- Home

- Companies

- Zhengzhou Kerui Industrial Development ...

- Products

- Kerui - Ceramic Fiber Insulation Board

Kerui - Ceramic Fiber Insulation Board

Ceramic fiber insulation board is a insulation material with high-temperature resistant, heat-insulating, thermal insulating, and soundproofing. Therefore, it is widely used in high-temperature insulation applications and kilns. Kerui Refractory has factory with stable production and competitive price. Our partners are from 50+ countries, including Russia, South Korea, Indonesia, Turkey, Oman, Saudi Arabia, Morocco, etc.

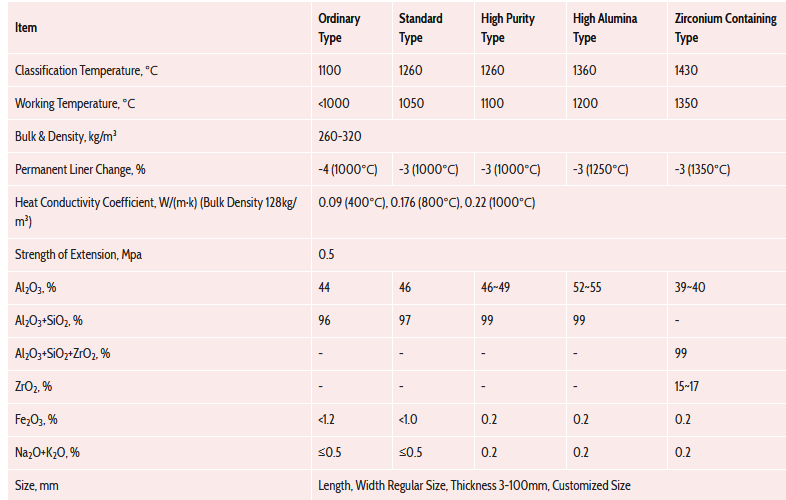

- Classification Temperature: 1100/1260/1260/1360/1430°C;

- Al2O3:39-55%;

- Bulk Density: 260-320g/cm³;

- Heat Conductivity Coefficient: 0.09-0.22W/(m·k);

- Permanent Liner Change: ≤4.0%;

- Length: 600-1200m (customizable);

- Width: 400/ 500/ 600/ 1000/ 1200mm (customizable);

- Thickness: 3-100mm (customizable);

- Shipment: 7-15 working days;

Kerui ceramic fibre sheet is a high-temperature insulation product made from high-performance ceramic fibers. It is made through advanced pressing production. Ceramic fiber insulation boards have numerous advantages, such as insulation, heat resistance, and good mechanical strength. Depending on the composition, Kerui offers standard ceramic fiber boards, high-purity ceramic fiber boards, alumina ceramic fiber boards, zirconia ceramic fiber boards, and other products.

- Production output: 250,000 tons per year.

- Strict quality inspection process: raw material inspection, finished product inspection, physical and chemical property inspection, etc.

- Size: Standard size and customized size supporting.

- Inventory: Large quantities in stock, support immediate delivery.

Competitive Price of Kerui Ceramic Fiber Board

For ceramic fiber boards, Kerui Refractory provides factory prices as refractory supplier. Prices vary for each model and customized products. Additionally, the quantity will also affect the price. Kerui Refractory has an annual production capacity of 250,000 tons and a fully automated production system. We offer competitive prices. If you choose to purchase high temp ceramic fiber boards from Kerui Refractory, product quality and delivery lead time are guaranteed.

Kerui Refractory offers four types of standard and customized ceramic insulation sheets. These sheets have differences in performance based on the different compositions of alumina, silica, and zirconia. Please choose the appropriate types of ceramic fiber products based on specific performance criteria.

High-temperature Resistance

The melting point of high-temperature resistant ceramic fiber board insulation can reach up to 1700 degrees Celsius. It has a strong ability to withstand high temperatures, exhibiting thermal stability and resistance to thermal shock. With a linear expansion coefficient ranging from 4% below 1350?, it maintains a good structure even during rapid temperature changes.

Absorb Sound Waves

The various characteristics of the ceramic fiber insulation board, such as its porous structure, low density, lightweight, and fiber wrapping structure, allow it to absorb, reflect, and reduce the intensity of sound waves, making it widely used in industrial sound insulation applications.

Low Thermal Conductivity

The thermal conductivity coefficient of the fireproof fiber board ranges from 0.09 to 0.22 W/(m·K) between 400-1000ºC. It is lower than dense refractory bricks. This feature effectively reduces heat transfer and achieves thermal insulation. Additionally, with a density between 260-320 kg/m³, it can effectively reduce building weight loads and improve insulation performance.

Strong Processability

The ceramic fiber insulation board is highly processable due to its strong flexibility. It can be altered in size and shape through cutting, shaping, bonding, sewing, and other processing methods to meet the dimensional requirements of different application scenarios. To enhance tensile strength, reinforcing materials such as metal wires can be added to the ceramic fiber board.

Strong Corrosion Resistance

Kerui ceramic fiber insulation board exhibits strong chemical corrosion resistance, with its composition having good chemical stability. Its porous structure and high-temperature stability enable it to withstand corrosion in acidic, alkaline, and neutral chemical environments, maintaining stability in high-temperature chemical reactions.

Environmental Friendly

Environmentally friendly, the high temperature fiber board is a tasteless, non-toxic, eco-friendly material composed of natural ingredients without harmful substances. It does not emit harmful gases at high temperatures during use and can be recycled for reuse after consumption, helping to reduce pollution and waste.

Industrial Chemicals

In the industrial chemicals industry, refractory insulation boards can withstand high temperatures, thermal shock, and chemical corrosion. They are widely used in the steel smelting industry, ceramic industry, glass industry, power industry, chemical industry, defense industry, semiconductor industry, and more. They are commonly used in furnaces, gaskets, linings, seals, converters, parts, and so on.

Construction and Transportation

In the construction and transportation industries, ceramic fiber boards have excellent thermal insulation and fire resistance properties. They are used in the construction industry, automotive industry, maritime industry, aviation industry, and more. They are used in building walls, roofs, fireplaces, engine heat shields, exhaust pipe insulation sleeves, turbocharger heat shields, cabin insulation materials, and so on.

Firefighting

In the firefighting industry, ceramic fiber thermal insulation boards can effectively provide fire insulation. They are used in the construction of fire protection equipment, such as fire doors, firewalls, firefighting clothing, firefighting blankets, firefighting vehicle heat shields, fireproof rolling shutter doors, and so on.