- Home

- Companies

- Chanderpur Works Pvt. Ltd.

- Products

- Chanderpur - Shoe Slide Ball Mill

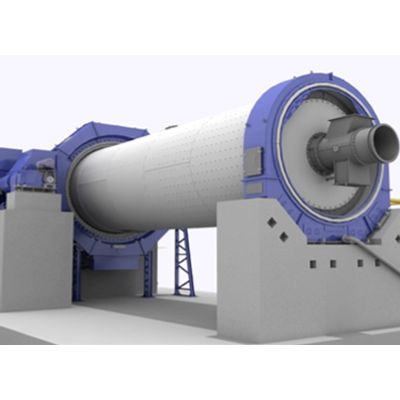

Chanderpur - Shoe Slide Ball Mill

In collaboration with Christian Pfeiffer Germany. Tin based slide shoes with 81% of tin for Higher thermal connectivity, Higher compression strength, Higher fatigue and impact strength, Higher corrosions resistance. Built in Hydraulic jacks for easy maintenance and replacement. No delicate large size mill head castings are necessary. Large feed and discharge openings allowing the passage of considerable amounts of gas.

Highlights

- 450+ installations

- Robust & Reliable Design

- Easy Maintenance & Operation

- Manufacturing upto capability : Dia: 5.0 and Length: 19 mtr

- Fully automated system with PLC control & Instrumentation

- 100% spare availability in any part of world

Successful Installation in

- Grey & White Cement

- Limestone

- Coal

- Chrome Ore

- Iron Ore

- Silica Manganese

- Phosphate

- Slag

- Pet coke

- Alumina

Selection of a Ball Mill

Selection of Ball Mill is done as per product quality, fineness, nature of raw material, site conditions and specific requirements like:-

- Open circuit or closed circuit

- Slide shoe bearing or Trunion Bearing

- Wet or Dry Grinding

- Central Drive or Girth Gear Pinion Drive

Widely recognized for its resilient designs, CPG comes with different designs for both wet as well as dry grinding. CPG can offer two types of bearing design of Ball mill: