- Home

- Companies

- Messinger Engineering

- Products

- Model CM01 - Ceramic Membrane Test ...

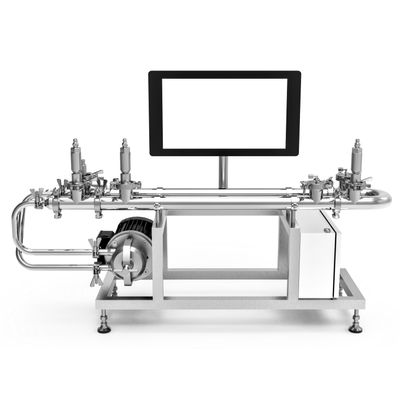

Model CM01 -Ceramic Membrane Test System

High-precision sensors are installed that ensure accurate and reliable measurements.

Open-source software allows for continuous refinement, expansion, and integration to meet future needs. This software adapts to your requirements, rather than forcing you to adapt to it.

The accuracy of the system is astonishing. The system allows an enormously good scaling-up capability from laboratory to industrial scale. An overview of processes with ceramic membranes in the food sector: → Processes

Data acquisition, evaluation, interpretation and fully automated reporting with easy-to-understand graphics make it easier to recognise correlations.

The pipework system is designed in accordance with ASME BPE recommendations. The consistent use of standardised fittings ensures consistent modularity, so that the basic system can be expanded into a mini-plant of any complexity, an interconnected system with additional process engineering equipment and analysers.

Cleaning and maintenance: Simple and effective cleaning and maintenance procedures are implemented to avoid contamination and ensure the reliability of the system.

The ceramic membrane test system CM-1 is compatible with all multi-channel elements from all manufacturers offering ceramic membrane elements with diameter 25 mm, length 100...1200 mm, channel diameter: 1.5...6 mm. We will be happy to advise you on the selection of suitable membrane products for your process / system.

Ceramic microfiltration and ultrafiltration elements offer improved chemical and thermal resistance and a longer service life compared to polymers. The porous membranes are made of ceramic materials such as aluminum oxide (Al2O3), zirconium oxide (ZrO2), silicon carbide (SiC), titanium dioxide (TiO2), etc. These materials are used to produce membranes in various shapes such as tubes, plates, discs or multi-channel elements.

In all ceramic modules, the feed flows through the inside of the channels, while the permeate flows through the support layer around the lumens in the monolith and to the outside of the element. In industrial systems, several individual elements are assembled in one housing, and severals housings are placed in parallel in a unit.