Hose Master LLC

- Home

- Companies

- Hose Master LLC

- Products

- ChlorSafe - Corrugated Chlorine ...

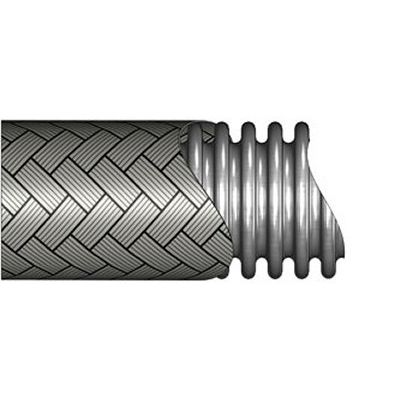

ChlorSafe - Corrugated Chlorine Transfer Assembly

FromHose Master LLC

Hose Master’s 276 alloy, corrugated chlorine-transfer assembly, designed to meet the demands of this application. With considerations made for both wet and dry chlorine, these assemblies are the safest available. ChlorSafe™ assemblies are manufactured in compliance with the Chlorine Institute Pamphlet 6, Appendix A, latest edition.

Most popular related searches

helium mass spectrometry

chlorination

mass spectrometry testing

transfer hose

mass spectrometry

helium leak detection system

spectrometer

helium test

Braid Codes:

- 20 – C276 Single Braid

- 22 – C276 Double Braid

Example: AF6760 = 276 annular corrugated metal hose with a single C276 Braid.

- Hose Master’s proprietary manufacturing process reduces residual stress and produces the most flexible chlorine transfer hose available

- ChlorSafe’s™ all metal construction makes it fire resistant

- Proprietary welding techniques provide a smooth transition from hose to fitting with no gaps or crevices to entrap contaminants

- All welds are argon-purged to eliminate oxidation

- All wetted surfaces and the braid are made from UNS N10276 (referred to as either C276 or 276 alloy) which has the highest chemical resistance rating for both dry and wet chlorine 1

- Every assembly is helium mass spectrometer leak tested to at least 5.0 x 10-6 std cc/sec.

- Each assembly is covered by a stainless steel interlocked metal hose for maximum durability

- All assemblies strength tested to twice maximum allowable working pressure

1 Kenneth M. Pruett, Chemical Resistance Guide for Metals and Alloys: A Guide to Chemical Resistance of Metals and Alloys (Derby: Compass Publications, 1995), 93.