- Home

- Companies

- Europress Umwelttechnik

- Products

- Europress - Model HP 180 - Channel ...

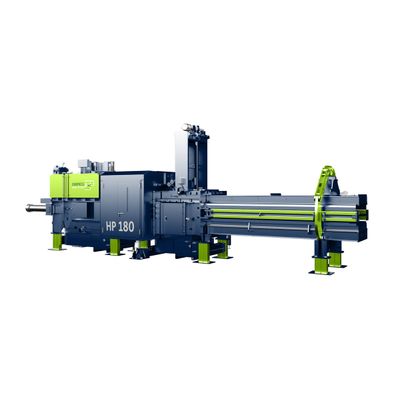

Europress - Model HP 180 -Channel Balers with Wire Tying

Thanks to various additional functions that allow adaptation to specific challenges, our channel balers with wire tying in the HP series prove to be particularly versatile and powerful in use. If required, each baler can be equipped with, among other things, a high-speed main cylinder for energy saving or be protected against wear and tear by a Hardox full equipment. Operation by remote control also makes work easier, with the highest possible level of security thanks to the key transfer system fitted as standard. Our HP models are individually equipped to master demanding tasks in waste compaction in a customer-oriented manner.

- Tying:

- 4-Fold Horizontal

- 5-Fold Horizontal high-rise format

- 5-Fold Vertical

- 5-Fold Vertical + 3-Fold Horizontal

- Press force: 180 Tons

- Filling opening: 1.000 x 2.000 mm

- Channel cross-section: 750 x 1.100 mm

- Drive power: 45 - 3 x 75 kW

- Bale weight: 600 - 900 KG

- Bale length: up to 2.000 mm

- Machine length: 13.900 mm

- Machine width: 2.450 mm

- Machine heigth: 4.250 mm

- Machine weigth: ca. 36 Tons

Weight capacity depending on bulk weight [theoretically] in tonnes per hour

- 20 - 30 kg/m³: 5 - 30

- 35 - 50 kg/m³: 9 - 50

- 60 kg/m³: 10 - 60

- 100 kg/m³: 17 - 100

For closing the press plate during the pressing process so that no material enters the lance guide slots. Hydraulically driven closure plate mounted on the press plate.

This closes the needle slots during the press stroke. These needle slots are only opened during the tying process.

As a result, we guarantee a wire-crack-free workflow and reduced cleaning and maintenance intervals.

For closing the bottom during the pressing process so that no material gets into the lance guide slots. Hydraulically driven closure plate installed under the bottom wear plates.

This closes the needle slots in the press floor during the press stroke. These needle slots are only opened during the tying process.

As a result, we guarantee a wire-crack-free workflow and low cleaning and maintenance intervals.

Perforator for perforating and squeezing PET bottles, retractable from the side or rear.

The perforator is equipped with two drums that rotate in reverse direction shortly after each other and are equipped with over 1000 spikes

The spikes are aligned so that the bottles are not trapped between them.

WEP whirler retractable from the rear on a console with a drive power of 22 kW.

This allows smooth surfaces, for example of catalogs, to be broken, so that better compaction is possible.

10 mm thick inner lining of the entire bale chamber made of wear-resistant steel in bolted design.

Special equipment for artificial mineral fibresEquipment package to equip the duct baler ready for approval for the compression of artificial mineral fibers.

For closing the press plate during the pressing process so that no material enters the lance guide slots. Hydraulically driven closure plate mounted on the press plate.

This closes the needle slots during the press stroke. These needle slots are only opened during the tying process.

As a result, we guarantee a wire-crack-free workflow and reduced cleaning and maintenance intervals.

With its technically sophisticated but easy-to-use additional functions, the HP series is excellently equipped for applications under difficult conditions or with specific targets that require, for example, variable tying, a strong reduction in wear or an analysis system for higher safety. Through individual consultation, we always find the right solutions for our customers that fully meet the requirements in waste compaction. As an alternative to the HP series, we provide our customers with the slim standard variant.

- Pressing force between 100 and 180 tons

- Stable construction of the base frame

- Height adjustability of the press shield

- Piston- and bottom sliders

- Cardanic suspension of the main cylinder