Clorel® - On-site Seawater Electrochlorination

Clorel® SEA Seawater Electrochlorinators are using only seawater and electricity to produce Sodium Hypochlorite (NaOCl) for any kind of marine biofouling prevention in seawater cooling and marine applications. Using the unlimited salt source of seawater with optimum electric consumption makes it unquestionably the best marine biofilm control solution.

The Best Way! for Biofouling Control

Clorel® SEA is replacing Chlorine Gas, Commercial Sodium Hypochlorite and Biocides. It immediately eliminates high safety risks, high chemical costs, chemical transportation, etc. Clorel® SEA is an onsite chlorination solution for all kinds of chlorination requirements of seawater.

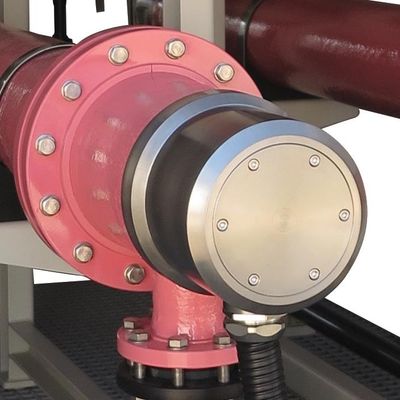

An Electrolyzer

Clorel® SEA technology is an electrolysis process of Salt (NaCl), Water (H2O) and Electric energy. The ion exchange chemistry between the unique Clorel® SEA Anode and Cathodes, allows us to produce Sodium Hypochlorite (NaOCl) only with seawater and electricity.

A Sodium Hypochlorite (NaOCl)

Clorel® SEA produces Sodium Hypochlorite (NaOCl) at a chlorine concentration of 2gr/lt. So the end product is a seawater-based NaOCl with 2gr/lt Cl2 concentration.

Less than 1% Chlorine (Cl2) Concentration

Clorel® SEA contains only 2 grams of Chlorine-Cl2 per liter and is therefore exempt from the hazardous substance class and all relevant sanctions as it is below 1% concentration according to EPA and WHO standards.

An Onsite Production

Clorel® SEA Seawater Electrochlorinators are designed to produce where consuming is; so, it is an on-site solution that locally produces the required amount according to live demand. Clorel® SEA is not designed to produce NaOCl and transport due to its

A Liquid

2gr/lt concentrated Sodium Hypochlorite is a liquid of light-yellow colored and slightly smells like Sodium Hypochlorite.

Naturally Low pH - 8,5-9,5

The pH value of Clorel® SEA is only between 8,5 - 9,5; which is close to water and far from commercial Sodium Hypochlorite(pH12-13) and also Gas Chlorine (pH <4).

Clorel® SEA capacities will be set depending on your needs. Let us help you to choose the right capacity and enhance your current chlorination solution.

Endless Capacity

Clorel® SEA capacity will be set totally regarding your chlorination requirements. From 1kg/hr production capacity to unlimited requirements, Clorel® SEA has a limitless range for capacity that will answer your chlorination needs.

Advanced PLC

Management of the system in CLorel® SEA is easiest and most restrained with its modern graphical user interface and powerful hardware and software infrastructure. PLC management of Clorel® SEA is the unquestionable leader in electrochlorination market.

Full Automatic Cleaning

Hardness depositing on electrodes is an unavoidable fact by its very nature of electrolysis process, Periodic acid washing to clean these deposits is enhanced in Clorel® Sea with its Superior PLC features. Fully automatic, one-touch washing operation from the PLC offers the user the easiest acid washing comfort through the market.

Heavy Duty Equipment

Operating 365/7/24 with seawater is a serious process which requires the highest quality pieces of equipment and instruments. Kemisan guarantees to offer the best and toughest of them that will work flawlessly in the long run.

Optimum Consumption

High efficient Cell design of Kemisan enables to consume as low as 3,5kW of electricity per 1 kg of Cl2 production which is vitally important for operational costs and return on investment.

Hybrid Tubular Cell

Clorel® SEA, with its more than 45 years of experience and R&D investments, offers the ability to observe the cells whenever needed, thanks to its FRP and Acrylic Construction Hybrid cells.