- Home

- Companies

- Consolidated Laundry Machinery (CLM)

- Products

- CLM - Model 105 - Dryer

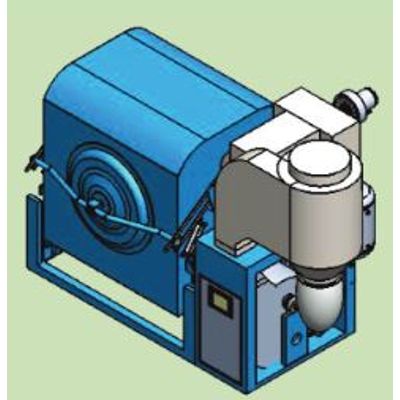

CLM - Model 105 -Dryer

Basket: The 105 cu. ft. basket frame is constructed of top quality 10-gauge steel with three main lifting ribs, three secondary lifting ribs, and six removable perforated panels for trouble-free maintenance. The basket is supported by four 10" polyurethane rollers and guided at both ends by four 5" polyurethane rollers. All CLM wheels are equipped with Timken roller bearings and located outside of the sealed heating chamber.

Basket Doors

Consolidated`s revolutionary basket door seals to and rotates with the basket to prevent damage to products being dried. The doors operate by an air over oil mechanism for smooth opening and closing. Standard models include two basket doors providing for loading at one end and unloading at the opposite end of the basket. Load door diameter options include 42" or 48".

Basket Drive

The basket is driven by v-belts around the circumference of the basket. There is a self-adjusting, constantly variable tension device to keep the belts properly tensioned. The belts and basket drive are located outside of the sealed heating chamber and include an inverter for slower basket start-up and reversing.

Machine Tilt

The main housing tilts to 12º with a maximum of 18° facilitating fast and easy loading and unloading of the machine. The tilt mechanism contains two 5" ID double-cushioned air cylinders.

Lo-NOx Heat System

A high-efficiency burner is coupled to a full flame spectrum modulating system with fixed air to gas mixing for proper combustion before entering the drying chamber. The combustion chamber is constructed of a steel inner chamber with a steel outer jacket separated by a cooling space using the intake air as an insulator and to pre-heat the incoming air. Maximum firing rate of the burner shall be 1,050,000 btu/hr and average firing rate shall be 750,000 btu/hr at 15" wc pressure.

Heat Control

The flame modulation and temperature is PLC controlled and programmed to heat by inlet/outlet temperature, automatically or by time. Cool-down is also controlled by time or to programmed temperature.

Exhaust System

The exhaust blower is single inlet, dynamically balanced and belt driven from a 10 hp motor to afford a maximum air flow of 6,000 cfm. Included is a device to automatically clean accumulated lint from the rotor at the beginning of each cycle.

Standard Outside Air Makeup

A means of providing makeup air directly to the burner and combustion chamber from the outside to prevent negative air pressure within the plant. The inlet duct has an inside diameter of 15" x 32.5".

Electric Motors

- Exhaust blower 10 hp

- Basket drive 3 hp

- Burner blower 1/3 hp

SERVICESElectricity

- Varies with voltage characteristics

- 60 FLA at 230 VAC

- 30 FLA at 460 VAC

Air

- 1/2” npt connection

- 80 psi minimum

Water

- 3/4” npt connection

- 80 psi minimum

Gas

- 2” npt connection

- 15” wc minimum

Exhaust Duct

- Minimum 24" diameter or 460 sq. in.

- Maximum 1.0" wc backpressure

- 105 cu. ft. vol. Basket

- Compact Gas Heated

- Two-Door Pass-Through

- One-Way Tilt

- PLC Control

Recommended Capacity

200-300 lbs. Dry Weight