- Home

- Companies

- ClearStream Environmental Inc.

- Products

- ClearStream - Drive Units

ClearStream - Drive Units

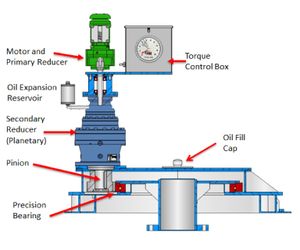

Design Features: Designed using modern fabricated steel vs. cast iron. Allows for flexibility of design and quick fabrication. Designed around commercially available components. Drive components are commercially available almost anywhere in the world. Designed using precision-ground, 4-point contact, integral gear/bearing. Over 175,000 hours (20 years) AGMA gear life. Over 100 years bearing life. Designed without lower pinion bearing. Greater drive unit reliability. Large, accurate, hydraulic torque gauge calibrated in units of torque.

- Cage Drives

- Shaft Drives

- Dual Cage Drives

- Dual Shaft Drives

- Cage Drives w/Lifts

- Shaft Drives w/Lifts

- Direct Cage Drives

- Direct Shaft Drives

- Multi-Pinion Cage Drives

- Multi-Pinion Shaft Drives

- Hydraulic Drives

- Four-point contact precision main bearing, evenly distributes overturning loads.

- Steel housing / Designed to bolt-up to any existing unit for retrofit.

- Designed per AGMA and ABMA standards for minimum 100 year bearing life.

- No lower pinion bearing required.

- Primary parallel helical gearmotor with shear pin.

- Secondary planetary speed reducer with pinion mounted on output shaft.

- Precision gear, grease or oil lubricated.

- Hydraulic Torque Box with Dial Indication.

- 5-year Warranty (less motors and paint)

- 10-year Warranty Main Gear

- Stainless Steel or Ductile Cast Iron Drive Housings are options

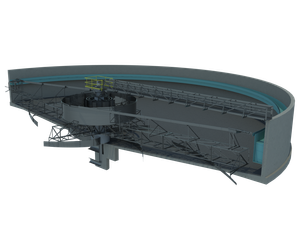

ClearStream produces a 3D model of every unit which we manufacture. These models are extremely valuable to ensure proper fit up. In addition, these models can be a useful tool for operators training and understanding of the unit design and operation. ClearStream provides these 3D models as well as the means for clients to view and manipulate these models at their own site or offices. This affords operations and maintenance personnel with a unique opportunity to “inspect” the unit prior to any planned maintenance without having to drain the tank.

- Drive Retrofits of other brands.

- Drive Replacements of other brands.

- Heavy Duty Drive Units for High Torque applications.