-PVCS:

- Nominal 6 lbs./ft.3 fiberglass core 1" thick with natural edge, 2 mil PVC finish, heat sealed shrink wrapped with grommets

CSA-100-PFL:

- Nominal 3 lbs./ft.3 fiberglass core 1" thick with natural edge, standard polyester fabric finish, sewn loose with grommets

CSA-200-SCL:

- Nominal 2 lbs./ft.3 fiberglass core 2" thick with natural edge, nylon sailcloth finish, sewn loose with grommets

FF-CSA-200-N:

- Nominal .7 lb./ft.3 melamine fiber free sculpted foam core 2" thick with natural edge, natural finish and grommets

FF-CSA-300-H:

- Same as above only 3" thick with hypalon finish

- BRD trained sales staff can assist in determining baffle layout designs for optimal performance.

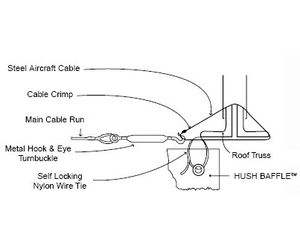

- Size the support cables adding 4’ to 6’ of additional length.

- Attach the support cable with adjustable turnbuckles to overhead beams, roof truss members (see detail at right) or embedded bolt/anchors.

- String the support cable taking care to minimize sag by securing the cable every 10’ to 12’.

- Hang baffles from cables using “S” hooks, nylon ties, monofilament line, etc.

- Adjust tension of each cable using the turnbuckle.

- In some applications cable is not necessary and baffles can be hung directly from existing steel or glued flush to the metal deck underside.

- Baffle installations which are to hang partially or fully below sprinkler heads need to meet NFPA standards for minimum spacing requirements. Please consult your insurance carrier for current requirements.