- Home

- Companies

- Central Steel Manufacturing Co.,Ltd

- Products

- Central - Seamless Steel Pipe

Central - Seamless Steel Pipe

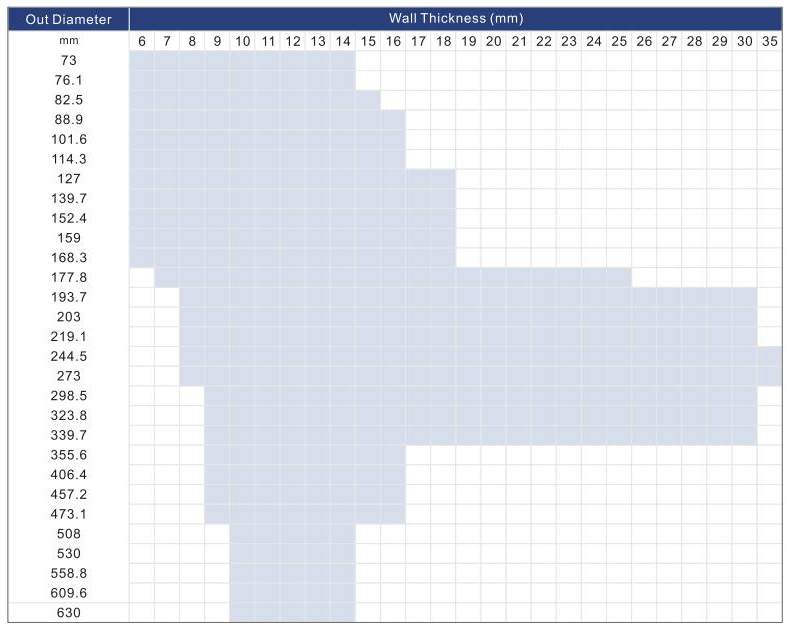

Seamless pipe sizes: 1/2” Nominal to 24”O.D. Seamless Pipe. Wall Thicknesses – Schedule 40 up to 4.000”.

Condition on delivery of seamless pipe

Cold-finished/hard (cold-finished as-drawn)

BK

No heat treatment after the last cold-forming process. The tubes therefore have only low deformability.

Cold-finished/soft (lightly cold-worked)

BKW

After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits.

Annealed

GBK

After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum.

Normalized

NBK

The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum.

Manufacturing Process

Billets and coils are delivered to the pipe mill ready to be made into carbon steel pipe. Depending on the capabilities of the pipe mill and the end use of the final product, the casts will be formed into pipe by means of four distinct different manufacturing. Seamless carbon steel pipe has, as its name implies, no longitudinal weld seam. It is, in essence, one solid homogeneous piece of steel. A solid billet is simply heated and then stretched over a series of mandrels until the pipe has achieved its desired diameter and wall thickness.

Cold drawn seamless tube

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1026 steel tube. Produced from piercing hot rolled bar stock, the cold drawing process increases the tube`s physical properties reducing the cost of machine time. Cold drawn seamless tubing provides a better uniformed OD and ID, enhanced machinability, increased strength, and tighter tolerances compared to hot finish seamless products.

- Made from 1026 steel

- Meet ASTM A519

- Stocked size range: 1.500”OD – 14.000” OD; .250” wall – 1.25” wall

- Stocked lengths 17’-24’

- Cut to length service available

Hot Finished Seamless Mechanical Tubing (HFS) is a 1020/1026 carbon seamless mechanical steel tube commonly produced from a rotating heated bar and pierced to create a hollow tube. HFS tubing is a cost effective alternative to cold drawn seamless tubing with just a broader tolerance range on the outside diameter (OD) and inside diameter (ID). Hot Finished Seamless mechanical tubing is manufactured to OD and wall dimensions.

- HFS tubing is made from 1020/1026 Steel

- Meets ASTM A519 & A106 standards

- Stocked Size Range: 3.00" OD - 26.000" OD; 0.500" wall - 4.000" wall

- Stocked Lengths 17`-40`

- Cut to length service available

Packages of seamless pipe

Bundled package

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles. The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements. When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3. When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2.

- Low temperature service pipes

- Tubes for mechanical and structural

- Tubes for fluid transportation

- Ship building tubes

- Bearing pipes

- Line pipes used in sour service

- Tubes for pressure services

- Pipe for high temperature

- Honed tube

- Boiler tubes

- Heat exchanger tubes

- Marine seamless steel pipe

- Tubes for mechanical and automobile