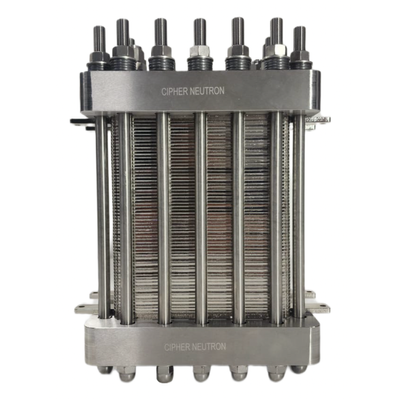

Cipher Neutron - AEM Electrolyser

The AEM Electrolyser stands out as a groundbreaking technology for green hydrogen production, leveraging Anion Exchange Membrane (AEM) electrolysis. This advanced process involves the migration of negatively charged hydroxyl ions (OH-) through the AEM, while simultaneously blocking positively charged ions (H+). The captured protons (H+) form green hydrogen gas at the cathode, while hydroxyl ions (OH-) on the anode create water and oxygen gas. Unlike traditional Proton Exchange Membrane (PEM) and Alkaline electrolysis technologies, AEM Electrolysers can achieve high-pressure outputs up to 30 bar and produce hydrogen gas with an extraordinary purity level of 99.9%. These efficiencies are realized without relying on Platinum Group Metals (PGMs) or other toxic and environmentally harmful substances. This makes AEM Electrolysers not only highly efficient and cost-effective but also sustainable and environmentally friendly. Cipher Neutron leads the way in promoting this innovative technology, positioning itself at the forefront of clean and renewable energy solutions. The longevity of AEM Electrolysers reduces the need for frequent repairs and minimizes downtime, thereby lowering overall process costs. Their modular and compact design allows for scalability, making them suitable for diverse project sizes. The ongoing concerns regarding PFAS and regulatory pressures highlight the urgency for PFAS-free technologies. AEM Electrolysers represent a safer, more sustainable alternative in the green hydrogen industry, setting the stage for prolonged advancements and adaptations in an ever-evolving landscape.

⦁ Hydrogen pressure : Up to 30 bar

⦁ Hydrogen purity without additional purification : Up to 99.9%

⦁ Hydrogen purity with additional purification : Up to 99.999%

⦁ Feed water quality : ASTM Type 1

⦁ Feed water pressure : 2 to 6 bar

⦁ Feed water temperature : 5° C to 40° C

⦁ Nominal power consumption, beginning of life (BoL) : 4.54 kWh/Nm3 at stack level

⦁ Amperage at nominal operating voltage, beginning of life (BoL) : >700mA/cm2

⦁ Amperage at 2 volts per cell, beginning of life (BoL) : >2 000m A/cm2

⦁ Average cell voltage at end of life (EoL) : 2.2V

⦁ Electrolyte type : 1M KOH

⦁ Range of operation : 20% to 120%

⦁ Membrane crossover concentration (%) : < 0.001 mL/min.cm2

⦁ Ambient operative temperature range : 5° C to 40° C

⦁ Waste recovery system : optional